Gantry machining lathe

A technology for processing machine tools and gantry, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of abnormal temperature rise of rolling bearings, abnormal temperature rise of cylindrical roller bearings, and poor lubricant discharge, etc., to achieve Avoid micro-centrifugation, good centering performance, good centering performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

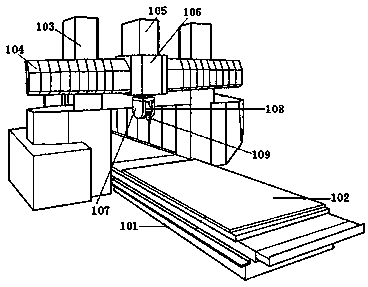

[0030] see figure 1 , shows the gantry processing machine tool of the present invention.

[0031] The gantry processing machine tool includes a machine platform 101 and a worktable 102 that can slide back and forth on the machine platform 101. Columns 103 are respectively arranged on both sides of the rear end of the machine platform 101, and a vertical moving part 104 is movably arranged on the On the column 103, a driving part (not shown) can drive the vertical moving part 104 to move vertically on the column 103. Optionally, the vertical moving part 104 is a horizontal column.

[0032] The vertical moving part 104 is provided with a left and right moving part 106 that can move left and right, and the left and right moving part 106 is provided with a power part 105 that can drive it to move, thus, through the workbench that can move back and forth, it can vertically The vertical moving part that moves, and the left and right moving part that can move left and right realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com