hot melt adhesive

A bonder and hot-melt technology, which is applied in the field of welders, can solve the problems of difficult to guarantee the firmness of bonding and long curing time, and achieve the effects of fast curing speed, high connection strength and increased bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

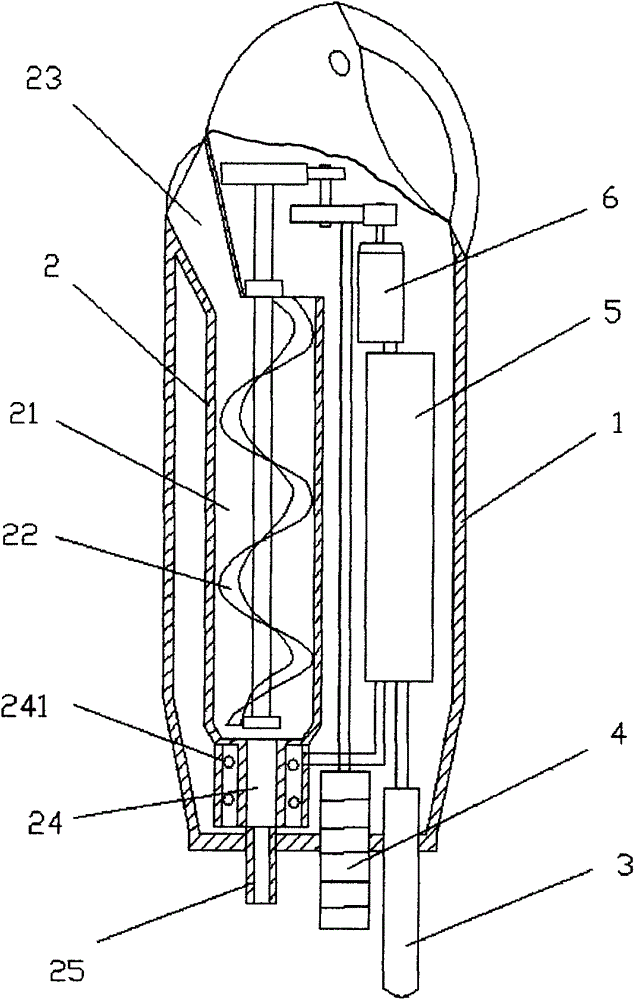

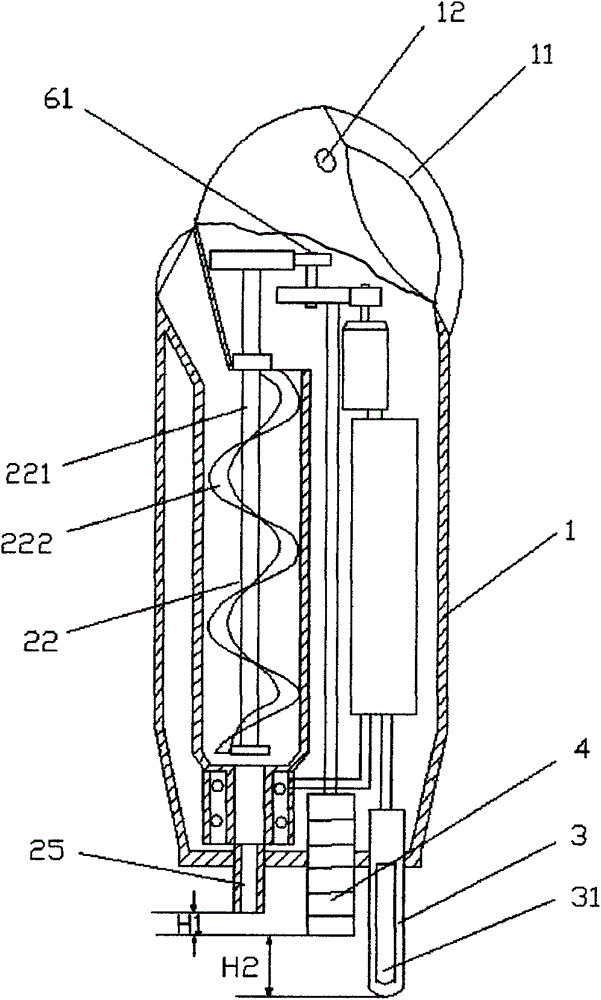

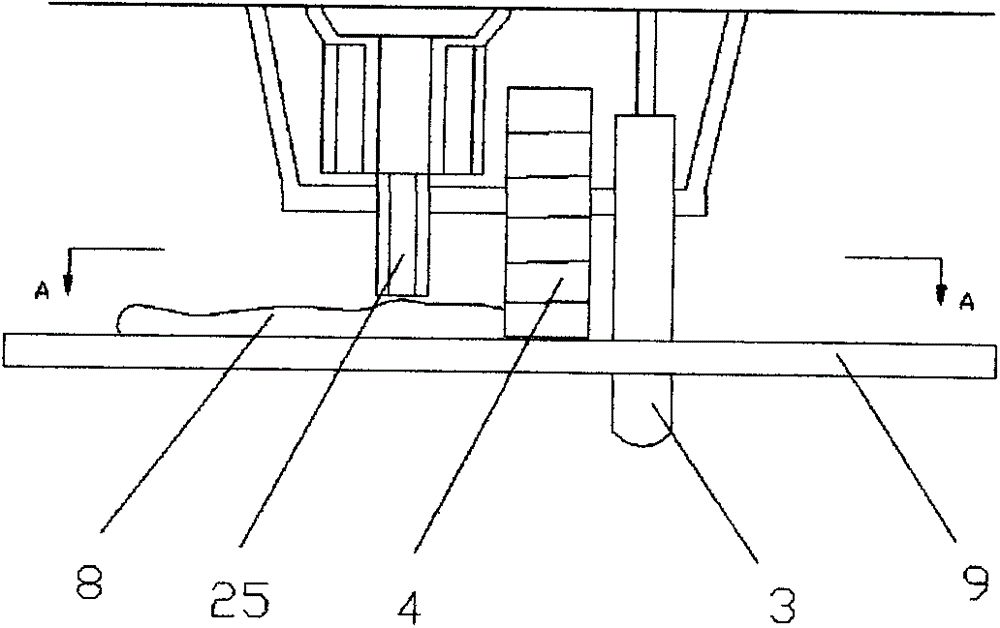

[0023] Such as Figure 1-4 As shown, a hot-melt adhesive device of this embodiment includes a housing 1, a handle 11 is provided outside the housing, a hot-melt device 2 is arranged inside the housing, and a spiral body 22 is arranged inside the trough 21 of the hot-melt device. The spiral body 22 is composed of a spiral shaft 221 and a spiral blade 222 welded on the shaft, and is connected with the gear set 61 driven by the motor 6 to generate rotation. A feeding port 23 is provided above the trough 21, and plastic foam is put in from the feeding port, and pushed into the melting tank 24 connected with the bottom through the spiral blade 222 of the spiral body. An electric heating tube 241 is arranged on the periphery of the melting tank. The discharge port 25 is arranged in a straight line with the weldment 3, and protrudes outside the housing 1. On both sides between the weldment 3 and the discharge port 25, there are two counter-rotating valves that are also exposed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com