Carburization process for heavy machinery part

A technology for heavy machinery and parts, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as grinding cracks, cracks or peeling, and reduce the service life of heavy machinery parts, so as to achieve brittleness The effect of improving the fracture resistance, reducing the surface tensile stress, and reducing the tendency of quenching cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

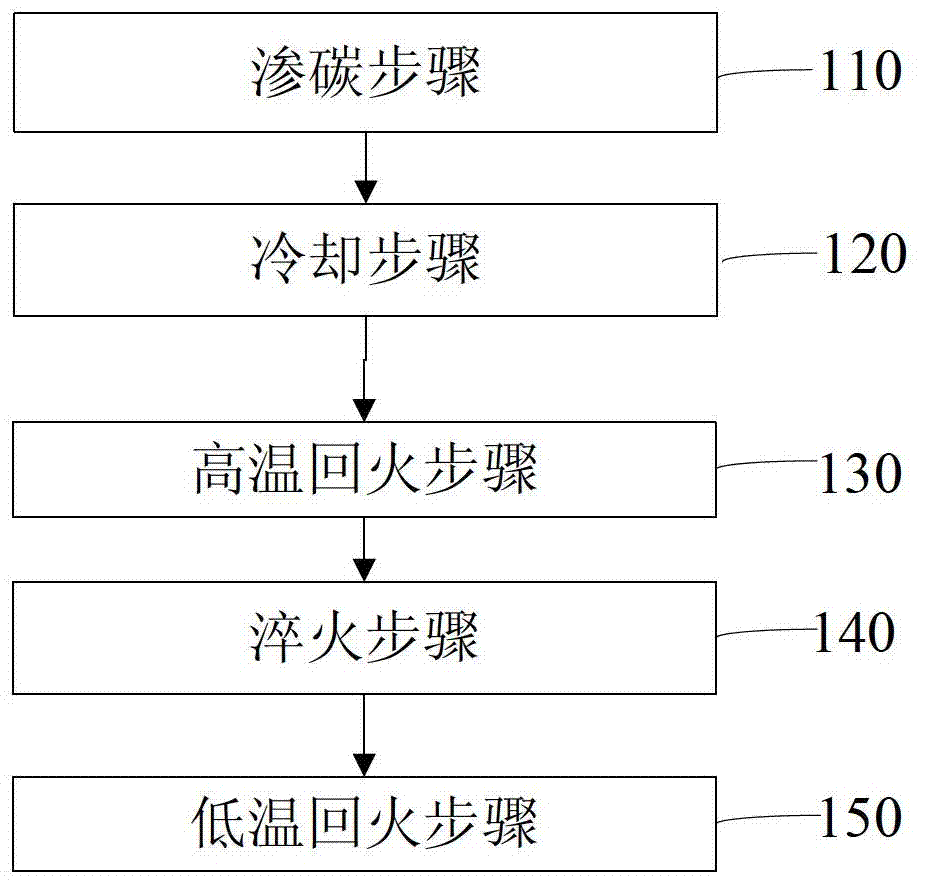

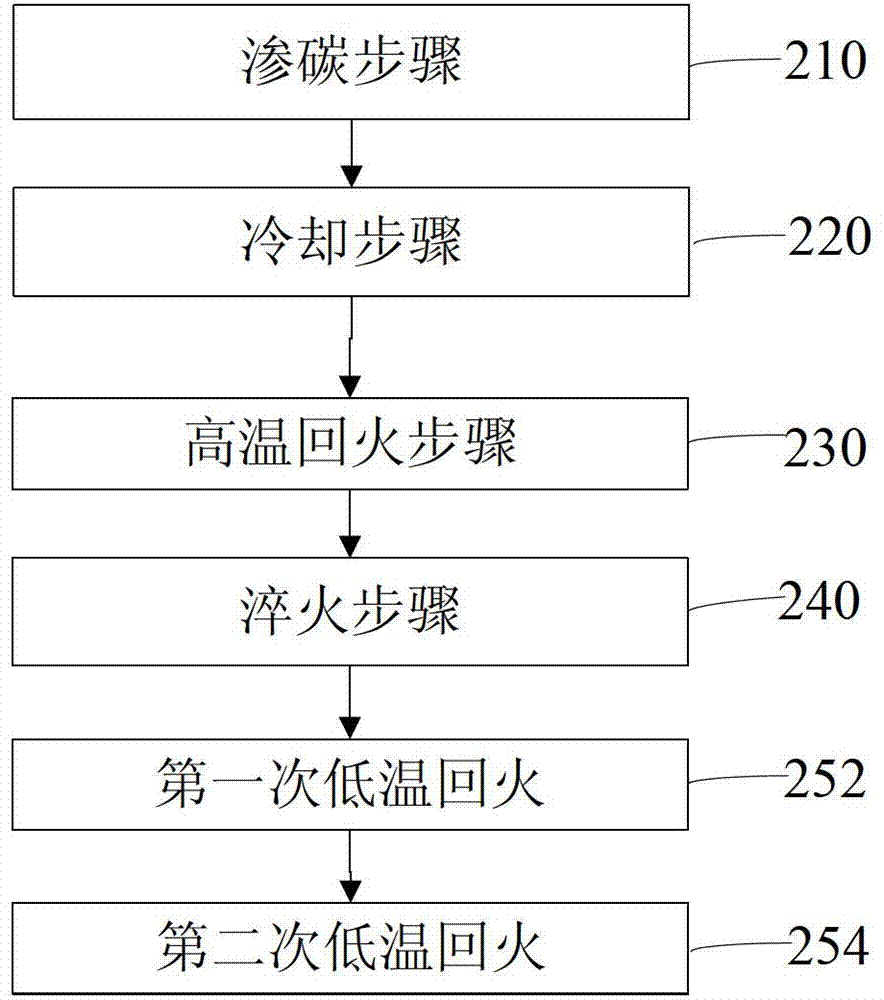

[0015] figure 1 It is a schematic flow chart of the carburizing process of heavy machinery parts according to the first embodiment of the present invention. Heavy machinery components such as heavy-duty gear shafts. In this embodiment, the heavy-duty gear shaft is, for example, a 20CrMnMo heavy-duty gear shaft. 20CrMnMo is a high-strength carburizing steel, and its main components are (by mass percentage): 0.90-1.20% manganese (Mn), 1.10-1.40% chromium (Cr), 0.20-0.30% molybdenum ( Mo) 0.17-0.23% carbon (C) and 0.17-0.37% silicon (Si).

[0016] Before carburizing parts such as 20CrMnMo heavy-duty gear shafts, preparatory steps for carburizing parts are required. For example, forging, post-forging normalizing, rough turning, quenching and tempering, turning outer circle, both end faces, center hole, addendum circle, gear hobbing and surface cleaning are performed sequentially according to design requirements, which will not be described in detail here. In addition, post-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com