Specky fabric and manufacturing method thereof

A production method and fabric technology, applied in textile decoration, textile and papermaking, fiber treatment, etc., can solve the problems that fabrics cannot meet consumers' fashion, comfort, and functional requirements, and achieve obvious spot effects and maintain breathability Effects on sex and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

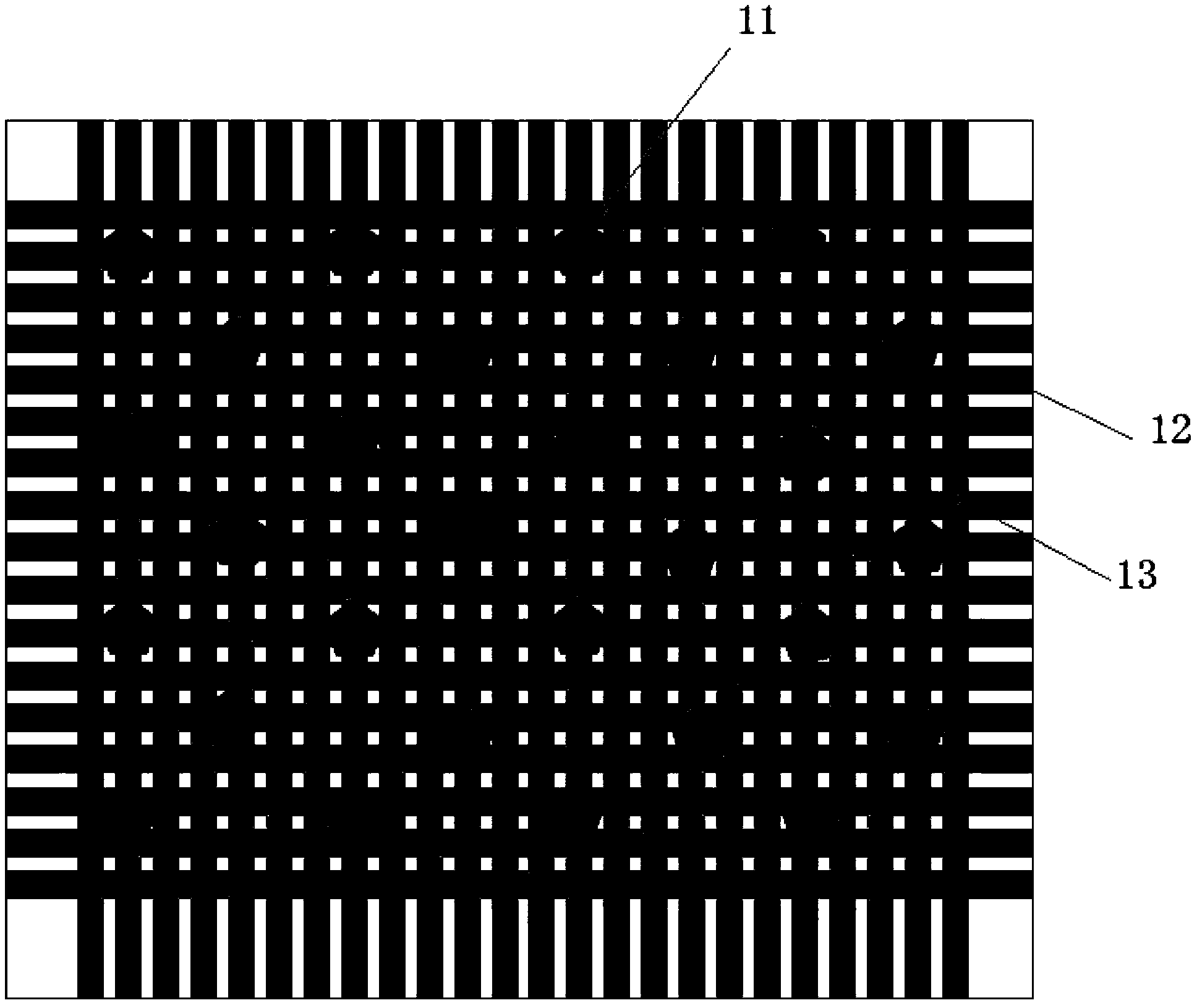

[0037] Yarn adopts 20D nylon raw silk, the fabric type is plain weave, the density of warp yarn 13 is 210 yarns / inch, and the density of weft yarn 12 is 180 yarns / inch. After desizing and dyeing, the fabric is water-proof and shaped, and then hot-melt adhesive dot compound coating is carried out on the hot-melt adhesive coating compound machine. PUR hot-melt adhesive and TPU transparent film are used. The gap between the rubber rollers is 0.1-0.2mm during coating. , Composite roller gap 0.1±0.05mm, so that the coating amount of glue is between 12-14g / m, compound speed 10m / min, center coiling speed 9.5m / min, aging conditions after compounding: temperature 38 ℃, humidity 90% , time 48 hours.

Embodiment 2

[0039] The yarn adopts 15D nylon raw silk, the fabric type is plain weave, the warp yarn density is 200 yarns / inch, and the weft yarn density is 170 yarns / inch. After desizing and dyeing, the fabric is water-proof and shaped, and then hot-melt adhesive dot compound coating is carried out on the hot-melt adhesive coating compound machine. PUR hot-melt adhesive and TPU transparent film are used. The gap between the rubber rollers is 0.1-0.2mm during coating. , Composite roller gap 0.1±0.05mm, so that the coating amount of glue is between 12-14g / m, compound speed 15m / min, center coiling speed 14.5m / min, aging conditions after compounding: temperature 40℃, humidity 90% , time 43 hours.

Embodiment 3

[0041]The yarn adopts 15D nylon raw silk, the fabric type is plain weave, the warp yarn density is 200 yarns / inch, and the weft yarn density is 170 yarns / inch. After desizing and dyeing, the fabric is water-proof and shaped, and then hot-melt adhesive dot compound coating is carried out on the hot-melt adhesive coating compound machine. PUR hot-melt adhesive and TPU transparent film are used. The gap between the rubber rollers is 0.1-0.2mm during coating. , Composite roller gap 0.1±0.05mm, so that the coating amount of glue is between 12-14g / m, compound speed 13m / min, center coiling speed 12.5m / min, aging conditions after compounding: temperature 42 ℃, humidity 95% , time 53 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com