Non-workover pump detection device for electric submersible pump

An electric submersible pump and workover technology, which is applied in wellbore/well components, earthwork drilling, etc., can solve the problems that the electric submersible pump cannot be stably suspended and fixed, and the electric submersible pump needs to take out the oil pipe column by column.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0040] The electric submersible pump inspection device without workover machine of the present invention starts from changing the pump hanging mode of the current electric submersible pump, and changes the electric submersible pump to be hung on the middle and upper part of the oil pipe instead of being screwed on the lower end of the oil pipe. The pump inspection operation can be completed by using steel wire rope to lift out from the tubing and run into the electric submersible pump.

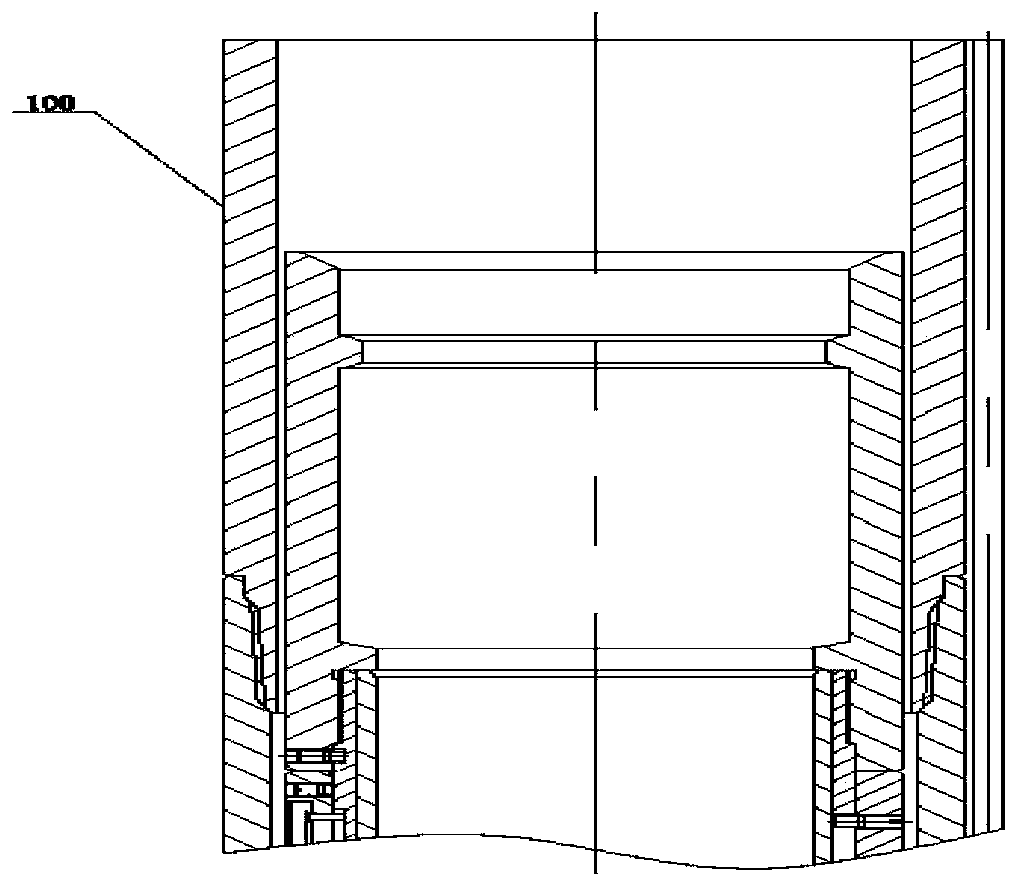

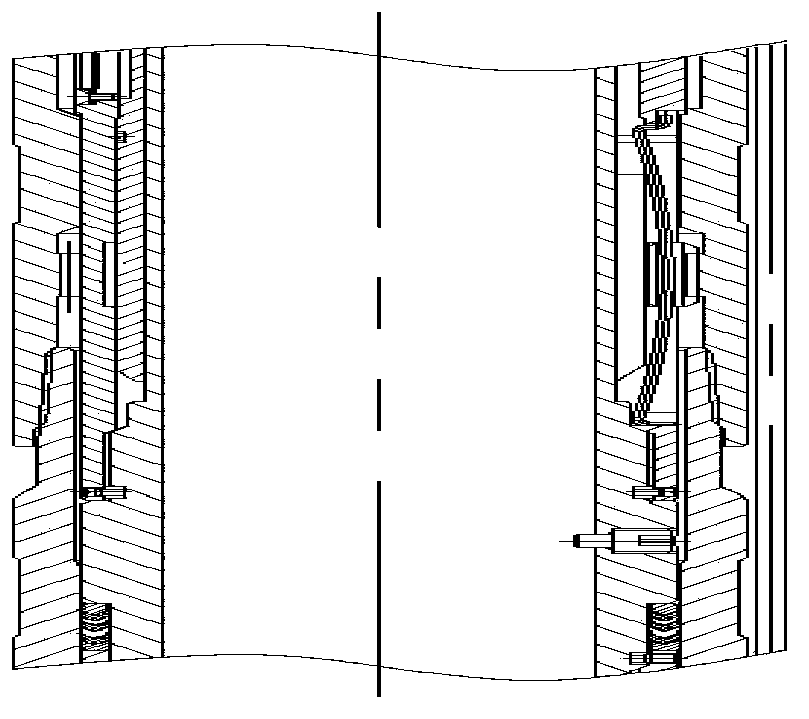

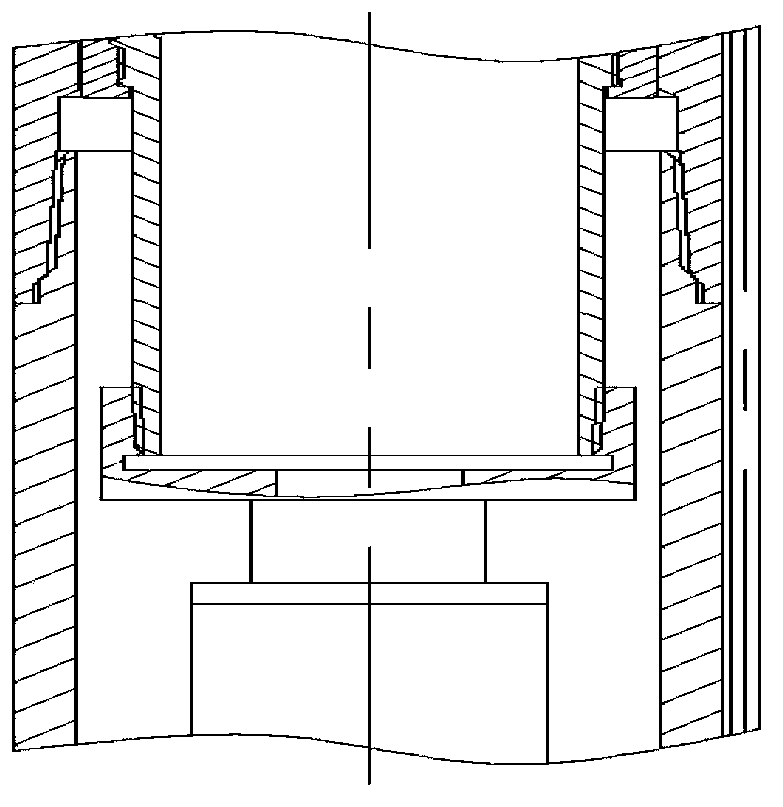

[0041] see Figure 1a-Figure 1j , Figure 2-Figure 9 , Figure 10a-Figure 10f , Figure 11-Figure 15 , Figure 16a-Figure 16c , Figure 17-Figure 19 , a pump inspection device for an electric submersible pump without a workover rig, comprising an oil pipe 100 and a well entry string, and the well entry string is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com