Drying method of inorganic fireproof insulation plates in buildings

A thermal insulation board and inorganic technology, applied in the direction of drying, heating to dry solid materials, drying solid materials, etc., can solve the problems of slow water discharge, surface pulverization, and reduced drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

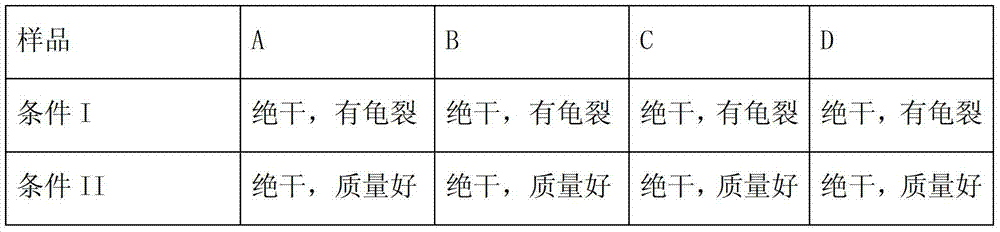

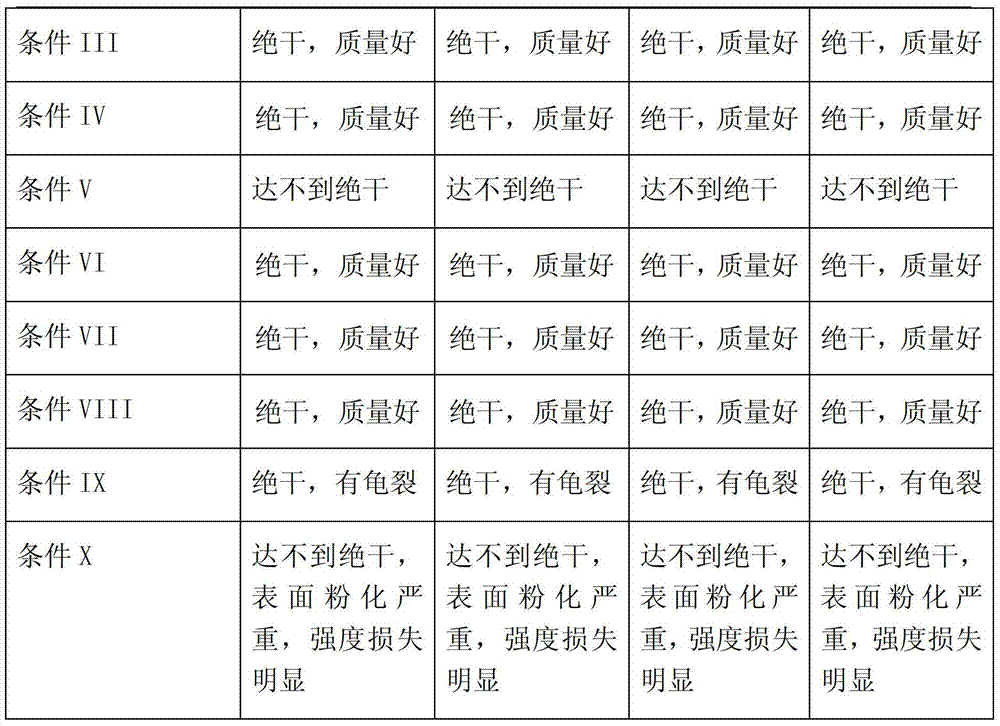

[0017] The drying method of the inorganic fire-proof and heat-insulating board of the present invention will be further described below in conjunction with some specific implementation methods. The specific examples are to further describe the present invention in detail, without limiting the protection scope of the present invention.

[0018] The above-mentioned drying method does not limit the composition of the electrodeless fire-proof and heat-insulating board. For the needs of the examples, the following composition is given

[0019] Group A: 700# high alumina cement 13-16 parts by weight hemihydrate gypsum 10-12 parts by weight 425# ordinary Portland cement 24-27 parts by weight perlite 33-36 parts by weight river sand 14-16 parts by weight cellulose ether 0.15~0.18 parts by weight Water reducer 0.01 part by weight PP fiber 0.1 part by weight Water-cement ratio=0.9:1

[0020] Group B: 700# high alumina cement 13-16 parts by weight hemihydrate gypsum 10-12 parts by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com