Three-dimensional measuring method for complex large object based on stripe period correction

A fringe period and three-dimensional measurement technology, which is applied in the field of measurement, can solve the problems that the period is not a fixed value, affects the measurement result, and measurement error, and achieves the effect of convenient operation and high-precision three-dimensional measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

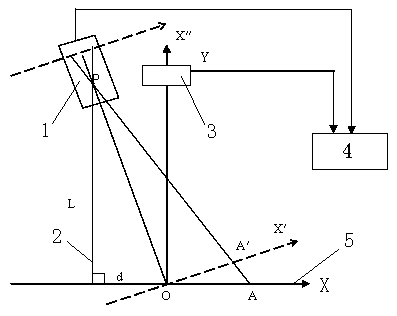

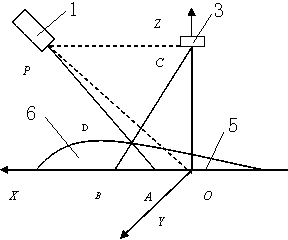

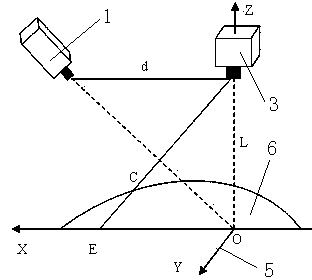

[0025] like figure 1 As shown, the present invention implements and works like this, and its measurement system comprises projector 1, measurement support 2, video camera 3, computer 4, reference plane 5; It is characterized in that: projector 1 and video camera 3 are placed on measurement support 2 Above; the projector 1 and the video camera 3 are respectively connected to the computer 4 with wires, and the computer 4 includes an image acquisition card, projection software, and measurement software; the object 6 to be measured is placed on the reference plane 5 . Projector 1 and camera 3 are at the same height, the optical axis of projector 1 and camera 3 intersect at point O, the distance between them is d, and the distance between them and reference plane 5 is L; P is the light of projector 1 Center, p is the period of the sinusoidal grating fringes on the reference plane 5; X is the x-axis of the reference plane 5, X' is the x-axis of the virtual reference plane 5, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com