Multi-airbag support device for optical element in lithographic projection lens system

A technology for optical elements and lithography projection, which is applied in the direction of optical elements, microlithography exposure equipment, photolithography exposure devices, etc., and can solve the problems of large influence of optical element surface shape and uneven support force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

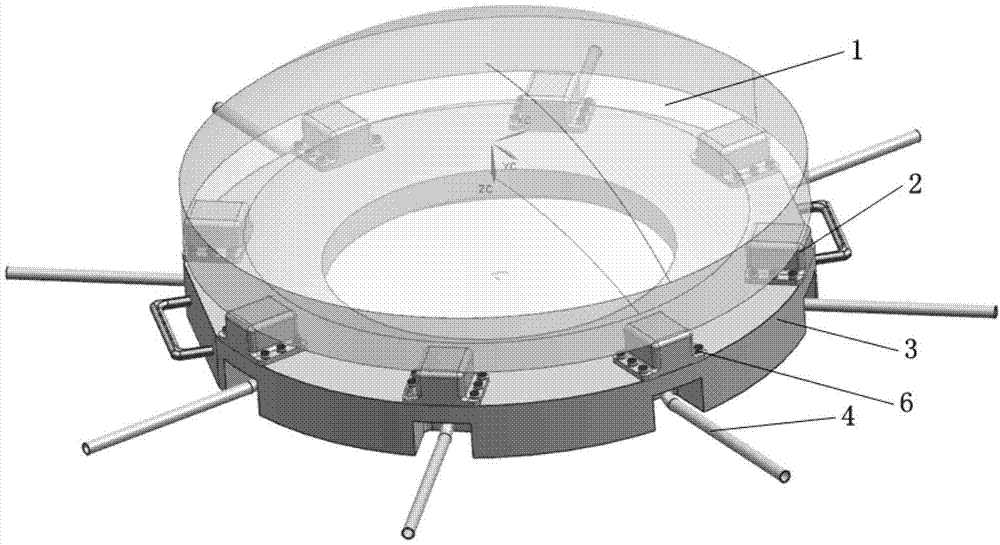

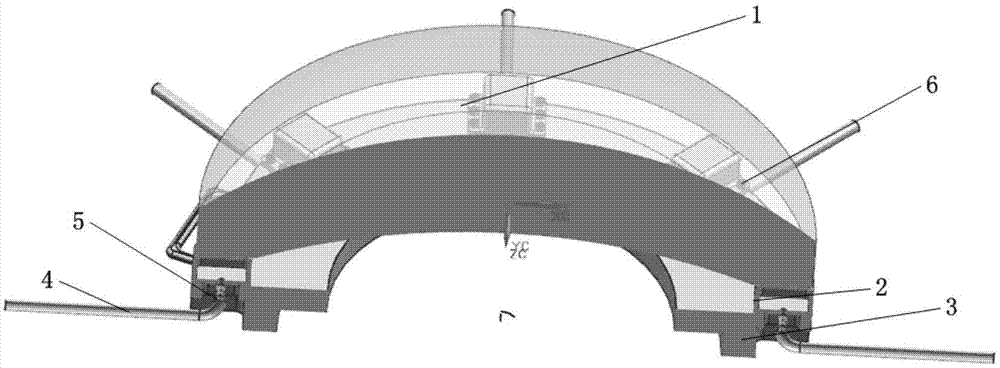

[0019] Such as Figure 1-3 As shown, the optical element multi-airbag support device in the lithography projection objective lens system includes an optical element 1, a plurality of airbags 2, a base 3, an inflatable tube 4 and an adapter 5; the optical element 1 is placed on a plurality of airbags 2; The airbags 2 are evenly distributed along the circumference on the base 3; the airbags 2 are connected with the inflation tube 4 through the adapter 5. The airbag 2 is made of organic rubber material.

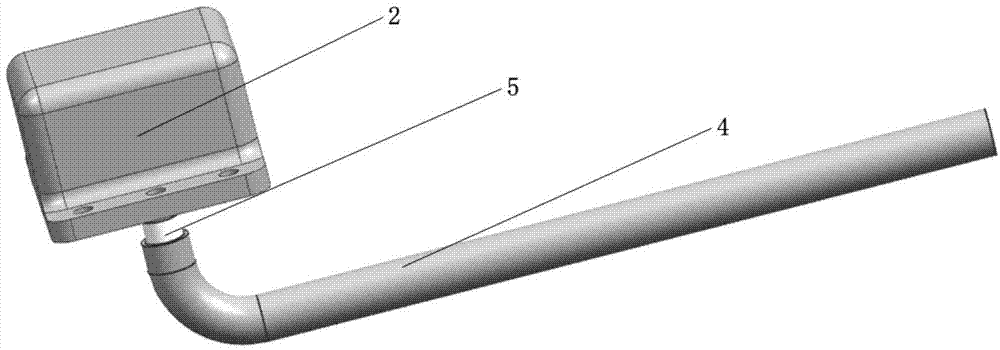

[0020] Such as Figure 4 As shown, the airbag 2 includes an airbag 2-1, and threaded clearance holes 2-2 are provided on both sides of the bottom for fixing. Air intake holes 2-3 are arranged at the bottom for inflation, and each air bag 2 is equipped with an inflation tube 4, and the inflation tube 4 is connected with a valve and an air source. The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com