A carbon fiber precursor wet coagulation bath temperature control process based on immune memory learning control

A technology of carbon fiber precursor and immune memory, applied in the direction of temperature control, adaptive control, general control system, etc., can solve problems affecting the quality of carbon fiber multifilament, uneven quality of precursor fiber, and inability to establish accurate mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

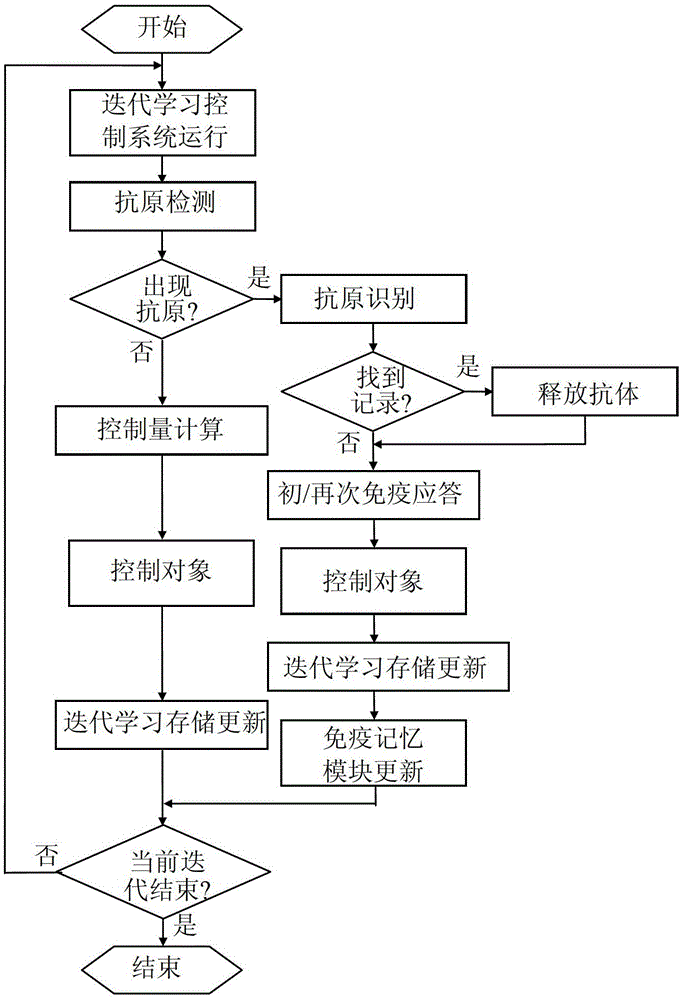

[0155] In this embodiment, random interference is added to the system. The interference amplitude is a random value within ±10% of the control target, and the frequency of interference is 1%. A random interference data such as Figure 4 shown.

[0156] In this embodiment, simulation experiments are carried out on the traditional iterative learning control process and the control process of the present invention at the same time, and the direct results of the two are compared. Wherein, the simulation process of the present invention is simulated according to the specific control process steps in the content of the invention. The control effects of the two comparisons are as follows: Figure 5 shown.

[0157] From Figure 5 and Figure 6 It can be seen from the figure that, compared with the traditional control technology, the control technology of the present invention can better eliminate the error caused by the interference, and further improve the stability of the contro...

Embodiment 2

[0159] In the control process of the coagulation liquid in the coagulation bath, temperature and concentration are two parameters that are controlled at the same time. Therefore, in the process of controlling the temperature of the coagulation liquid, the interference caused by the concentration control process to the temperature parameters must be considered. Since the concentration control is also a repetitive control process, this embodiment simulates the influence of the concentration control on the temperature and adds it as a repetitive disturbance to the temperature control system.

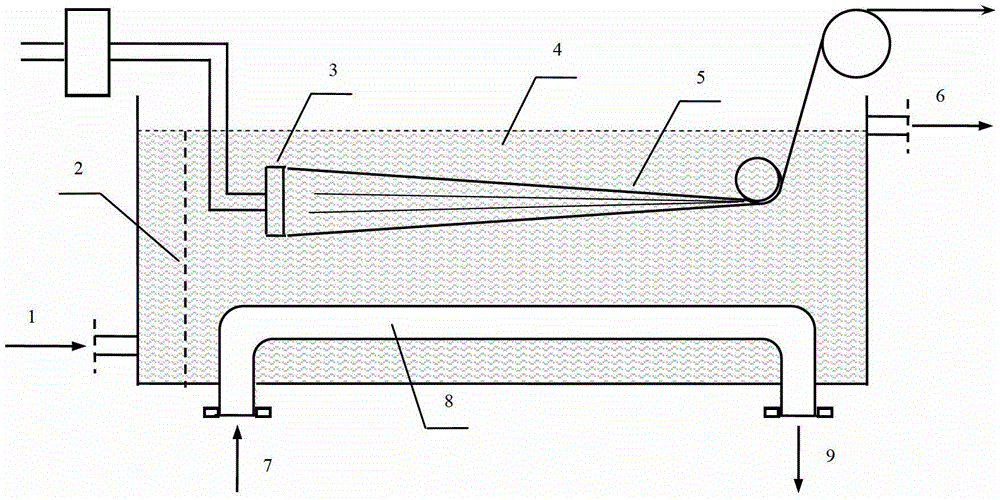

[0160] Concentration control related equipment such as figure 2 As shown, the normal temperature water enters the coagulation bath water tank through the coagulation bath replenishment inlet 1, and the buffer baffle 2 plays the role of easing the fluctuation of the liquid flow. At the same time, in order to ensure the stability of the liquid level, an overflow port 6 is provided at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com