Micro USB (universal serial bus) receptacle

A technology of female seat and PCB board, applied in the direction of base/housing, contact parts, electrical components, etc., can solve the problems of inconvenient processing and manufacturing, high production cost, troublesome assembly, etc., achieve small gap, save materials, and simplify production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

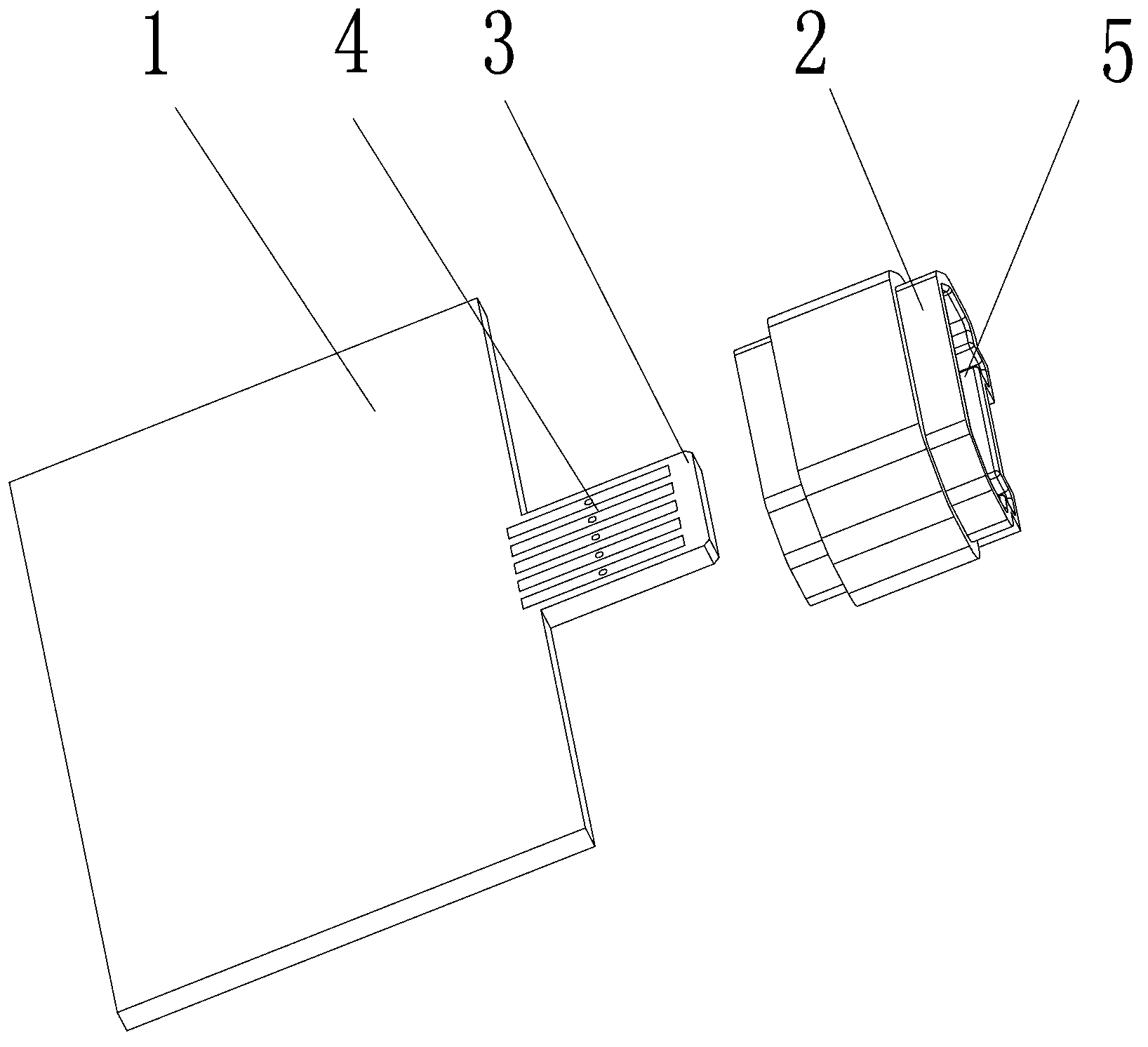

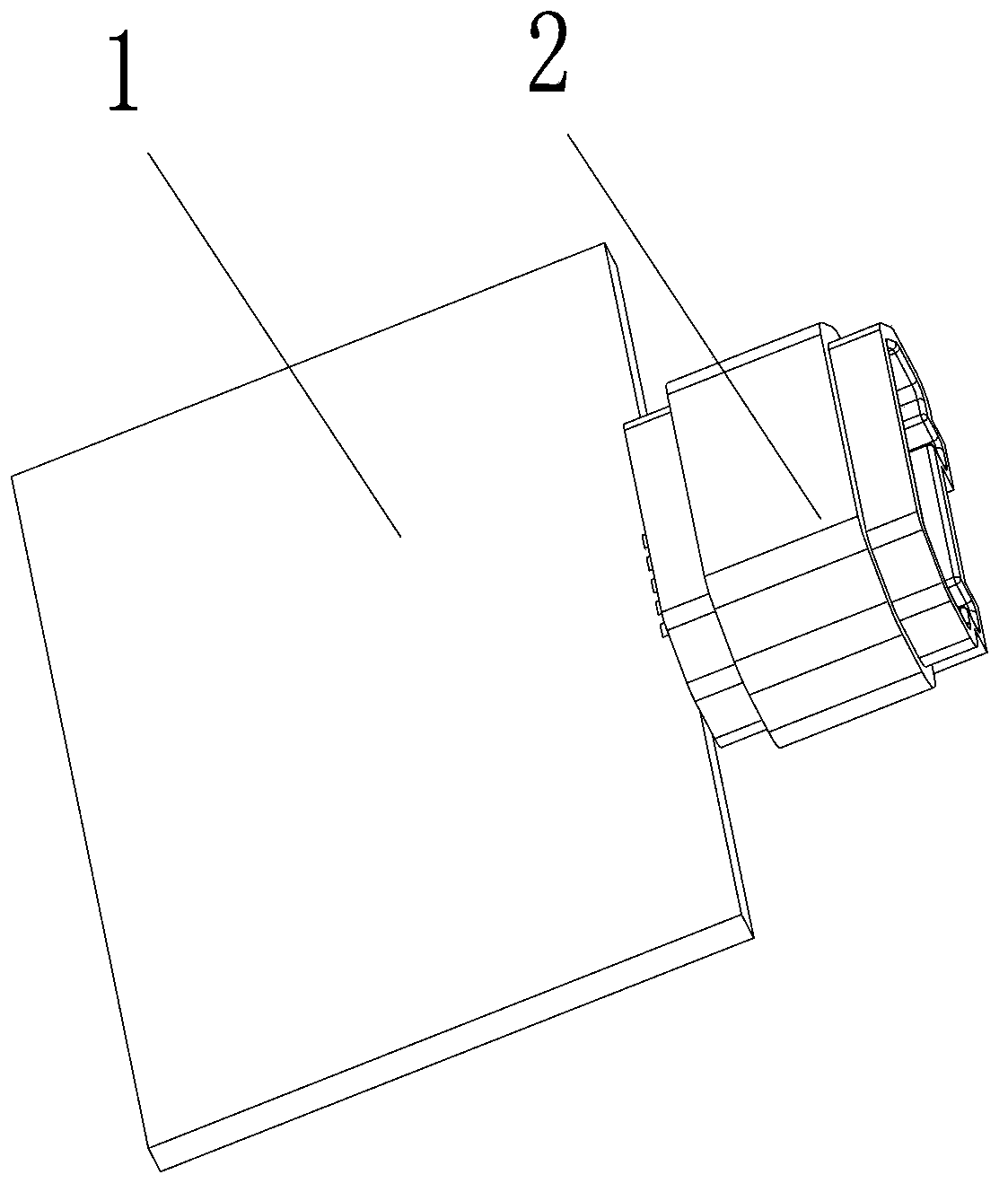

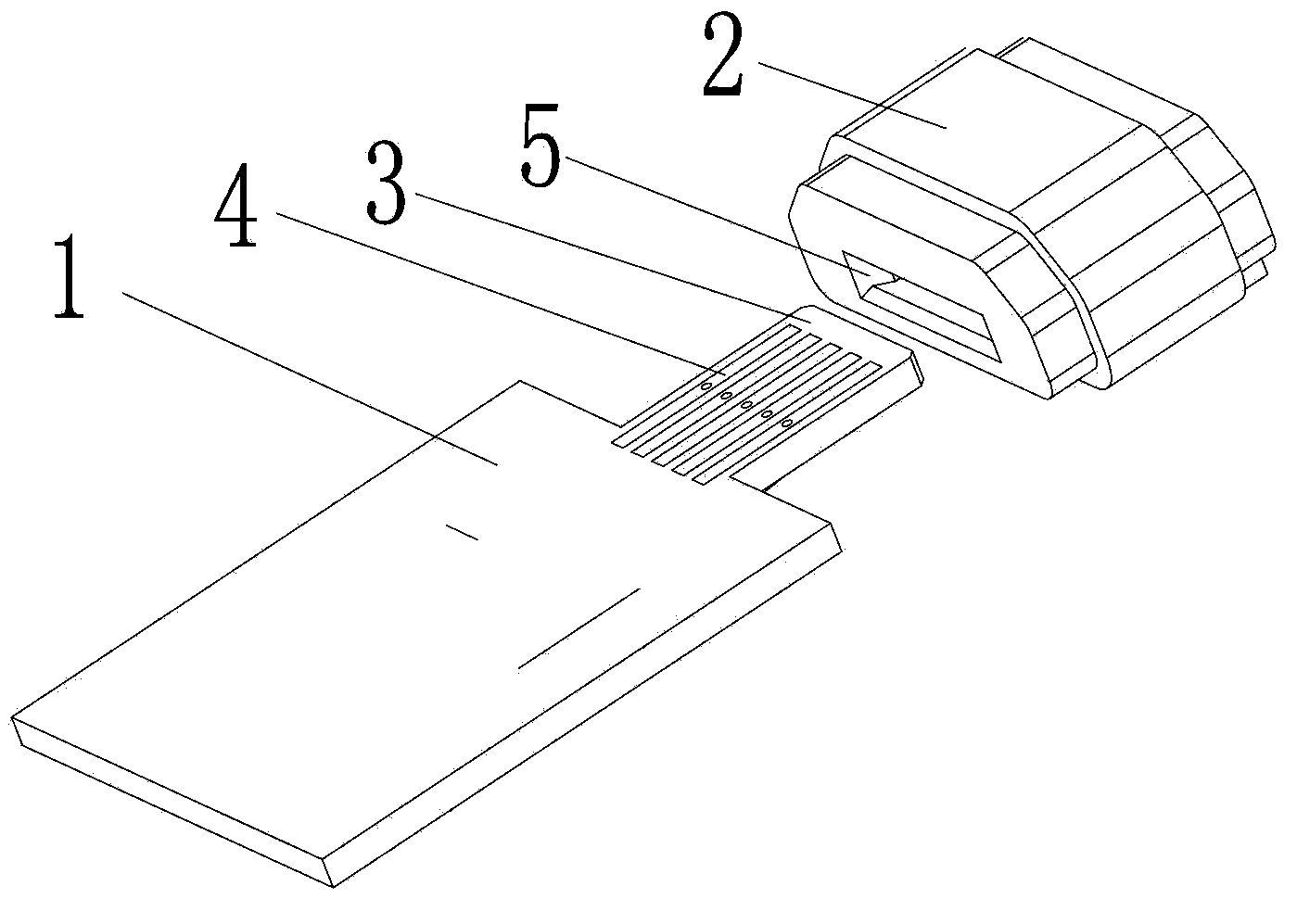

[0016] Such as Figure 1-4 As shown, a Micro USB socket referred to in the present invention includes a PCB board 1 and a housing 2, and a protruding block 3 extends outward from the side of the PCB board 1, and is provided on the surface of the protruding block 3 with a The copper foil 4 connected to the PCB board 1 circuit; the housing 2 is provided with a through hole 5, and the protrusion 3 is inserted into the through hole 5 of the housing 2 to form the connecting core of the USB female seat, and the bottom of the protrusion 3 is provided There is a seal 6 sealing the opening of the through hole 5 .

[0017] In the present invention, the copper foil 4 is composed of multiple wires with energization and communication, and may also have a single energization function, as long as the connecting terminal for connecting the core is formed of copper foil.

[0018] In the present invention, the PCB board 1 and the protruding block 3 are integrated, and the protruding block 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com