Shield with half-cut structure, method and mold for forming same

A shielding and half-cutting technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problem of difficult removal of shielding parts, and achieve the effect of compact structure, high control precision and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will describe in detail in conjunction with embodiments and accompanying drawings.

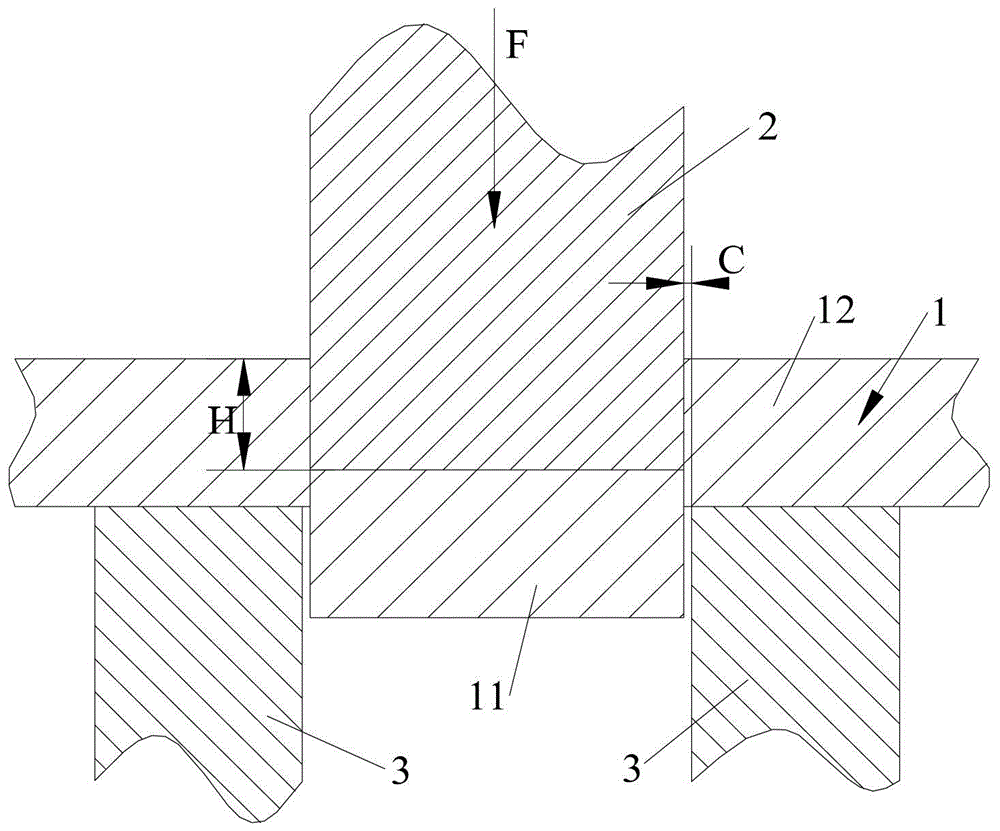

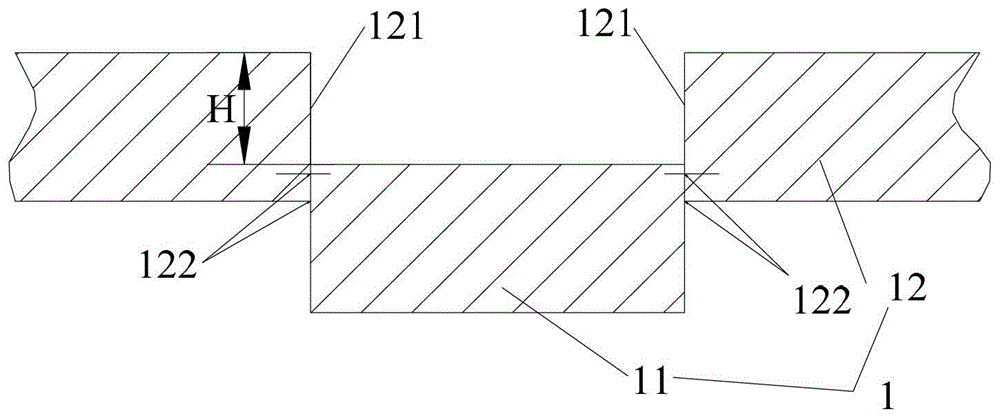

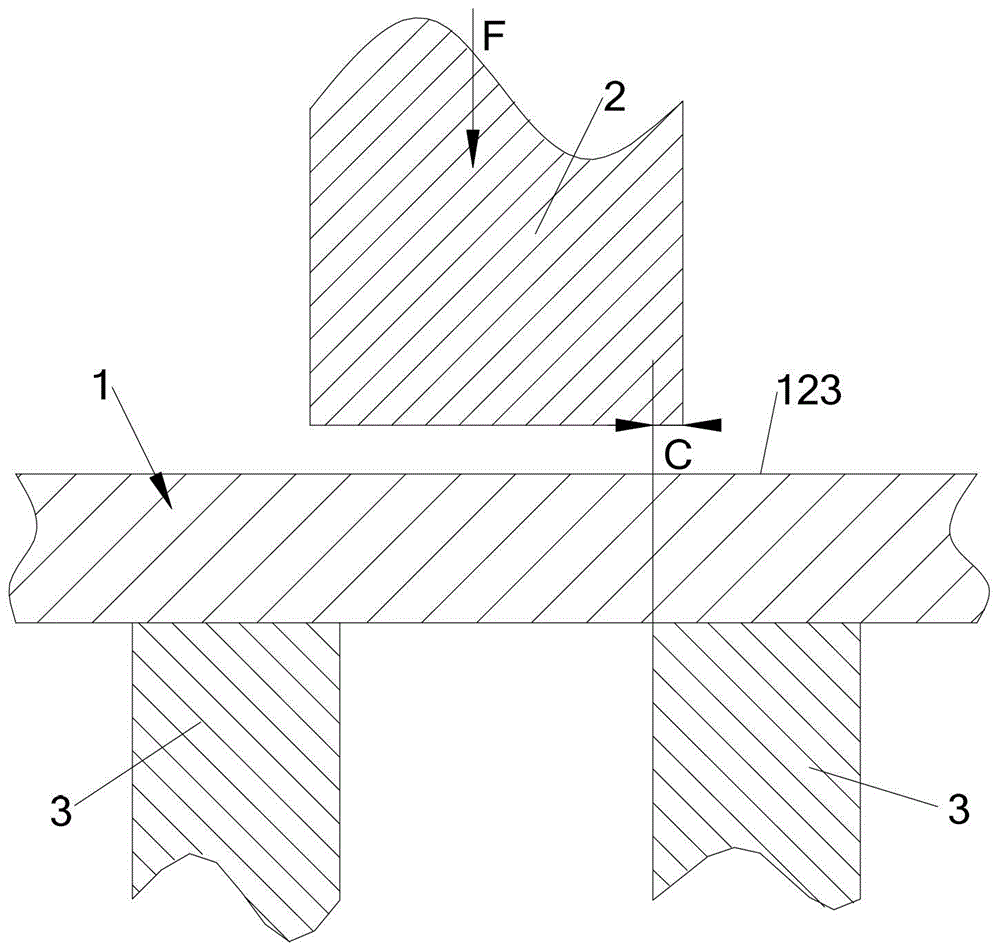

[0028] See Figure 3 to Figure 5 , The method of the present invention for forming the shield 1 with the half-cut structure 11 includes the following steps: A), making the die punch 2 and the cushion block 3 have an interference fit, and the fit interference C is greater than zero; the die punch 2 and the cushion The initial state of block 3 is as image 3 As shown; B), so that the metal part is located between the die punch 2 and the cushion block 3, set the punching depth H of the die punch 2, and the metal part is punched by the die punch 2 to form the half-cut structure 11 , The shield body 12 and the shield 1 of the dense extruded layer 13. The dense extruded layer 13 is connected to the shield body 12 and the half-cut structure 11 by the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| interference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com