Equipment for preparing sulfuric acid

An equipment and technology for sulfuric acid, applied in the field of equipment for preparing sulfuric acid, can solve the problems of large fluctuation, the sulfuric acid needs to be improved, and the sulfuric acid cannot be satisfied, and the effect of low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

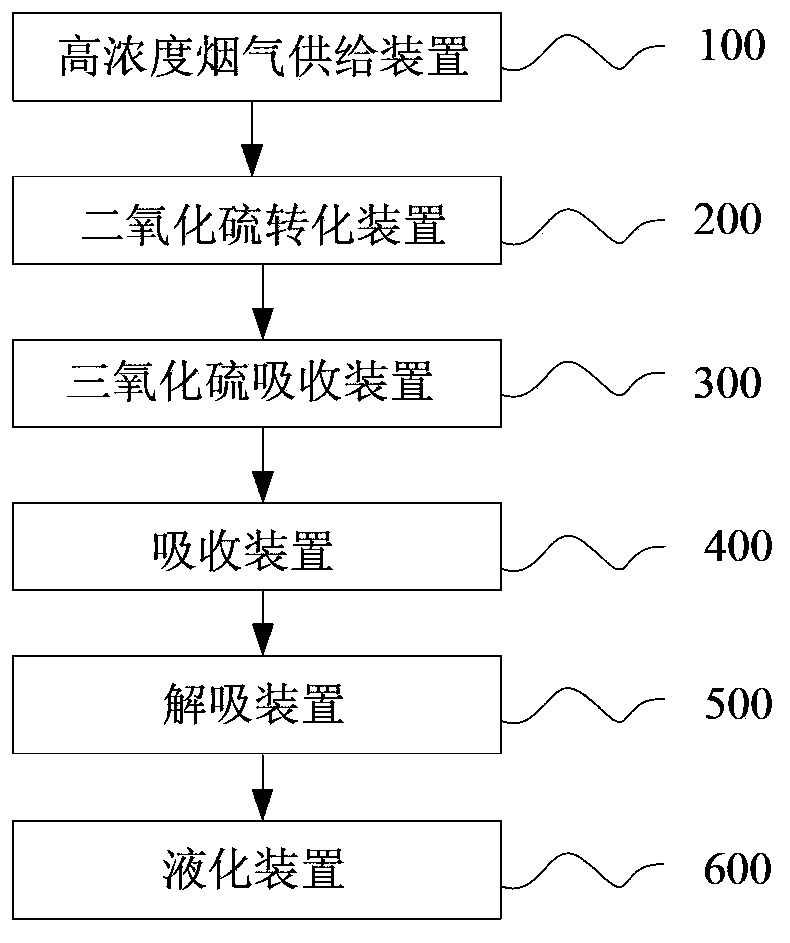

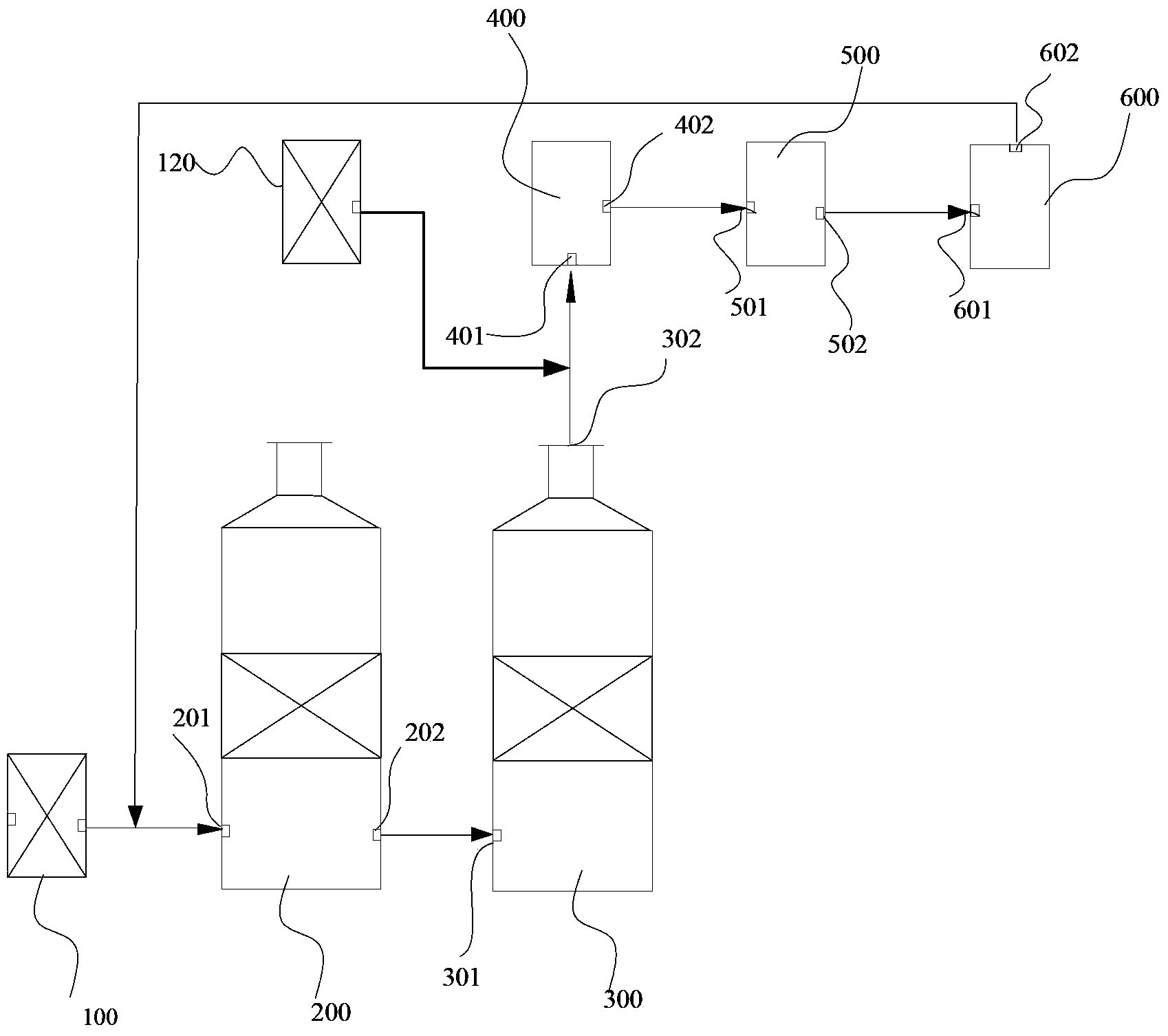

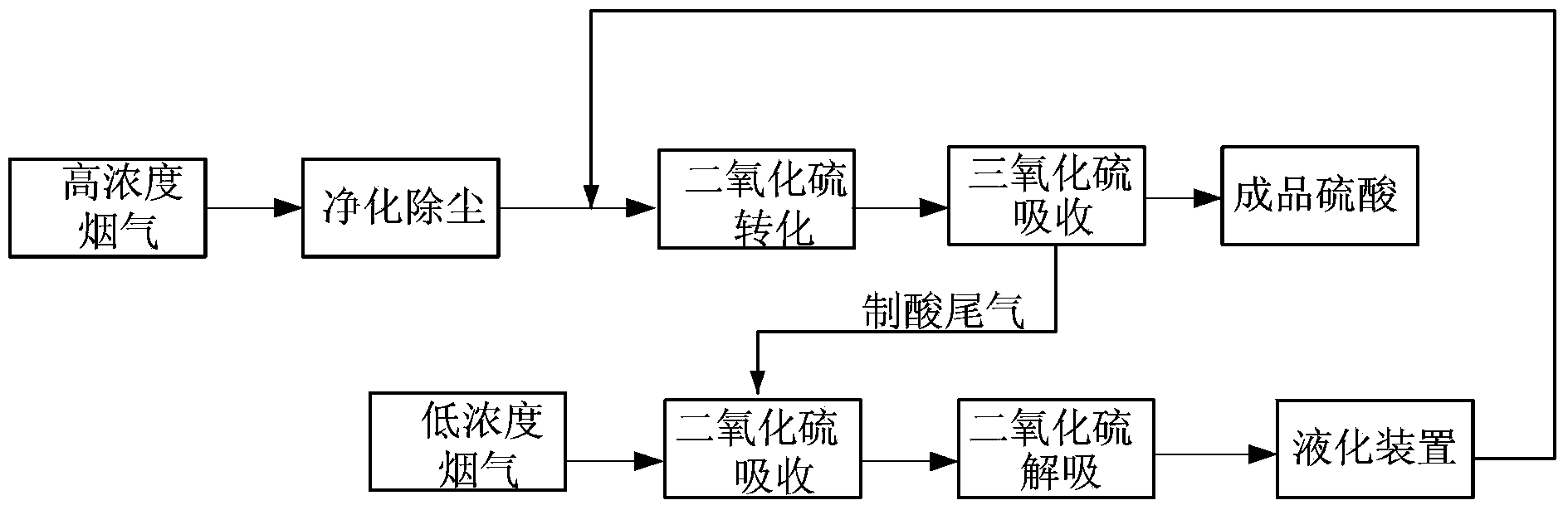

[0070] refer to Figure 4 , the following description adopts the equipment for preparing sulfuric acid of the present invention to prepare sulfuric acid.

[0071] 1. The composition of the high-concentration sulfur dioxide flue gas used to prepare sulfuric acid is as shown in table 1:

[0072] Table 1

[0073]

[0074]

[0075] It can be seen from Table 1 that SO 2 The concentration fluctuates in a large range, specifically, the SO in the oxidation period 2 The highest content can reach 7.65%, and the SO in the slagging period 2 The lowest content is only 0.03%. The content of the oxidation period is 7.65%, and the reduction period is SO 2 The acid system with a content of 3.5% can be produced normally; during the reduction period, diSO 2 The content is 1.07%, SO 2 Content 0.03%. Therefore, the conversion system of acid production cannot be self-thermally balanced, and the normal production of the conversion system needs to be supplemented by heat and other means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com