Radioactive Iodine‑131 Vapor Treatment Unit

A processing device and a technology of radioactive iodine, which are applied in the field of radioactive iodine-131 vapor processing devices, can solve the problems of large effective operation space, large radiation dose for staff, lack of adsorption effect of activated carbon column, etc., and achieve the effect of safe processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

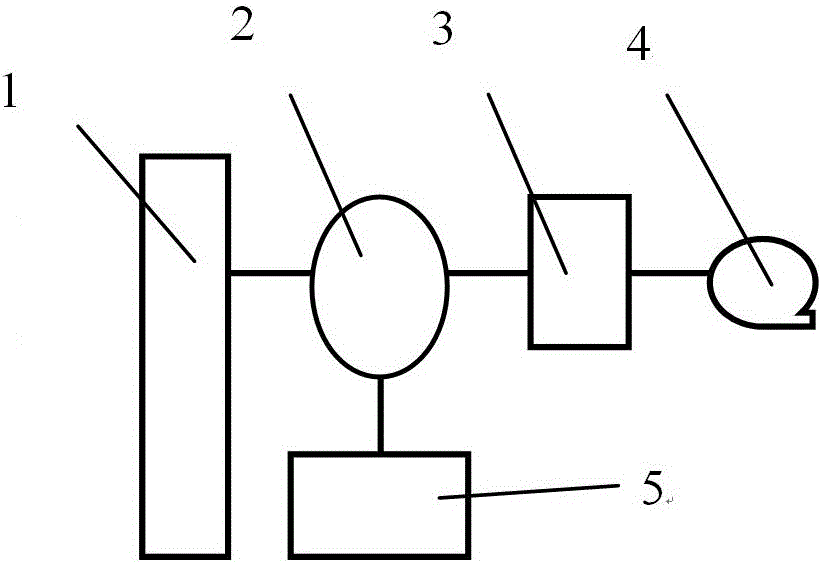

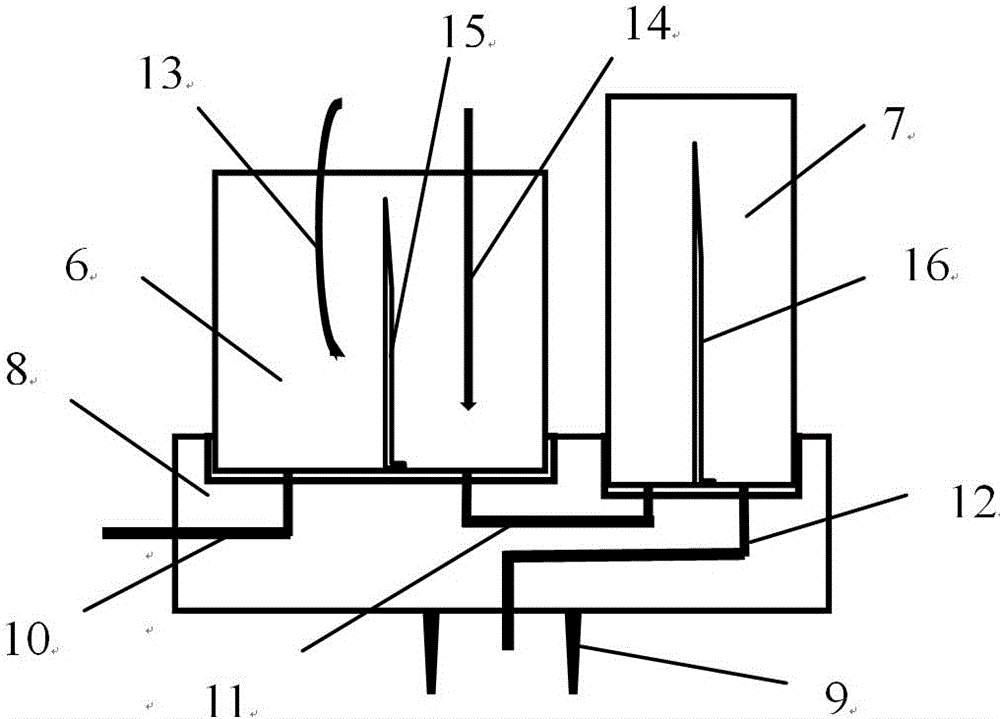

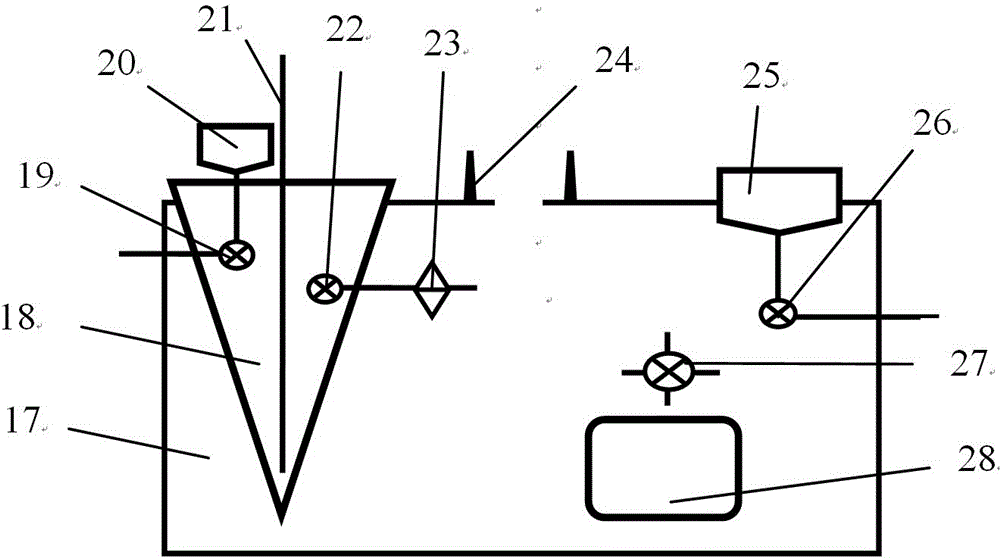

[0024] figure 1 It is a structural block diagram of the radioactive iodine-131 vapor treatment device of the present invention, figure 2 is a schematic structural view of the adsorption device in the present invention, image 3 is a schematic structural view of the alkali absorption device in the present invention, Figure 4 It is a structural schematic diagram of the exhaust gas monitor in the present invention. exist Figure 1~Figure 4 Among them, the radioactive iodine-131 vapor treatment device of the present invention includes an alkali absorption device 1, an adsorption device 2, an exhaust gas monitor 3, a vacuum pump 4, and a temperature controller 5. The connection relationship is that the alkali absorption device 1 is placed in The bottom of the adsorption device 2 is threadedly connected with the adsorption device 2 , the adsorption device 2 , exhaust gas monitor 3 , and vacuum pump 4 are sequentially connected through pipelines, and the adsorption device 2 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com