Material mixing apparatus with folded plate type deflection baffles

A technology of baffles and mixers, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., which can solve the problem of affecting the full shape and color of particles, abrasion and scratches of polyester particles, and easy jamming at the bottom and other problems, to achieve the effect of reducing damage, realizing automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

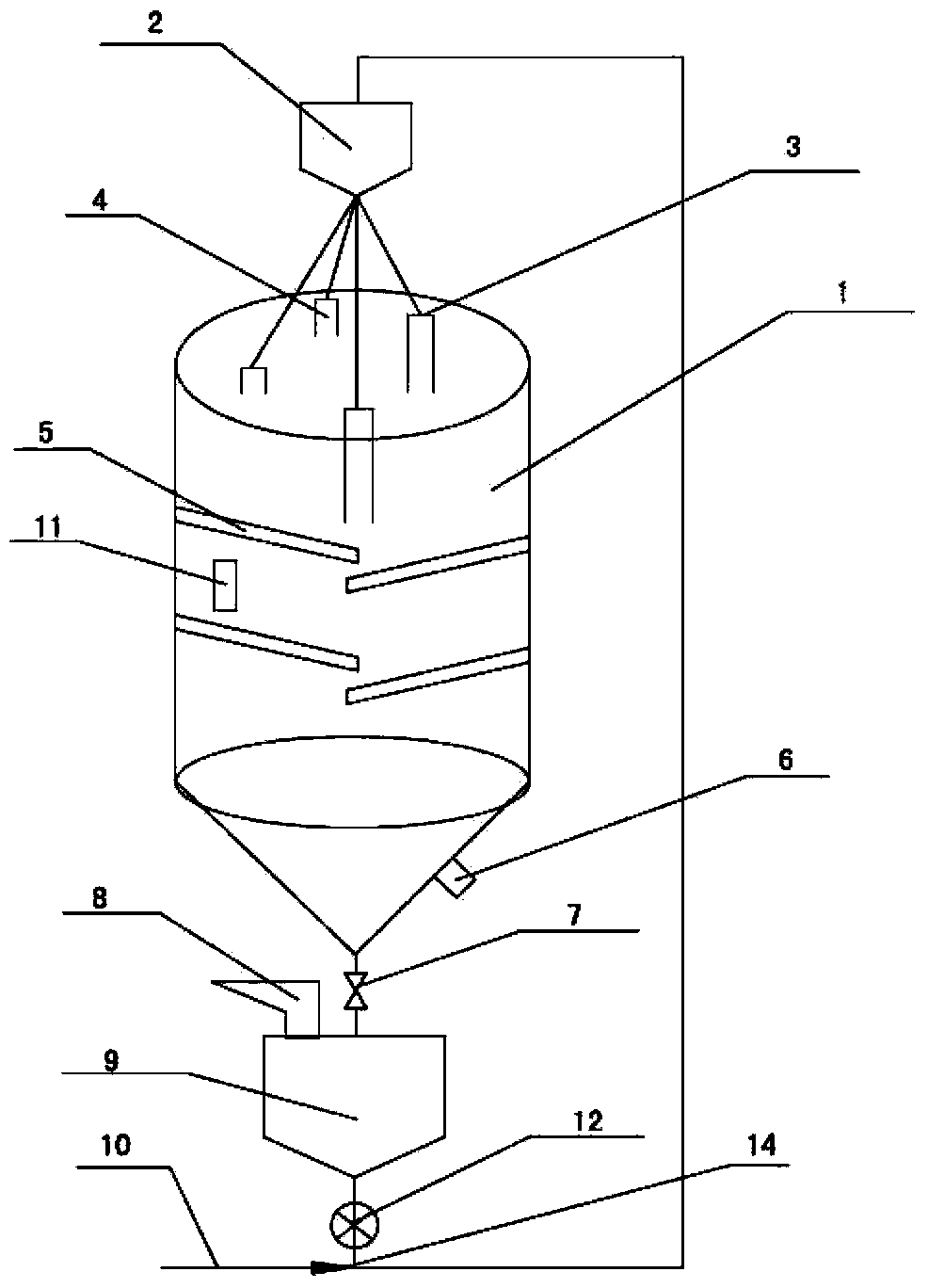

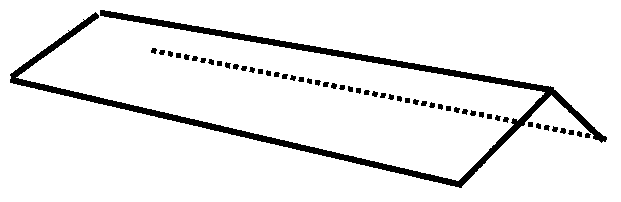

[0037] like figure 1 As shown, the present invention includes a cylindrical mixing barrel 1, and the inside of the cylindrical mixing barrel 1 is provided with a folded-plate baffle baffle 5, and the folded-plate baffle 5 is inclined downward. The structural representation of the folded-plate type baffle plate 5, such as image 3 .

[0038] Based on the connection line between one end of the flap-type baffle 5 and the wall of the mixing tube, the other end of the flap-type baffle 5 is inclined downward at an angle of 30°, and the length must cross the center line. The included angle of the flow baffle 5 is 120°.

[0039] Folded plate baffles 5 are staggered in height and evenly distributed in cylindrical mixing barrel 1, such as Figure 4 .

[0040] The height is staggered and evenly distributed: the folded-plate baffles 5 are longitudinally divided into 4 rows, and the four adjacent folded-plate baffles 5 form a working unit from top to bottom. Among them, in the first wo...

Embodiment 2

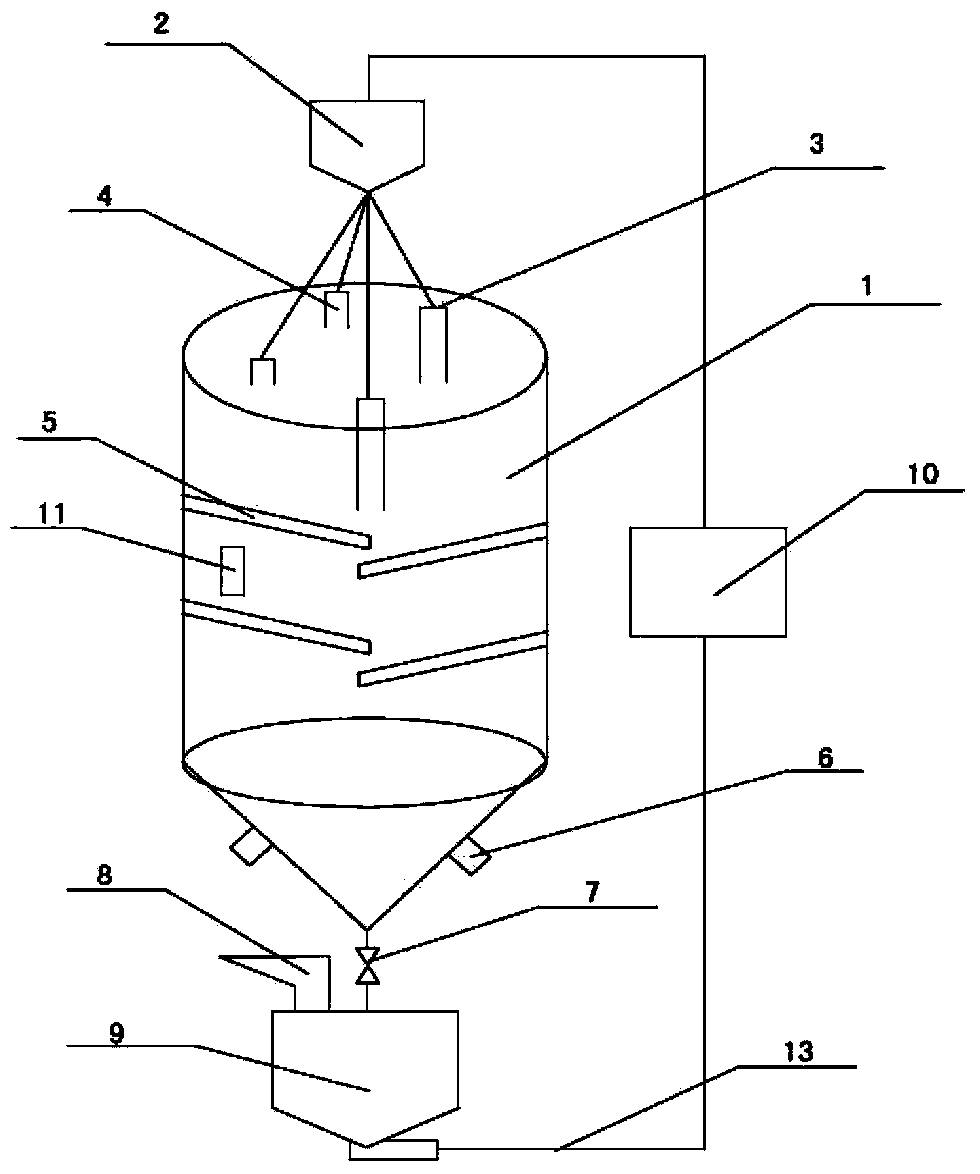

[0046] like figure 2 As shown, the present invention includes a cylindrical mixing barrel 1, and the inside of the cylindrical mixing barrel 1 is provided with a folded-plate baffle baffle 5, and the folded-plate baffle 5 is inclined downward. The structural representation of the folded-plate type baffle plate 5, such as image 3 .

[0047] Based on the connecting line between one end of the flap-type baffle 5 and the wall of the mixing tube, the other end of the flap-type baffle 5 is inclined downward at an angle of 35°, and the length must cross the center line. The included angle of the flow baffle 5 is 150°.

[0048] Folded plate baffles 5 are spirally evenly distributed in the cylindrical mixing barrel 1 with the centerline of the cylindrical mixing barrel 1 as the reference, such as Figure 5 .

[0049] Folded-plate baffle 5 rotates clockwise by 45° sequentially.

[0050] A first buffer tank 2 is arranged above the cylindrical mixing barrel 1, a feed inlet 3 is arr...

Embodiment 3

[0055] Based on the connecting line between one end of the flap-type baffle 5 and the wall of the mixing tube, the other end of the flap-type baffle 5 is inclined downward at an angle of 15°, and the length must cross the center line. The included angle of the flow baffle 5 is 130°. Folded-plate type baffle 5 is adjacent to the upper and lower two-layer spacing distance of 30cm, and others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com