Preparation method and application of nanometer tubular cuprous bromide photocatalysis material

A photocatalytic material, cuprous bromide technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve photochemical corrosion and photocatalytic effects Ideal, low quantum yield, etc., to achieve the effect of mild conditions, simple preparation process, and cheap and easy-to-obtain raw materials

Inactive Publication Date: 2015-05-06

山西师范大学

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although these works are effective, their quantum yield is not high, and it is difficult to be used for photocatalytic cracking of water to produce hydrogen. Therefore, finding new high-efficiency photocatalysts has become one of the most important topics in this field.

According to the photocatalytic materials that have been discovered, the system can be divided into oxides, sulfides, oxysulfides, nitrides and oxynitrides, among which oxides often have better (photo) chemical stability; sulfides and oxysulfides Although compounds can show relatively ideal visible light response characteristics, they are prone to photochemical corrosion as photocatalytic materials; nitrides and oxynitrides also have good visible light absorption characteristics, and their photocatalytic effects are not ideal.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

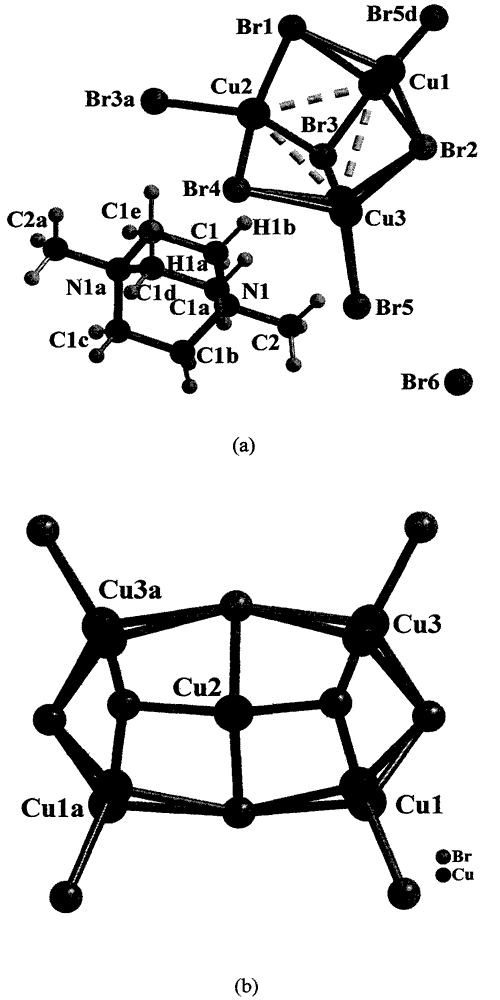

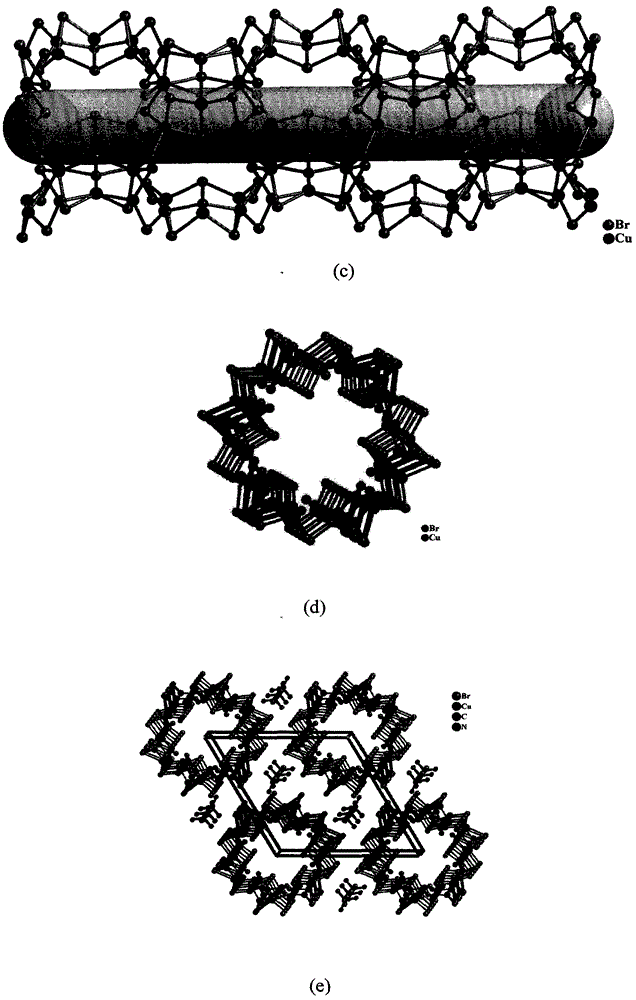

The invention discloses a preparation method and application of a nanometer tubular cuprous bromide photocatalysis material. The method comprises the following steps: dissolving the mixture of CuBr2 and triethylene diamine into a methanol solution of which the volume ratio of methanol to water is 4 to 2, and stirring by a magnetic force stirrer, wherein the molar ratio of CuBr2 to triethylene diamine is 5 to 3; dropwise adding perchloric acid in the stirring process to adjust the pH value of the solution; after 30 minutes, transferring the mixed solution to a reaction kettle provided with a polyfluortetraethylene substrate, keeping heating for 96 hours in a baking oven at 100 DEG C; cooling to indoor temperature at a speed of 5 DEG C per hour; filtering and water washing to obtain the product. According to the invention, nano-particles can be obtained through one-step reaction, so that grain coarsening and gathering in the high-temperature sintering are avoided; besides, raw materials are low in cost and easy to obtain, the manufacturing technology is simple to operate and requires mild condition; moreover, the crystallinity and phase composition of the product can be controlled easily as parameters in the reaction are adjustable.

Description

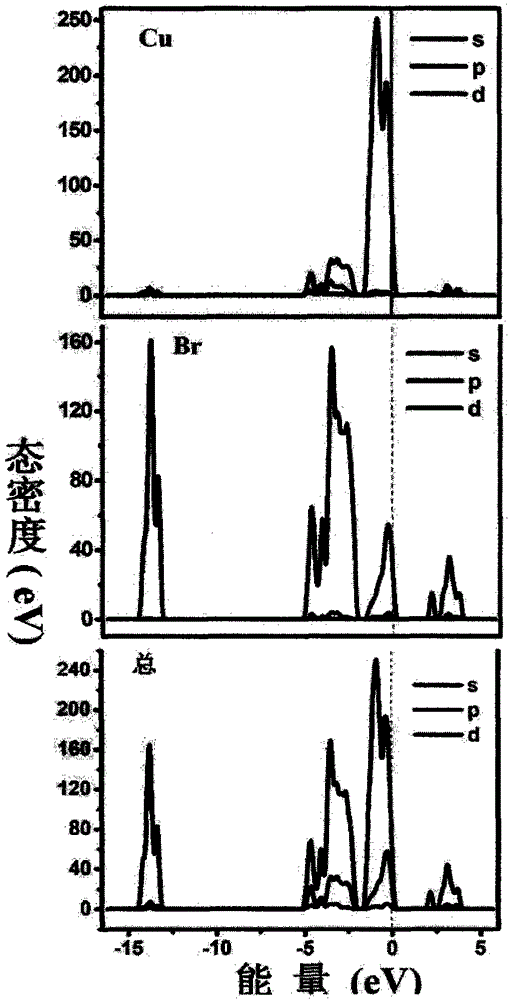

technical field [0001] The invention relates to a preparation method and application of a nanotube cuprous bromide photocatalytic material, which belongs to the technical field of functional materials. Background technique [0002] Since 1972 Fujishima and Honda discovered in TiO 2 Since the phenomenon of photoresponsive hydrogen production on the surface of electrode materials (Fujishima, A. Honda, K., Nature 238, 37-38), photocatalysis has attracted worldwide attention as a potential technology to solve environmental pollution and energy crisis. In the process of semiconductor photocatalysis, light irradiation excites electrons in the valence band to transition to the conduction band, forming photogenerated electrons on the conduction band and photogenerated holes on the valence band; after the carriers migrate to the surface of the powder particles, they are fully integrated with the surrounding Environmental effects, complex oxidation and reduction reactions occur. [...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J31/16C02F1/32

Inventor 张献明姚如心

Owner 山西师范大学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com