Stamping stroke measuring mechanism used on stamping machine

A technology of stamping stroke and measuring mechanism, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting production efficiency and low precision, and achieve the effect of improving production efficiency, improving precision and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

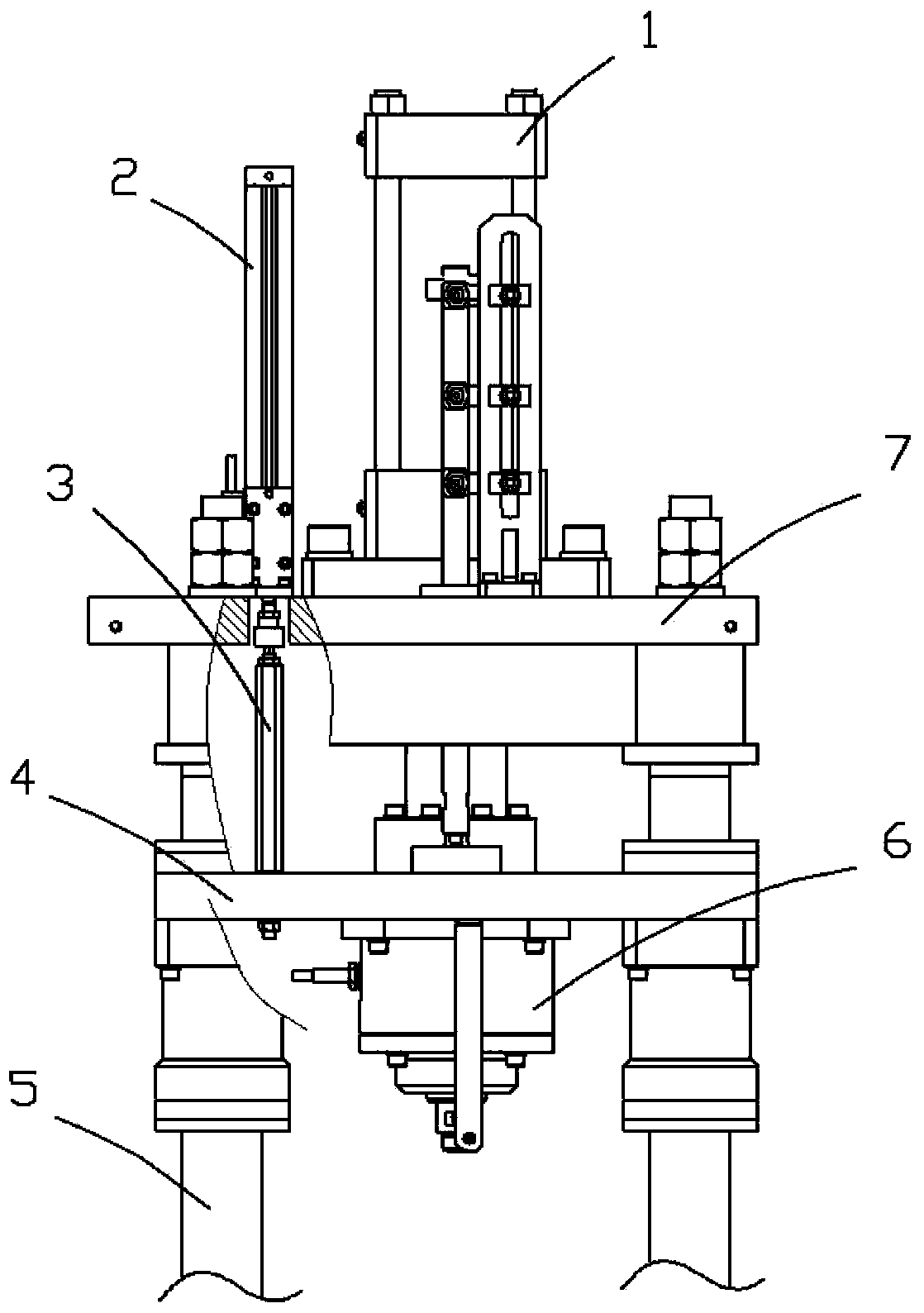

[0013] Such as figure 1 Shown is an embodiment of a stamping stroke measuring mechanism used on a stamping machine of the present invention, which includes a top plate 7 arranged on the top of the frame and a moving plate 4 that can move up and down on the frame. Head 6, the grating sensing sleeve 2 is installed on the top plate 7, one end of the moving sensing part 3 is fixed on the moving plate 4, and the other end is inserted into the grating sensing sleeve 2.

[0014] The grating sensing sleeve 2 is electrically connected to a display device.

[0015] A hydraulic cylinder 1 is installed on the top plate 7 , and the piston rod of the hydraulic cylinder 1 passes through the top plate 7 and is fixed on the moving plate 4 .

[0016] The moving plate 4 is movably installed on the guide co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap