Clamping tool for machining eccentric shafts

A technology for clamping tooling and eccentric shafts, which is applied in metal processing equipment, metal processing machine parts, clamping, etc., can solve the problems of low productivity and inability to meet the needs of parts processing, and achieve low manufacturing cost, convenient maintenance, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

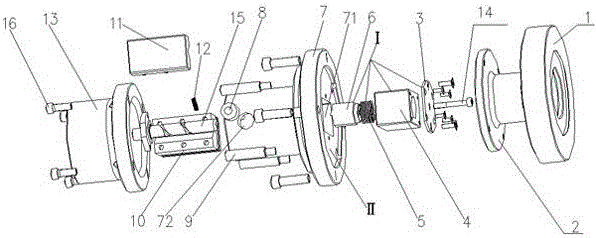

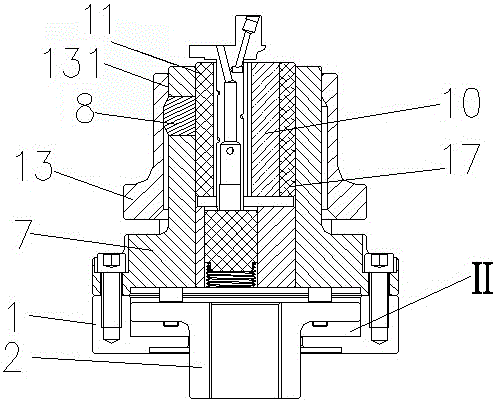

[0019] see Figure 1 to Figure 3 , the clamping tool for processing eccentric shafts according to the present invention includes a connecting plate 1, a tensioning plate 2, a fixing plate 3, a positioning sleeve 4, a spring 5, a positioning block 6, a mold shell 7, a pressing column 8, a tensioning Rod 9, V-shaped block 10, pressing plate 11, pressing plate spring 12 and pressing sleeve 13, described connecting plate 1, tensioning plate 2, formwork 7 and pressing sleeve 13 are installed coaxially successively.

[0020] The positioning sleeve 4 is provided with a through cavity, the positioning block 6, the spring 5, the positioning sleeve 4, and the fixing plate 3 are assembled and installed in sequence, the spring 5 is arranged in the cavity of the positioning sleeve 4, and one end of the spring 5 is against the fixing plate 3. The other end is against the positioning block 6, the positioning sleeve 4 is fixedly connected with the fixing plate 3, the bolt 14 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com