Novel efficient notch airfoil shape of parafoil unmanned plane and optimum design method thereof

A notch and airfoil technology, applied in the field of parafoil UAV, can solve the problems of unfavorable lift-to-drag ratio, uneven aerodynamic load distribution, separation of the upper surface of the parafoil, etc., to achieve stable control of the angle of attack range and improve the efficiency of pitch control , the effect of large control angle of attack range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

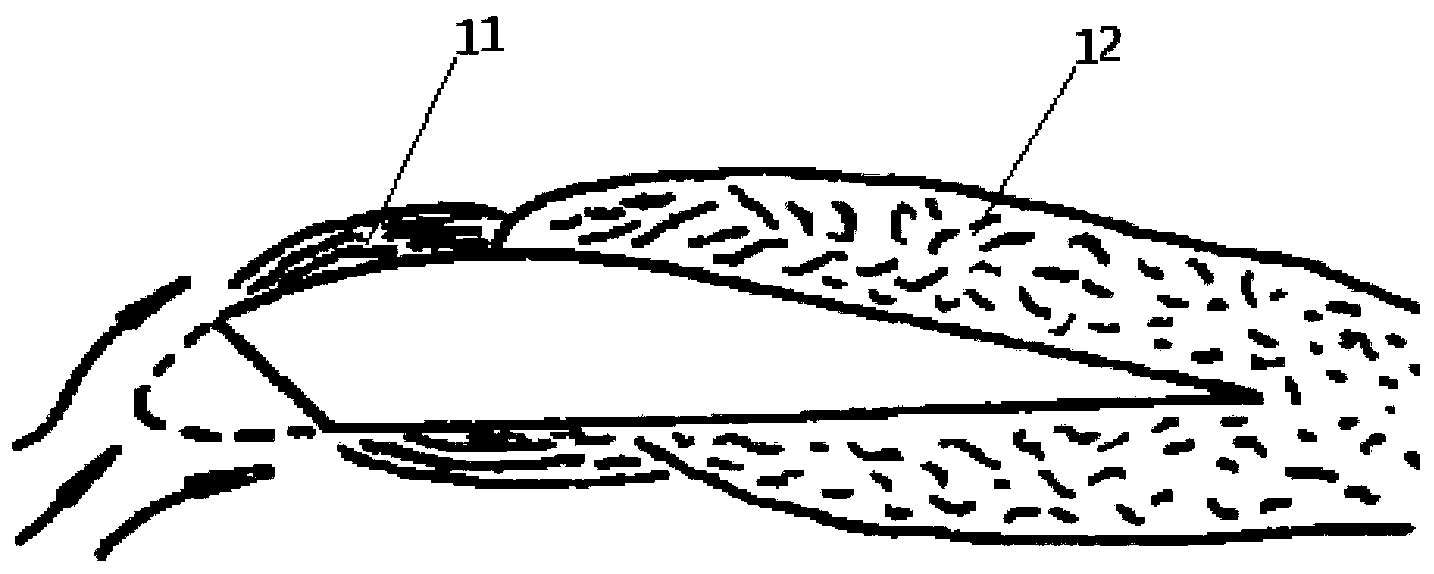

[0042] as attached Image 6 As shown, the slit airfoil of the present invention is connected to the fuselage of the drone through the parachute rope 2, and is connected to the steering gear on the fuselage through the trailing edge control rope 3. When inflated, the airflow enters and exits the air chamber 5 of the parafoil through the cutout 1 at the leading edge, so that the canopy 4 takes on an airfoil shape and maintains the inflation stiffness. Manipulate the rope to realize the control of α.

Embodiment 2

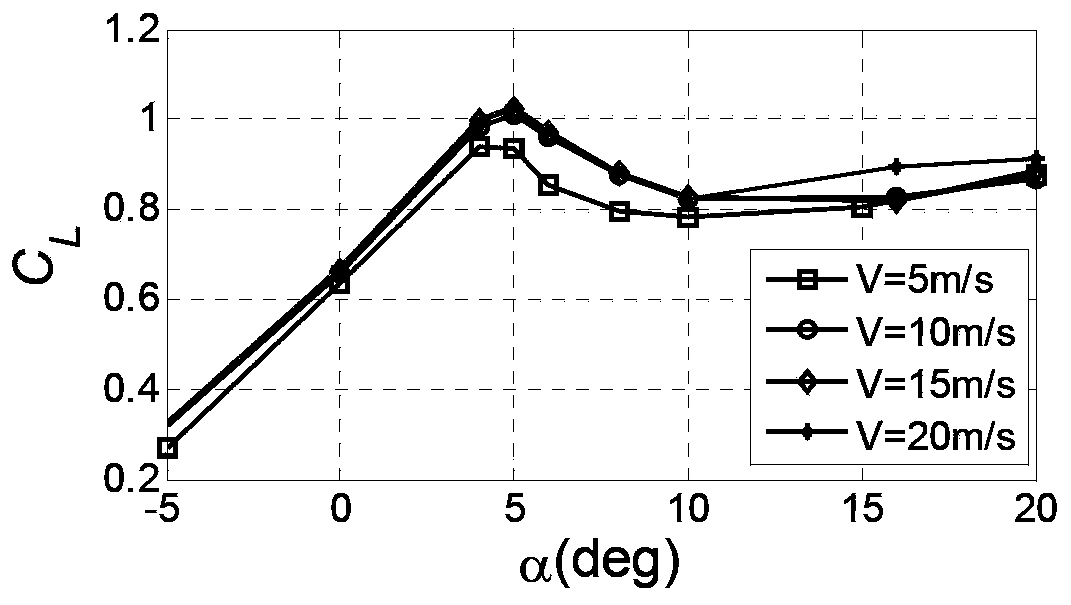

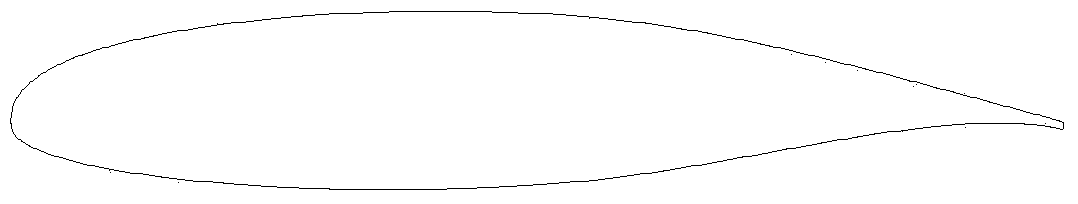

[0044] The CFD method is used to analyze the aerodynamic characteristics of the slit airfoil of the present invention after inflation. When the Reynolds number Re=0.66e+06, the lift characteristics and the lift-to-drag ratio characteristics are shown in the appendix Figure 7 , when the installation angle α=6°-8°, it has the maximum lift-to-drag ratio, and the present invention has a stable pitch control range within the installation angle α=0°-12°. Among them, when the installation angle α=6°, the flow characteristics are shown in the attached Figure 8 , the pressure distribution of the notched airfoil see the attached Figure 9 .

[0045] Among them, the Reynolds number Re is the ratio of the fluid inertial force to the viscous force, ρVl / μ, where V is the flow velocity, l is the length of the flowing object, ρ is the density, and μ is the fluid viscosity coefficient. The characteristics of the airfoil are greatly affected by the Reynolds number during its motion, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com