Manufacturing method oflaser fluorescent anti-fake tear tape with both sides in gold or silver stamping

A front and back double-sided, anti-counterfeiting pulling wire technology, applied in the direction of flexible covering, packaging, wrapping paper, etc., can solve the problem of no high-tech content and anti-counterfeiting performance, can not compound the front and back sides of BOPP film, to achieve strong anti-counterfeiting performance, Beautifully designed, complex structure and craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

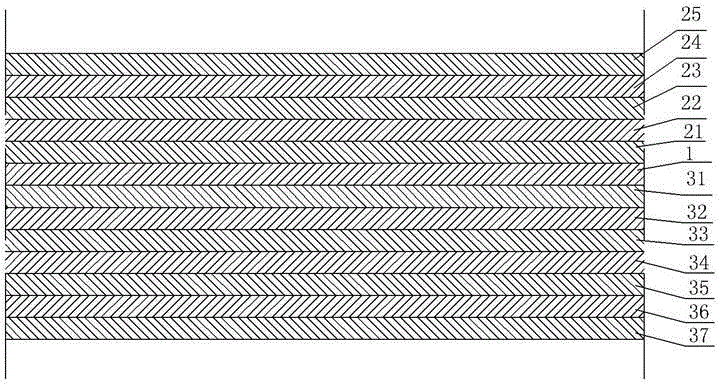

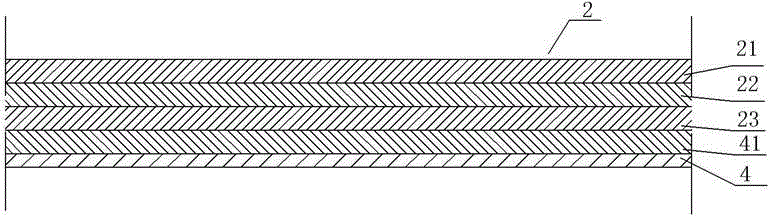

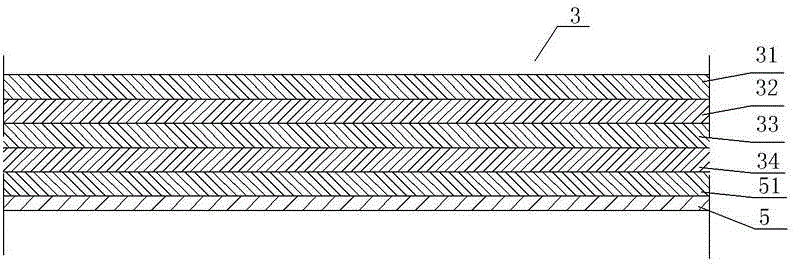

[0019] like figure 1 As shown, the present invention is a gold and silver laser fluorescent anti-counterfeiting pull wire with double-sided hot stamping on the front and back, and its structure includes a polyethylene film 1, a golden surface layer 2 compounded on the front side of the polyethylene film 1 and a laser compounded on the back side of the polyethylene film 1. Fluorescent surface layer 3, wherein the golden surface layer 2 includes a front hot stamping adhesive layer 21, a front aluminum plating layer 22, a yellow line ink layer 23, a front varnish protective layer 24, and a pressure-sensitive glue layer 25 arranged sequentially from the inside to the outside; The laser fluorescent surface layer 3 includes a reverse hot stamping adhesive layer 31, a red fluorescent layer 32, a laser film lamination layer 33, a reverse aluminum layer 34, a transparent text layer 35, a reverse varnish text protection layer 36, and silicone oil arranged in sequence from the inside to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com