Method for preparing alkali earth metal stannate

An alkaline earth metal and stannate technology, which is applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of low SnO2 conversion rate, complicated alkaline earth metal stannate process, and restricting the popularization and application of process methods. The effect of shortened roasting time, short roasting time and high tin conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

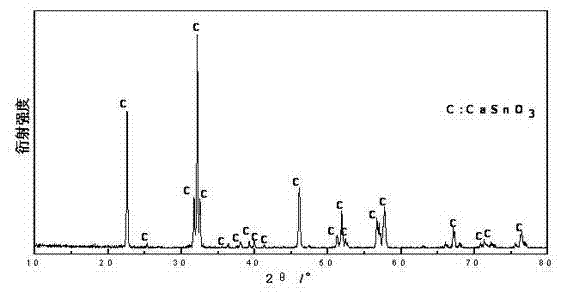

[0032] Use tin dioxide and calcium carbonate with a purity of 99.5% as raw materials, grind them until the mass percentage of -0.074mm particle size is not less than 80%, and then mix the two evenly according to the Sn:Ca molar ratio of 1: 1; dry the mixture After that, put it into the roaster under CO / CO 2 Atmosphere heating and roasting, the roasting temperature is 600°C, the roasting time is 120min, the volume concentration of CO [CO / (CO+CO 2 )] is 5%; the roasted product is cooled and taken out to obtain calcium stannate (CaSnO 3 ). The calculated conversion rate of tin is 98.9%.

[0033] The XRD result of the prepared product under this condition is as attached figure 1 shown. From attached figure 1 It can be seen that the substance corresponding to all the diffraction peaks is calcium stannate (CaSnO 3 ), indicating that the purity of calcium stannate in the obtained product is high. figure 1 No diffraction peaks were found for other impurities.

Embodiment 2

[0035] Use tin dioxide and calcium oxide with a purity of 99.5% as raw materials, grind them separately until the mass percentage of -0.074mm particle size is not less than 80%, and then mix the two evenly according to the Sn:Ca molar ratio of 1: 1.09; dry the mixture After that, put it into the roaster under CO / CO 2 Atmosphere heating and roasting, the roasting temperature is 800°C, the roasting time is 60min, the volume concentration of CO [CO / (CO+CO 2 )] is 15%; the roasted product is cooled and taken out to obtain calcium stannate (CaSnO 3 ). The conversion rate of tin was 99.1%.

Embodiment 3

[0037] Use tin dioxide and calcium carbonate with a purity of 99.5% as raw materials, grind them separately until the mass percentage of -0.074mm particle size is not less than 80%, and then mix the two evenly according to the Sn:Ca molar ratio of 1: 1.2; dry the mixture After that, put it into the roaster under CO / CO 2 Atmosphere heating and roasting, the roasting temperature is 1200°C, the roasting time is 10min, the volume concentration of CO [CO / (CO+CO 2 )] is 20%; the roasted product is cooled and taken out to obtain calcium stannate (CaSnO 3 ). The conversion rate of tin was 99.2%.

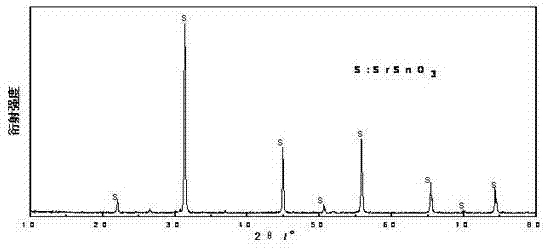

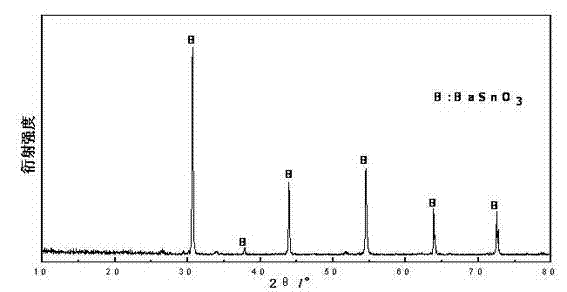

[0038] (2) Preparation of strontium stannate:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com