A kind of preparation method of environment-friendly formaldehyde-free wood special-purpose furan resin adhesive

An adhesive and resin-like technology, applied in adhesives, organic chemistry, etc., can solve the problems of pollution and formaldehyde, and achieve the effects of solving formaldehyde pollution, good water resistance, and good fire and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

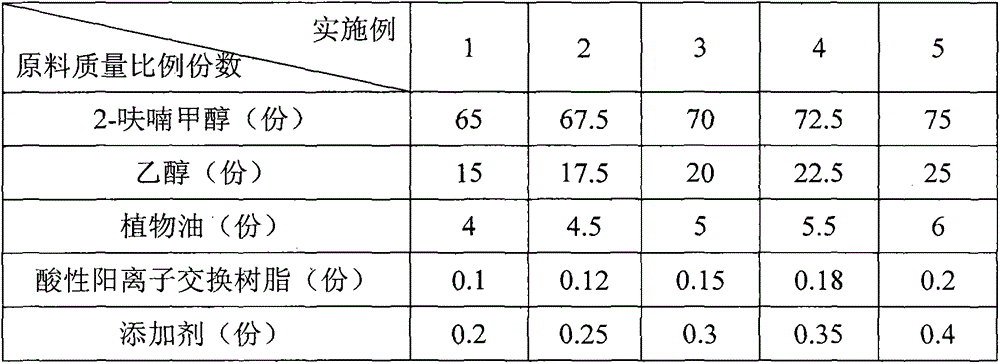

[0012] A method for preparing an environment-friendly formaldehyde-free furan resin adhesive for wood. Firstly, 2-furan methanol is prepared, and then the resin adhesive is prepared by using 2-furan methanol. The key is: the 2-furan methanol is obtained by using crop straw On this basis, the preparation method comprises the following steps:

[0013] a. Proportion of raw materials according to the following mass proportions: 290-310 parts of crop straw, 9-18 parts of catalyst;

[0014] b. Put the raw materials prepared in step a into the reaction kettle, then add steam, distill and cool at 160-175°C for 185-260 minutes, then add 0.2-0.4 parts of hydrogen with a purity of 99%, and the hydrogenation reaction takes 35 After ~45 minutes, cool to 29~31°C to obtain 2-furanmethanol;

[0015] c. Add 65-75 parts of 2-furan methanol, 15-25 parts of ethanol with an alcohol content of 98%, and 4-6 parts of vegetable oil into the reaction kettle and mix evenly, heat up to 30-40°C, and carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com