Melt-spinning yarn breaking prompt system

A technology of broken yarn and melt spinning, which is applied in the field of prompting system for broken yarn of melt spinning, which can solve problems such as fiber winding and device jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

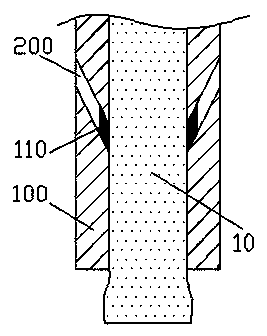

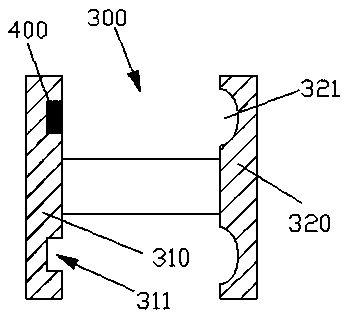

[0015] refer to figure 1 and figure 2 , in this embodiment, the melt-spinning broken filament warning system includes a nozzle 100 filled with melt 10, an infrared light source 200 is arranged in the nozzle 100, a reflective coating is arranged on the inner wall of the nozzle 100, and the nozzle 100 After the sprayed melt 10 is condensed, it is rewound by a rewinding bobbin 300, and the two ends of the rewinding bobbin 300 are respectively provided with a circular first baffle 310 and a second baffle 320. An infrared sensing probe 400 for detecting infrared rays is arranged on the first blocking piece 310, and the infrared sensing probe 400 is electrically connected with the monitoring circuit.

[0016] The monitoring circuit monitors the infrared signal sensed by the infrared sensing probe 400 at a fixed frequency, and when the infrared signal is interrupted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com