Folding clamp for suit pant belt

A stacking fixture and stacking technology, which is applied in the field of sewing machine accessories, can solve problems such as irregular stacking, different stacking effects, and failure to meet customer requirements, and achieve the effects of reasonable structure setting, neat stacking, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

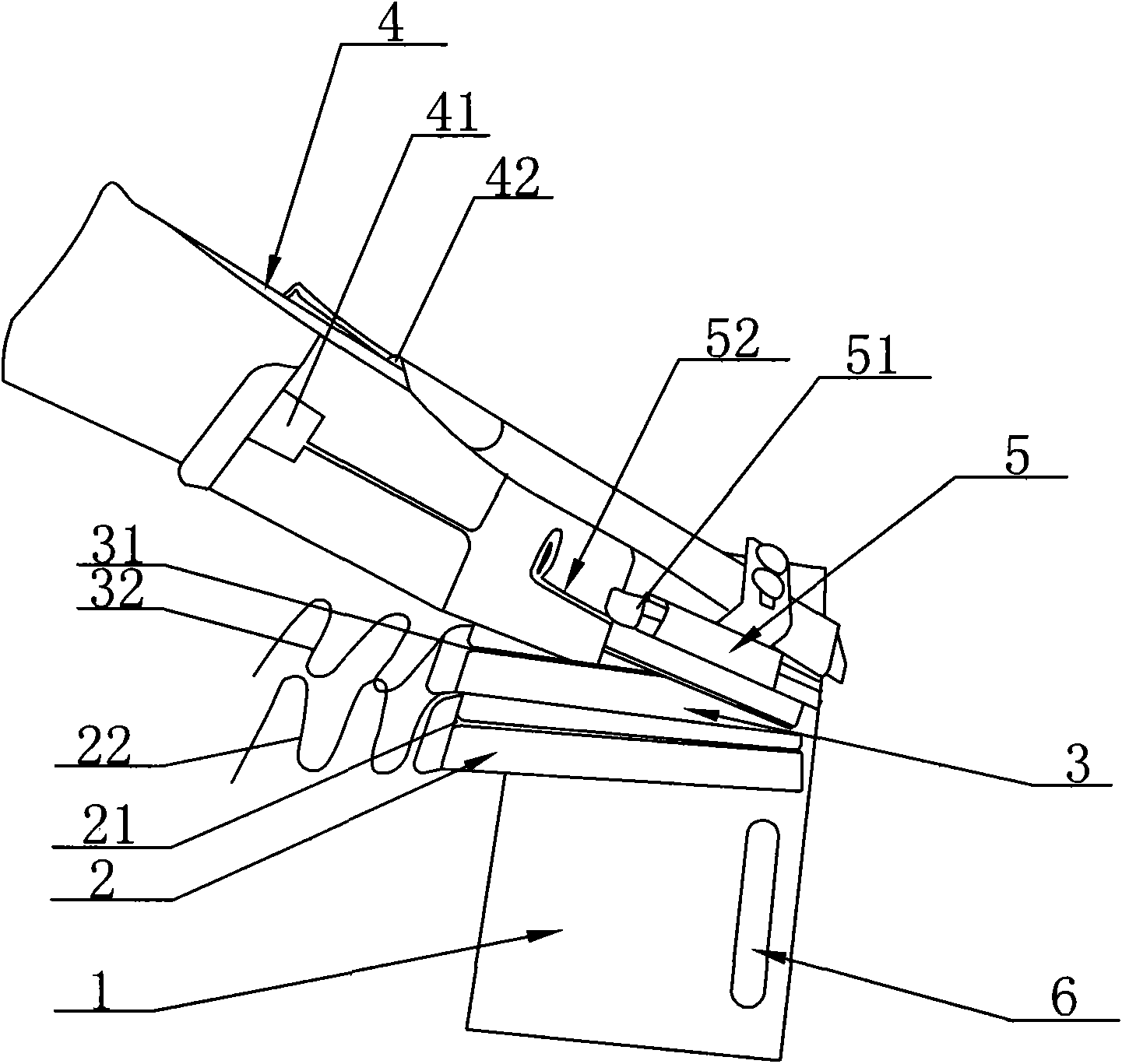

[0011] see figure 1 , A trousers waistband stacking fixture disclosed in the present invention includes a fixing plate 1, and a first stacking plate 2 and a second stacking plate 3 are fixed on the fixing plate 1. The first stacking plate 2 There is a first stacking channel 21 on it, and a second stacking channel 31 is provided on the second stacking plate 3 . The first stacking channel 21 and the second stacking channel 31 face the same direction, and the first stacking channel 31 The front end of the channel 21 is fixedly provided with a first limit rod 22, and the front end of the second stacking channel 31 is fixed with a second limit rod 32. The first limit rod 22 and the second limit rod 32 are both in the shape of a The "S"-shaped structure is arranged, one end of the fixing plate 1 is fixed forward and upward and is provided with a third stacking plate 4, and the left end of the third stacking plate 4 is provided with a third stacking channel 41. The right end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com