Tunnel water gushing treatment structure and construction method thereof

A construction method and technology for controlling structures, which are applied in the directions of drainage, earthwork drilling, safety devices, etc., can solve problems such as damage to side wall support, flood damage, hollowing out and collapse of surrounding rock structures, etc., achieving low cost, easy construction, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

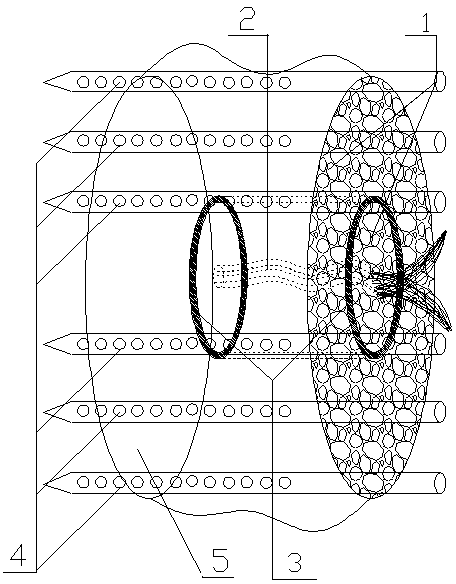

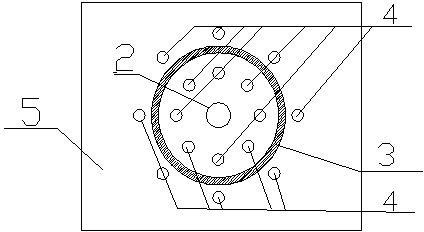

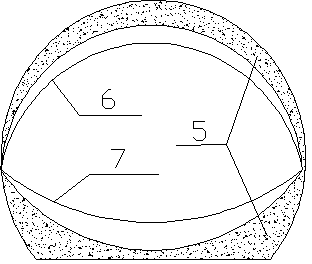

[0035] A tunnel water gushing treatment structure, such as figure 1 , figure 2 with image 3 As shown, the tunnel is a split tunnel structure, the right line of the tunnel is 1520 m long, the left line is 1511.7 m long, and the single-hole clearance is 10. 25 m x 5. 5 m. The gushing water column is jet-shaped, with a diameter of 40-50 mm, a length of 4 m, a height of 8 m, and a flow rate of 55 m3 / h. The surrounding rocks in the gushing face are dilotic quartz schist interbedded with biotite chlorite plagioclase , the rock mass is broken and fractures are developed, which belongs to the structure of fault compression zone. Therefore, the culvert pipe 3 is buried at the water head to control the water flow direction, the broken surrounding rock around the culvert pipe is replaced with gravel 2 to filter the sediment, and the soft foundation at the foot of the wall is replaced with poured concrete; Reinforce the lining to prevent invisible damage caused by water gushing; dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com