Composite damping shock absorber for textile machinery

A composite damping, textile machinery technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems that metal materials do not play a further role, the heat dissipation capacity is insufficient, and the structure of rubber shock absorbers is complex. Achieve the effect of reducing vibration, simple and compact structure, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

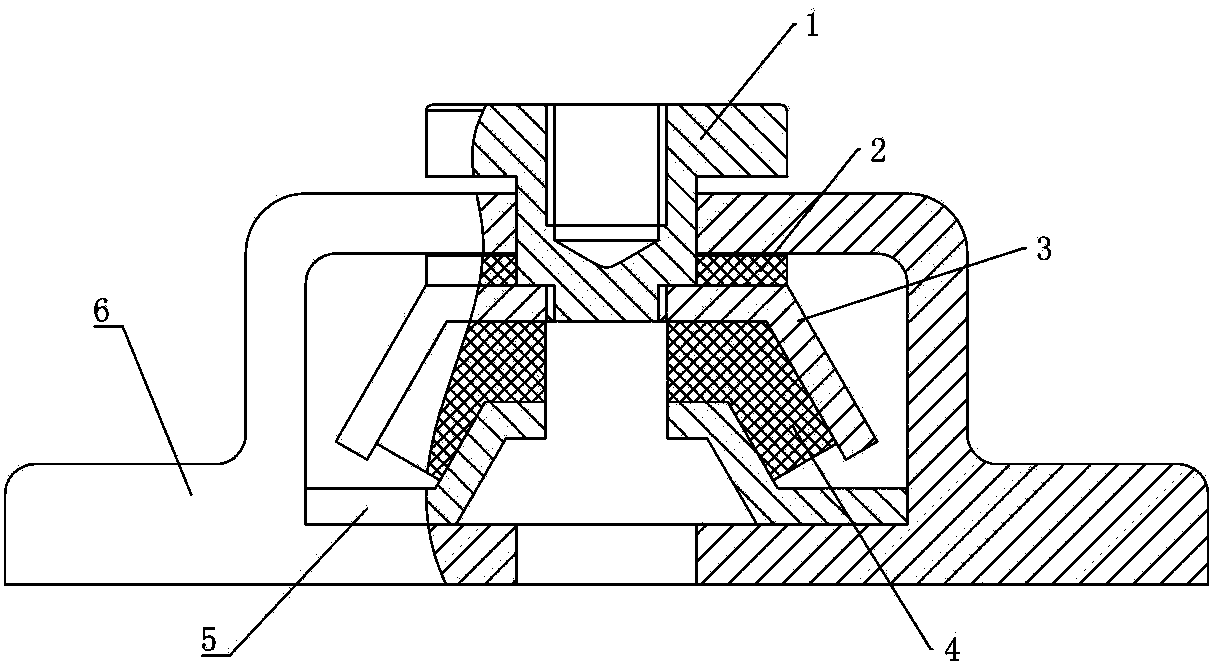

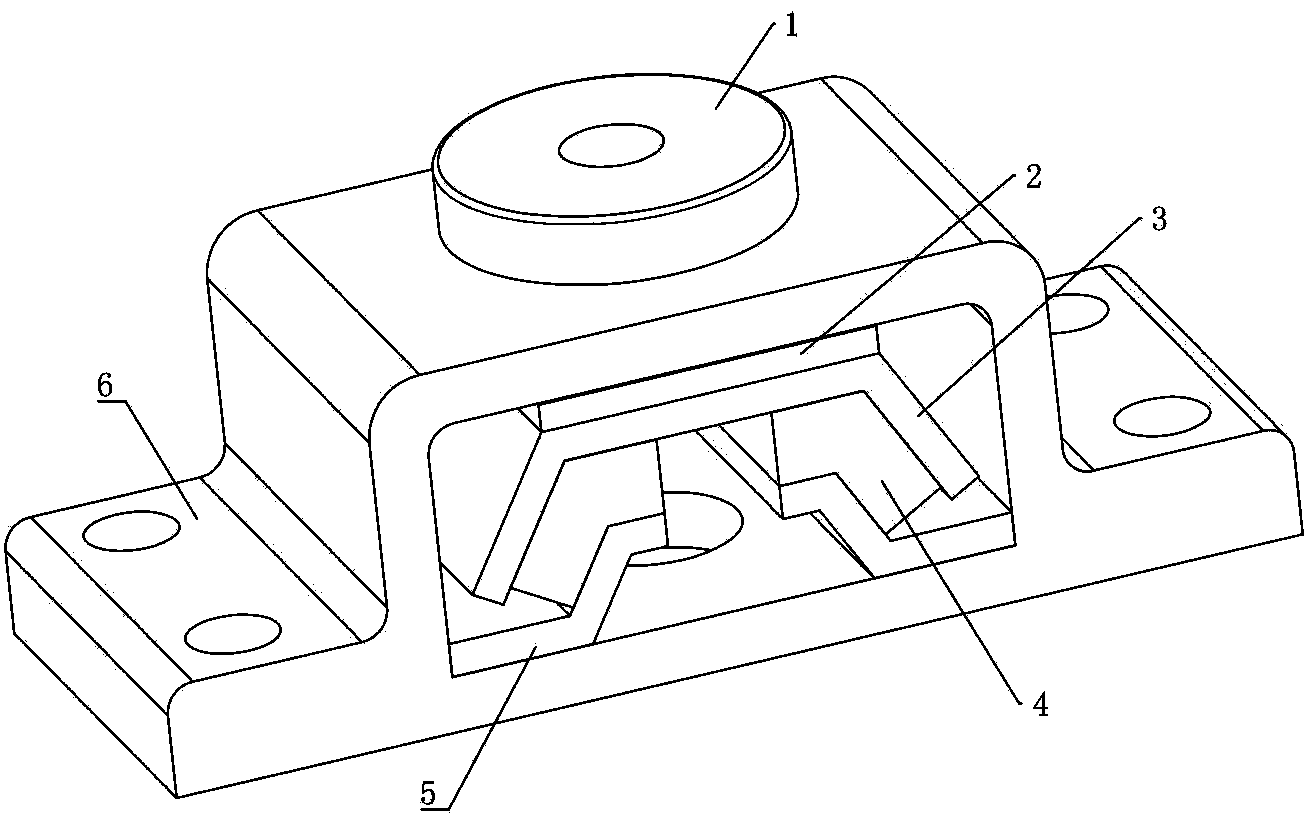

[0024] Such as figure 1 As shown, a composite damping shock absorber for textile machinery mainly includes a shock absorbing rod 1 for bearing supporting force, a shock absorbing assembly for absorbing shock, and a base 6 .

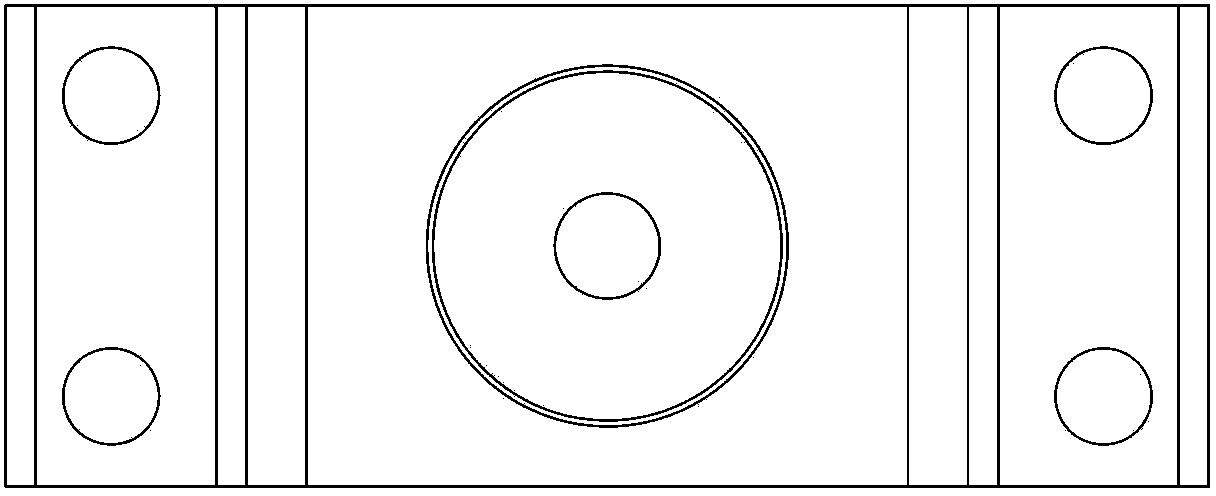

[0025] Such as Figure 9 As shown, the base is a cylinder with a cross-section in the shape of a mouth; the mouth-shaped structure forms a fixed cavity 6-3 that runs through both sides of the base in the horizontal direction (helping to dissipate heat); the upper side of the fixed cavity is the upper top plate of the base 6-1, the lower side of the fixed cavity is the lower top plate 6-2 of the base, and the upper top plate is also shaped on the upper top plate through hole 6-4.

[0026] Such as image 3 As shown, the shock absorbing assembly is positioned in the fixed cavity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com