Device and method for measuring wireless receiving and sending ultrasonic brine baume degree, evaporation capacity and liquid level

A liquid level measurement device, wireless transceiver technology, applied in the field of wireless transceiver ultrasonic brine Baume, liquid level measurement device, evaporation, can solve the problems affecting data accuracy, affecting measurement accuracy, time difference, etc., to achieve reliable testing Accurate, guaranteed precision, moderately weighted results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

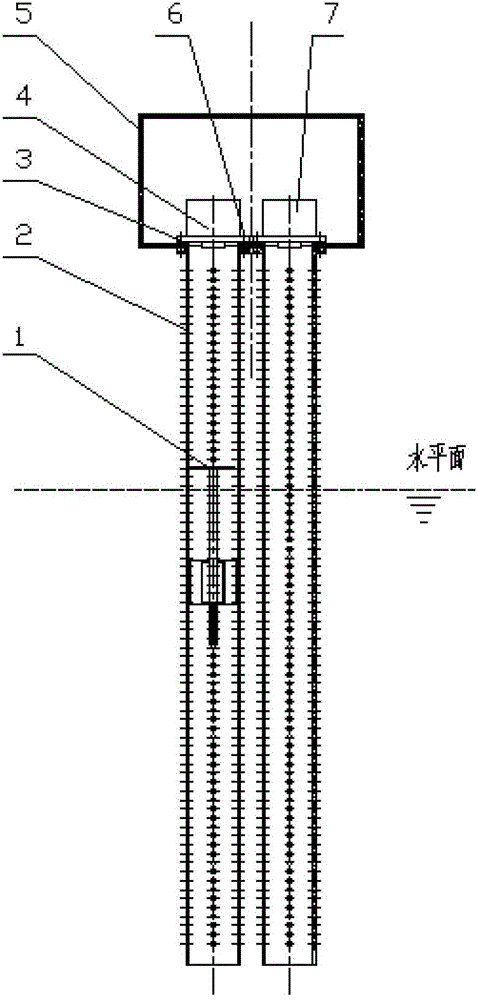

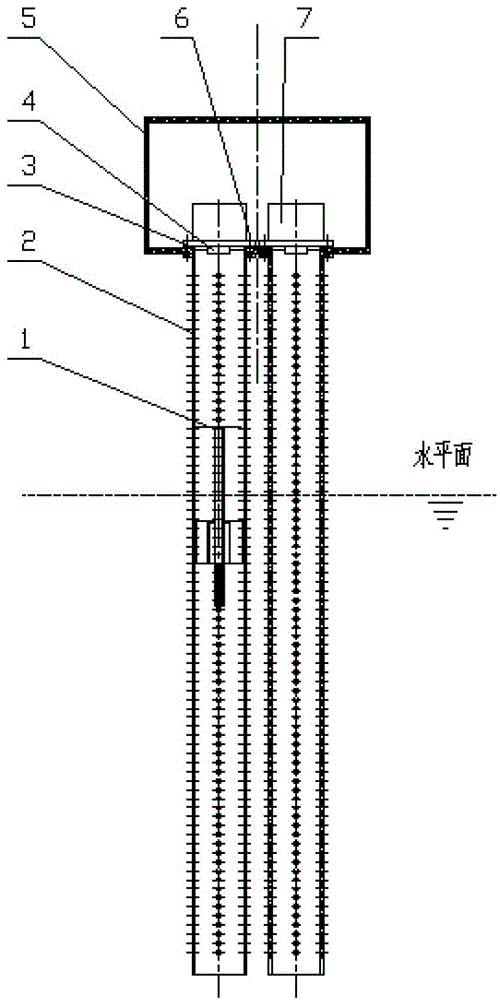

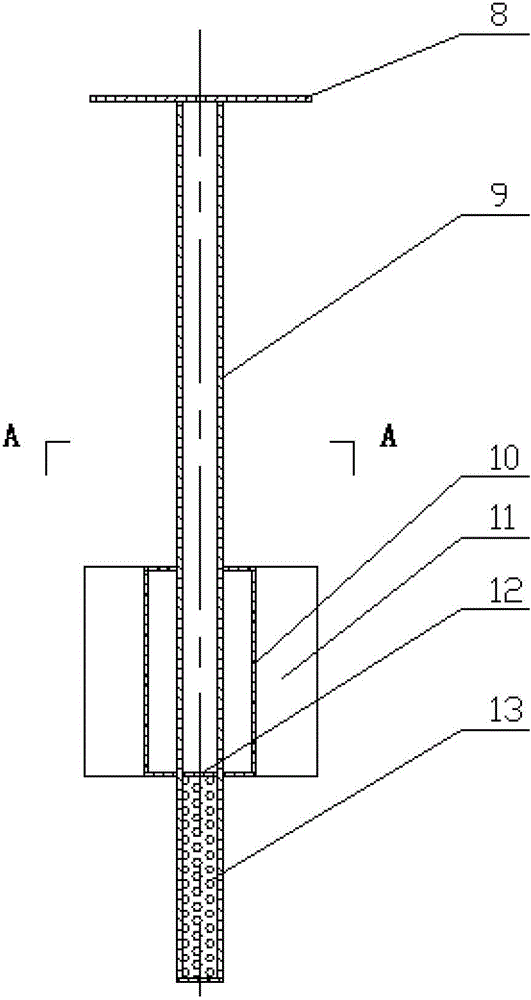

[0051] A wireless transmission and reception of ultrasonic brine baume, evaporation, and liquid level measuring device, which is composed of a measuring box 5, a measuring tube 2, a reflecting float 1, a wireless transmitting and receiving ultrasonic measurement control circuit, two fixed side by side in the lower part of the measuring box Measuring tube, the upper end of the measuring tube is fixedly mounted on the bottom surface of the measuring box by screws 6. The tube wall of the measuring tube is uniformly made with through holes, a reflecting float is placed in a gap in a measuring tube, and a wireless transceiving ultrasonic measurement control circuit is installed in the measurement box. The wireless transceiving ultrasonic measuremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com