Liquid crystal display (LCD) screen and display device

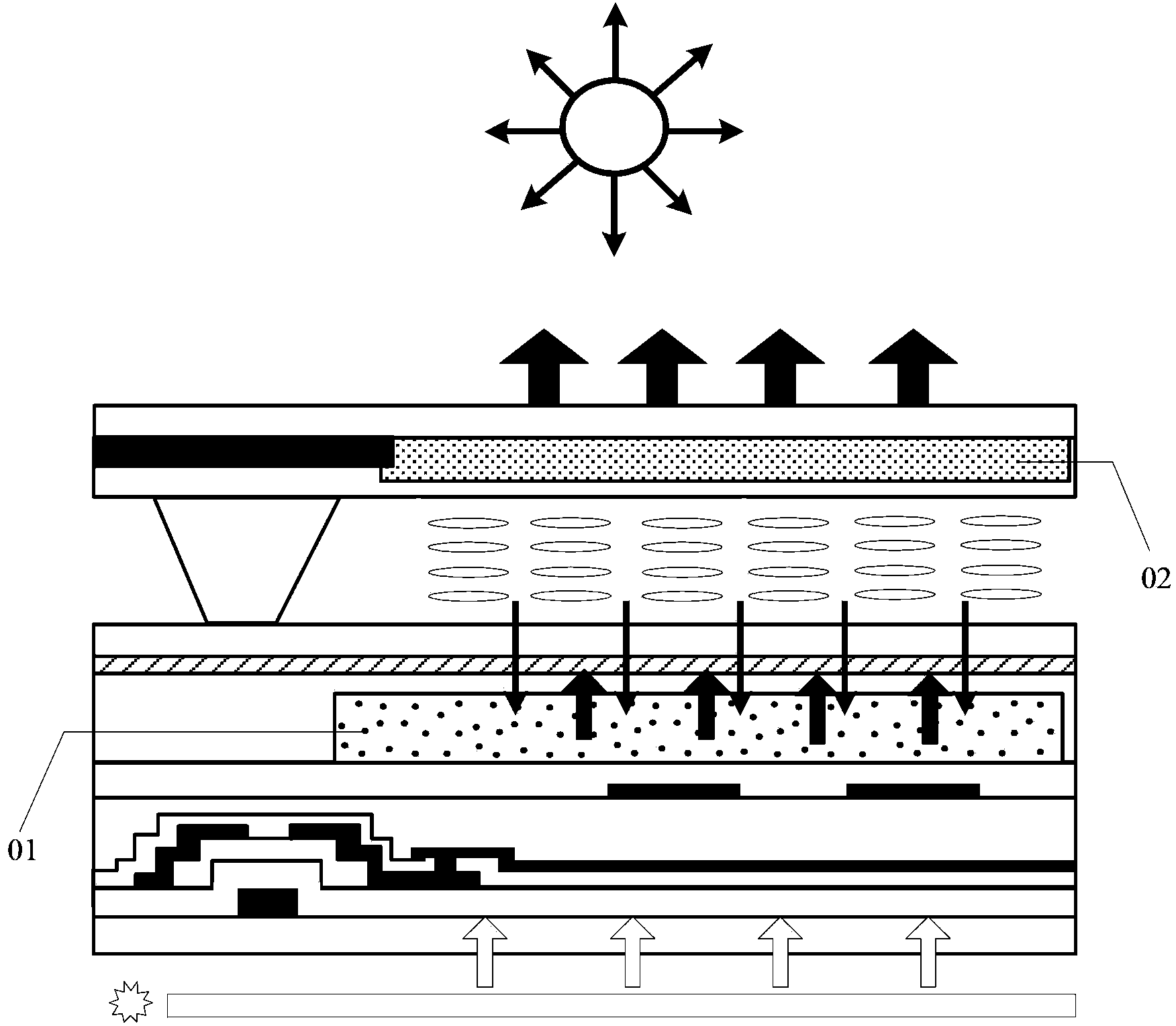

A liquid crystal display and liquid crystal layer technology, applied in optics, instruments, nonlinear optics, etc., can solve the problem of reducing the aperture ratio of the pixel unit of the liquid crystal display, and achieve the effect of improving viewability and enhancing display brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

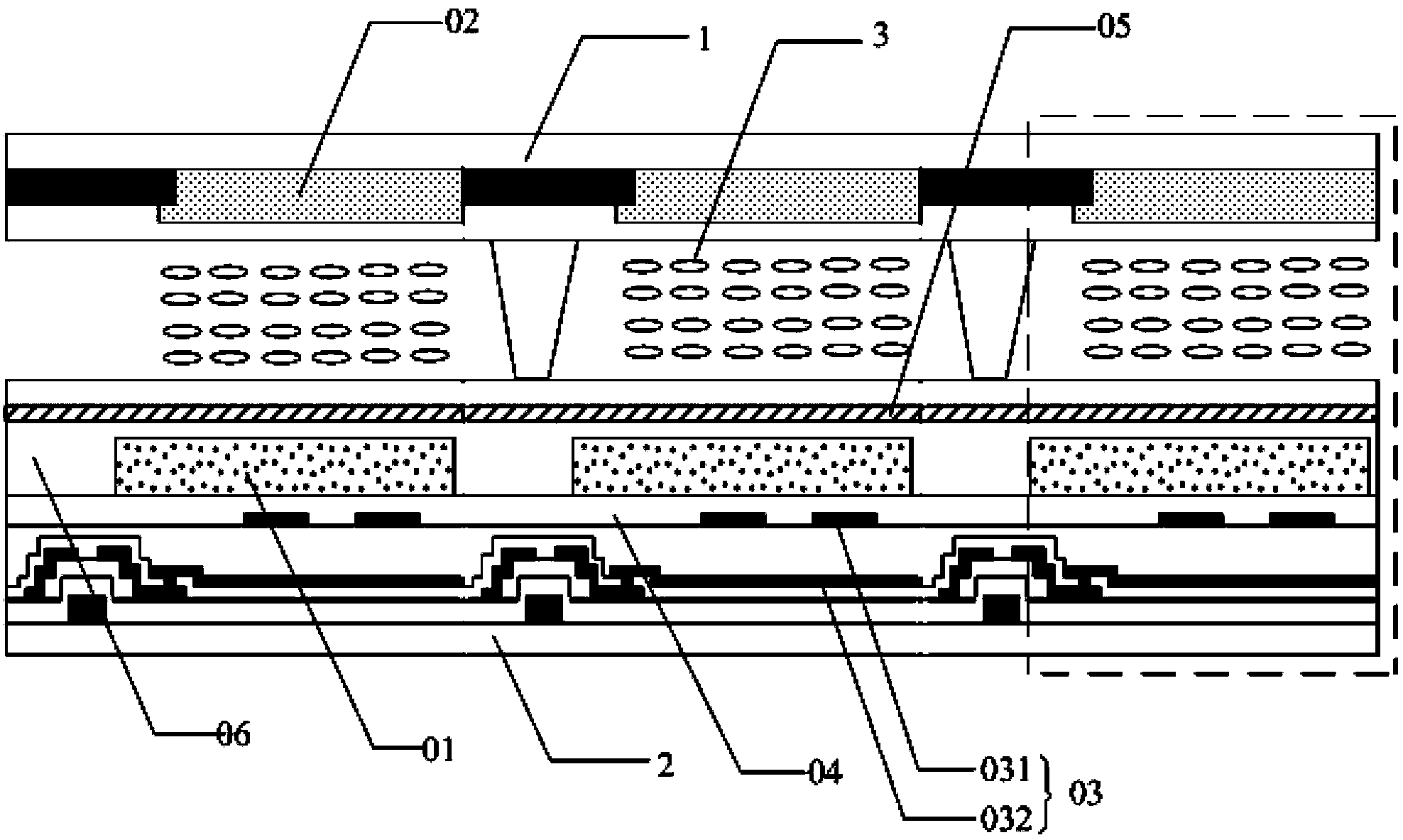

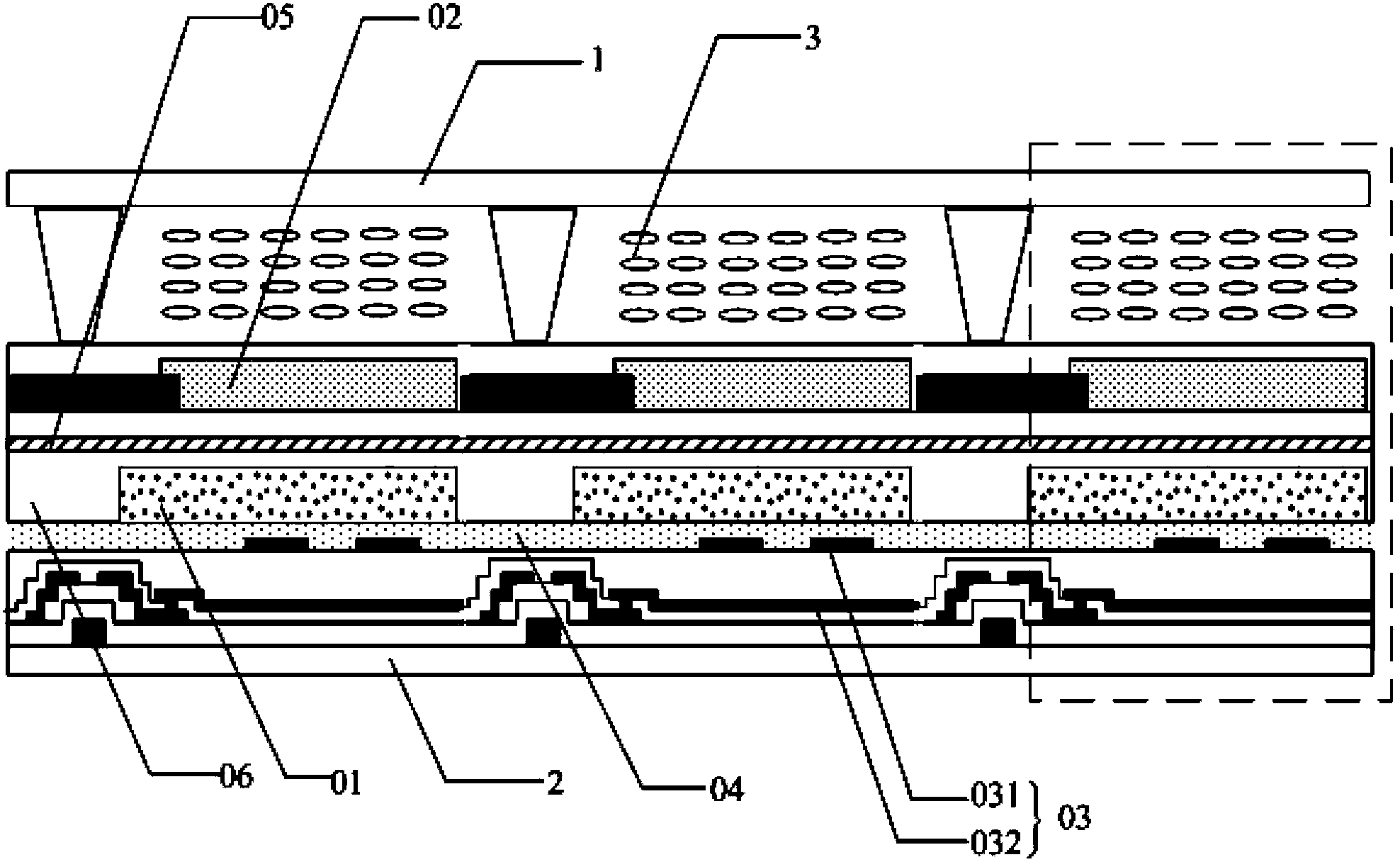

example 1

[0048] The color filter 02 in the liquid crystal display is arranged on the opposite substrate 1; the manufacturing process of the array substrate 2 includes the following steps:

[0049] (1) Forming a pattern including the gate 07 on the array substrate 2, such as Figure 3a shown;

[0050] (2) Form a gate insulating layer 08 on the pattern including the gate 07, such as Figure 3b shown;

[0051] (3) Forming a pattern including the active layer 09 on the gate insulating layer 08, such as Figure 3c shown;

[0052] (4) Forming a pattern including the source and drain electrodes 10 on the pattern including the active layer 09, such as Figure 3d shown;

[0053] (5) A first insulating (PVX) layer 11 is formed on the pattern including the source and drain electrodes 10 and the gate insulating layer 08, and via holes are formed on the first insulating layer 11, such as Figure 3e shown;

[0054] (6) Form a pixel electrode 032 on the first insulating (PVX) layer 11, and con...

example 2

[0063] The color filter 02 in the liquid crystal display is arranged on the array substrate 2, and the manufacturing process of the array substrate 2 includes the following steps in addition to steps (1) to (13) in Example 1:

[0064] (14) Forming a black matrix 14 on the resin layer 13, such as Figure 4a shown;

[0065] (15) Form the color filter 02 on the resin layer 13, such as Figure 4b shown;

[0066] (16) Form a protective layer 15 on the black matrix 14 and the color filter 02, such as Figure 4c shown.

[0067] Based on the same inventive concept, an embodiment of the present invention also provides a display device, including the above-mentioned liquid crystal display provided by the embodiment of the present invention. Since the problem-solving principle of the device is similar to that of the aforementioned liquid crystal display, the implementation of the device Reference can be made to its implementation, and repeated descriptions will not be repeated here. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com