A target film flattening device and method for nuclear physics in-beam experiment

A flattening device and a technology of nuclear physics, applied in the field of atomic nuclei, can solve problems such as inability to meet use requirements, and achieve the effects of simple structure, flexible use, and guaranteed flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

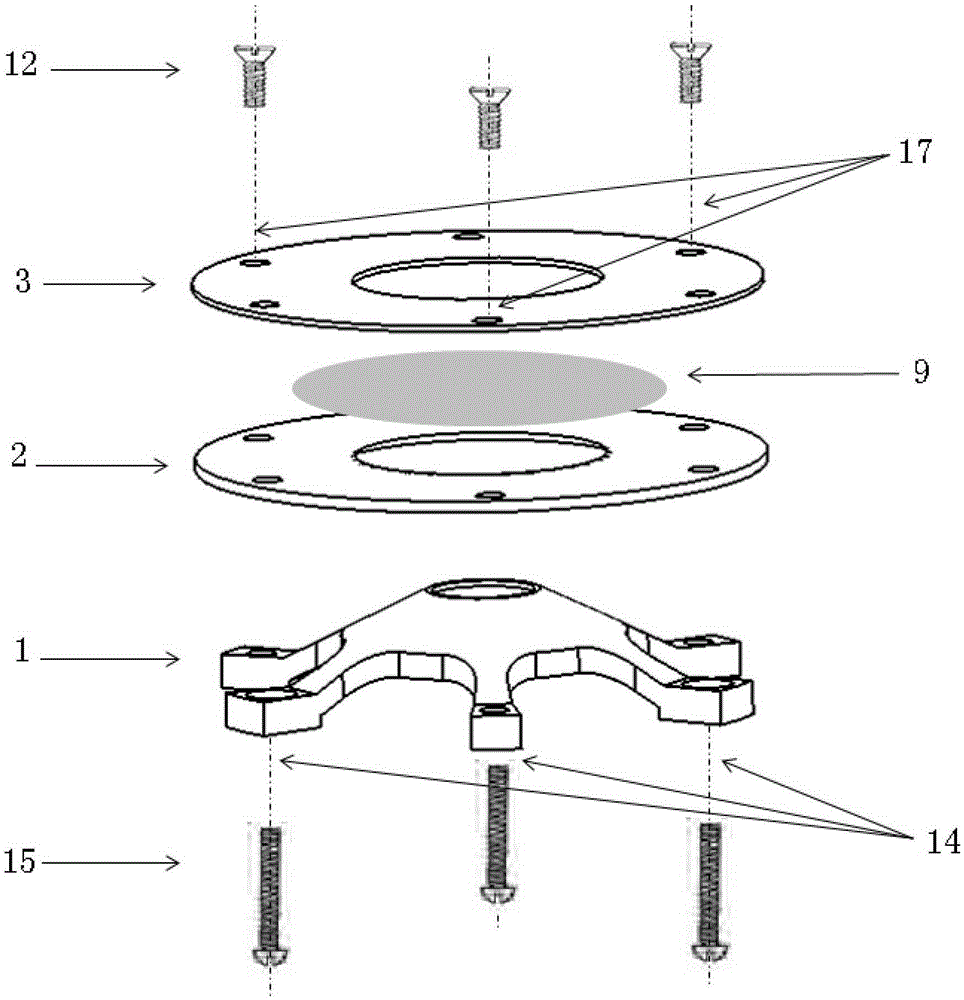

[0036] like figure 1 As shown, it is a nuclear physics in-beam experiment target membrane flattening device, which includes a support frame 1 and two ring pieces 2, 3. Wherein, the center of the support frame has a 126.9-degree conical frustum, and several legs are evenly distributed around it, and each leg is provided with a threaded hole 14 .

[0037] Wherein, the thickness of a ring piece 3 is 1mm, and several threaded holes 17 are evenly distributed on the outer circumference of this ring piece, and these several threaded holes are matched with the threaded holes on the supporting frame legs; another ring piece 2 The thickness of the ring is 1mm, the outer circumference of the ring is provided with several 2.5mm through holes, the inner ring of the ring is provided with chamfers, the target film is placed on the chamfers, and the ring with chamfers The target membrane 9 is sandwiched between one piece and another ring piece. The specific dimensions above can be adjusted ...

Embodiment 2

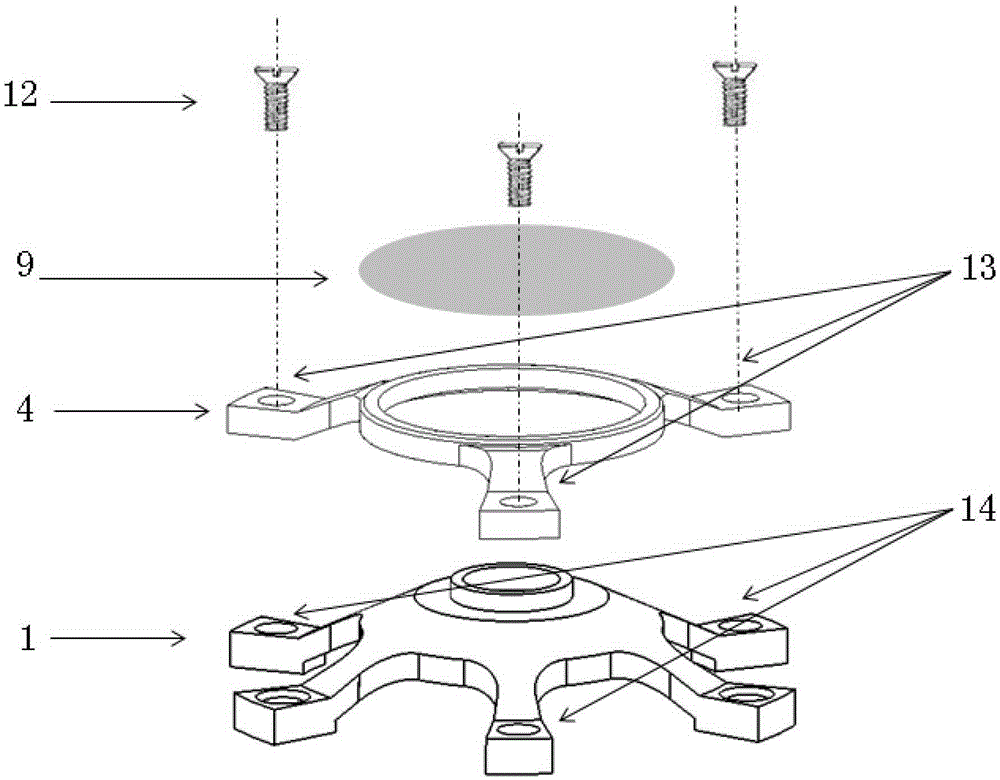

[0043] like figure 2 As shown, it includes a support frame 1 and a film frame 4 arranged on the top of the support frame. There is a truncated cone in the middle of the support frame, and several legs are evenly distributed around the truncated cone. Each leg is provided with a through hole 14. A central through hole is provided, and a circular boss is arranged on the central through hole; the film sticking frame includes a ring, and several legs are evenly distributed around the ring, and each leg is provided with a through hole 13, and the target film 9 is pasted on the On the ring of the film stand, the legs on the ring are matched with the legs on the support frame, and the through holes 13 of the legs on the ring are connected with the threaded holes 14 on the legs of the support frame by round head screws 12, Tighten the round head screw, and the round boss can move upwards, thereby pushing out the target membrane and flattening the target membrane.

[0044] Among them...

Embodiment 3

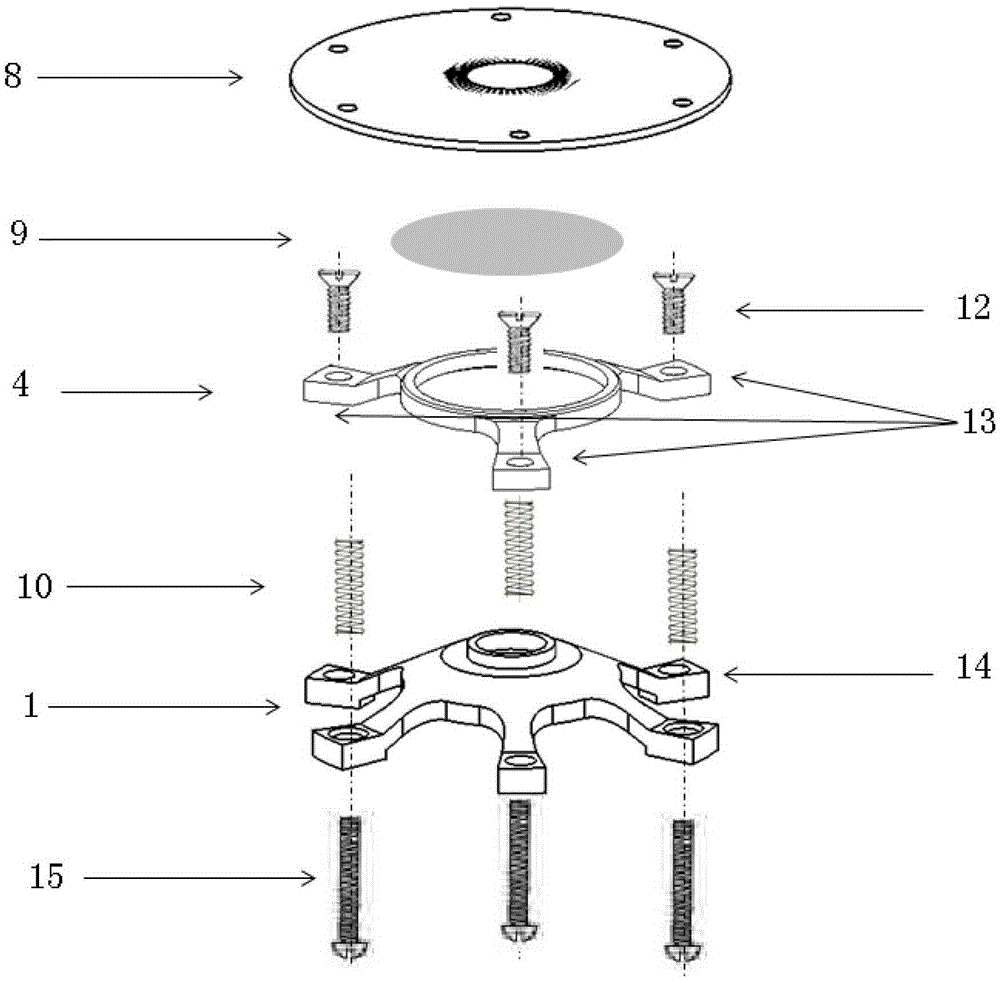

[0051] like image 3 As shown, the nuclear physics experiment target film flattening device provided by the present invention differs from Embodiment 2 in that it also includes a target lining and a blocking piece 8, and the target lining is pasted on the film frame 4, and the blocking piece It has a center hole, the center hole of the blocking piece is aligned with the center of the target lining, the target film 9 is sprayed on the target lining, the round head screw 15 connects the support frame 1 and the film sticking frame 4, and a spring 10 is also sleeved on the connecting piece , to adjust the height.

[0052] The method of the present invention is a sputtering method. Some targets cannot be self-supporting, and need to be sputtered on the target lining, and can be adjusted, and the target can be made separately. Adjust the screw, the block has a larger vertebral angle, and the six holes are all M2.5 threaded holes.

[0053] The method for flattening the target film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com