Permanent magnet motor magnetic steel installation and fixation retainer and permanent magnet motor magnetic cylinder comprising the same

A permanent magnet motor, fixed and maintained technology, applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problem of increasing the use of magnetic steel materials, being easily affected by high temperature or oil pollution, and long process time, etc. problems, to achieve the effect of improving production efficiency, simple and reasonable structure, and concise overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

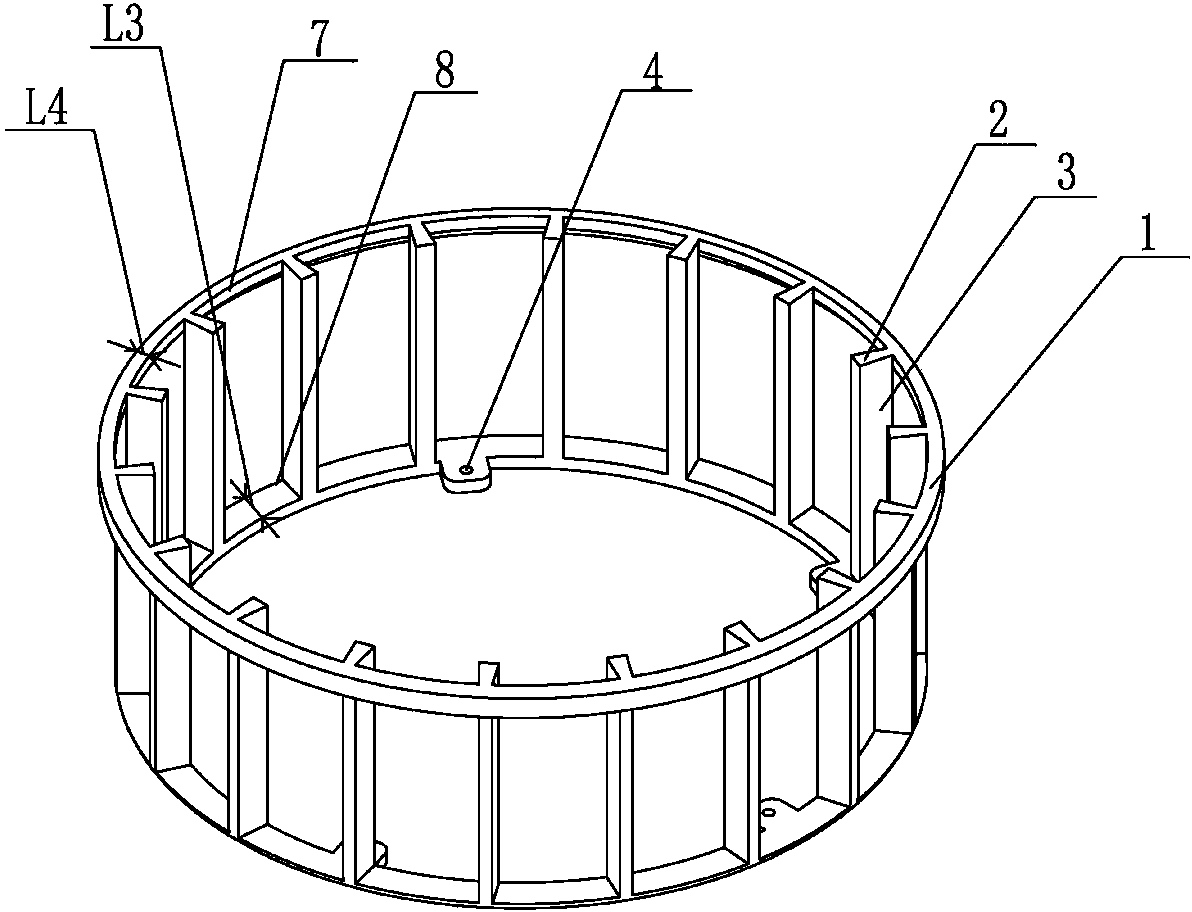

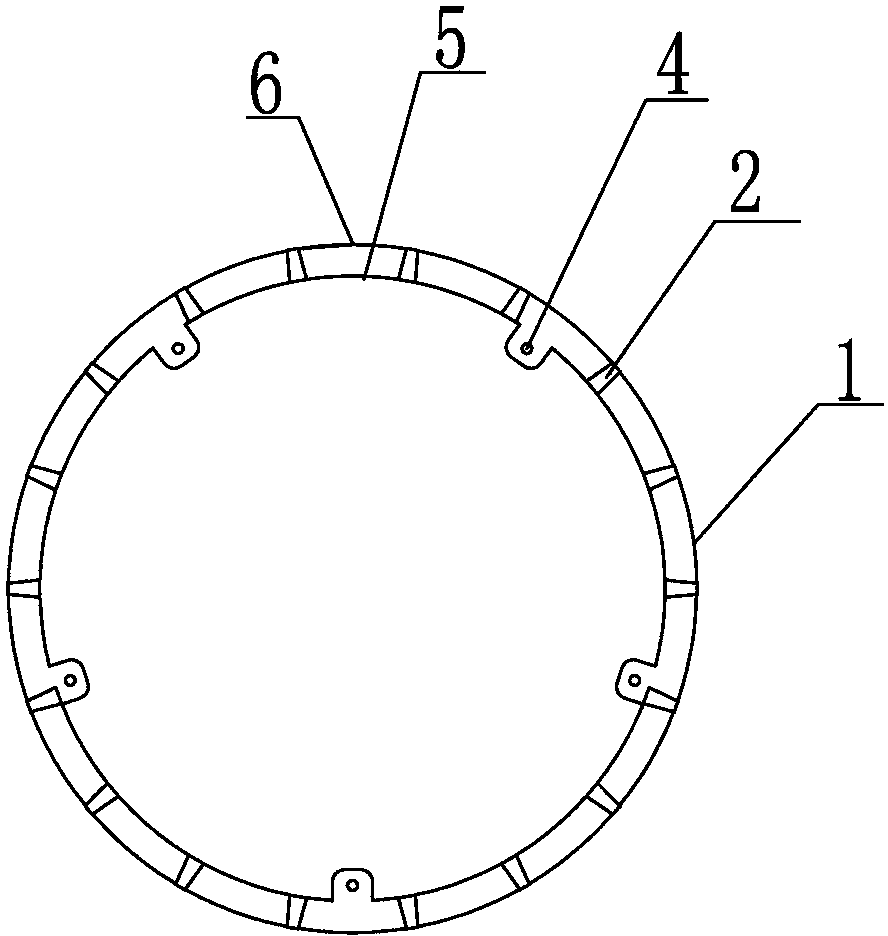

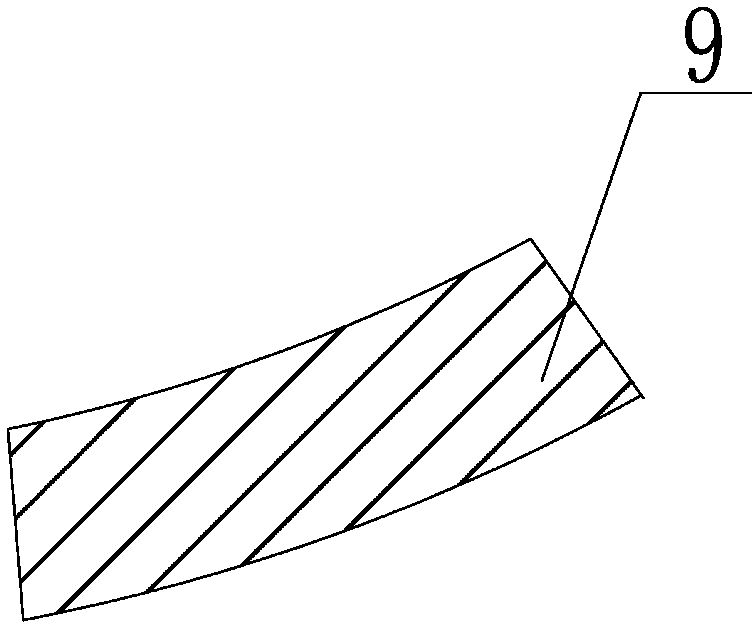

[0023] Such as Figure 1 to Figure 4 As shown, a permanent magnet motor magnetic steel installation and fixed cage, which includes a cylindrical cage-shaped cage body 1, the cage body 1 is provided with magnetic isolation strips 2 according to circular arcs, adjacent magnetic isolation strips 2 and the cage The space enclosed between the main body 1 is the magnetic isolation strip groove 3, and the opening of the magnetic isolation strip groove 3 is set such that the diameter L1 of the inner opening 5 is small, and the diameter L2 of the outer opening 6 is large.

[0024] Since the opening of the magnetic isolation strip slot 3 is set to have a small diameter L1 on the inner side and a large diameter L2 on the outer side, when the magnetic steel rotates, the magnetic isolation strips on both sides of the inner opening can produce a reaction force on the magnetic steel strip, which can effectively prevent the magnetic steel The strip is loose. The magnetic steel strip can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com