Integrated controller module in motor of electric vehicle

A controller module, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of phase current copper connectors easy to heat and oxidize, copper connectors to increase contact resistance, increase heat generation, etc. The effect of long life, reduced assembly wiring harness, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

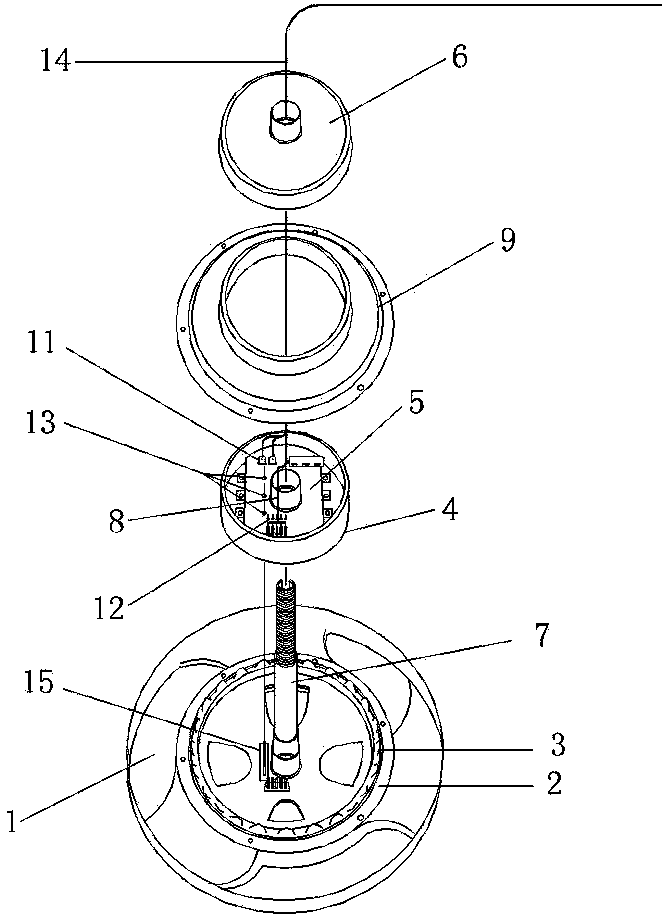

[0015] figure 1 It shows an embodiment of an integrated controller module in an electric vehicle motor of the present invention, which includes a motor housing 1 installed in the electric vehicle, and a rotor 2 and a stator 3 are installed in the motor housing 1. The top of the motor housing 1 is provided with a motor cover 9 that rotates with the rotor 3, and a controller module 4 is also arranged in the motor 1, and a control main board 5 is installed in the controller module 4, and the controller module 4 is fixed on the On the stator 3, and the surface of the controller module 4 is also provided with a controller cover 6, the controller cover 6 and the motor cover 9 are fixed and rotate synchronously, the center of the stator 3 is provided with a shaft 7, and the controller module The center of 4 is provided with a positioning hole 8, and the controller module 4 is fixed on the stator 3 by setting the positioning hole 8 on the shaft 7, and the main power input terminal 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com