Full-drive leveler

A leveler and full-drive technology, applied in the field of full-drive levelling (leveling) machines, can solve problems such as excessive load on the transmission shaft and twisted and twisted work rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

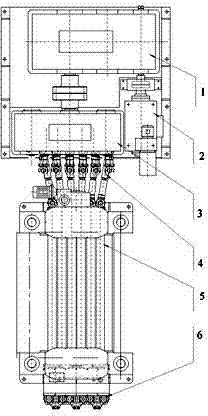

[0006] Refer to attached figure 1 , The full-drive leveler according to the present invention includes a main motor 2, a reducer 1, a distribution box 3, a transmission shaft 4, a work roll 5 (the above may be referred to as the main power system) and an auxiliary power system 6. The transmission shaft 4 can be, for example, a universal joint or a universal joint. The auxiliary power system 6 may include a hydraulic motor or a special motor, and its transmission system may also be similar to the main power system, including a reducer, a distribution box and a transmission shaft. Preferably, the full-drive leveler according to the present invention also includes an automatic control system, a torque monitoring sensor is set on the work roll, and a load monitoring sensor is set on the transmission shaft, and both sensors will send the monitored data signals to the automatic control system system; in the normal and normal working state of the leveler (that is, the flatness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com