Unmanned electric forward-movement-type clamping vehicle

An unmanned and electric technology, applied in the direction of hoisting device, can solve the problems such as the inability to use unmanned automatic driving mode, which is not conducive to improving the efficiency of warehouse storage capacity, and the large size of the working channel space, so as to reduce vehicle running channels and reduce manpower. The effect of resource occupancy and reduction of total length and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

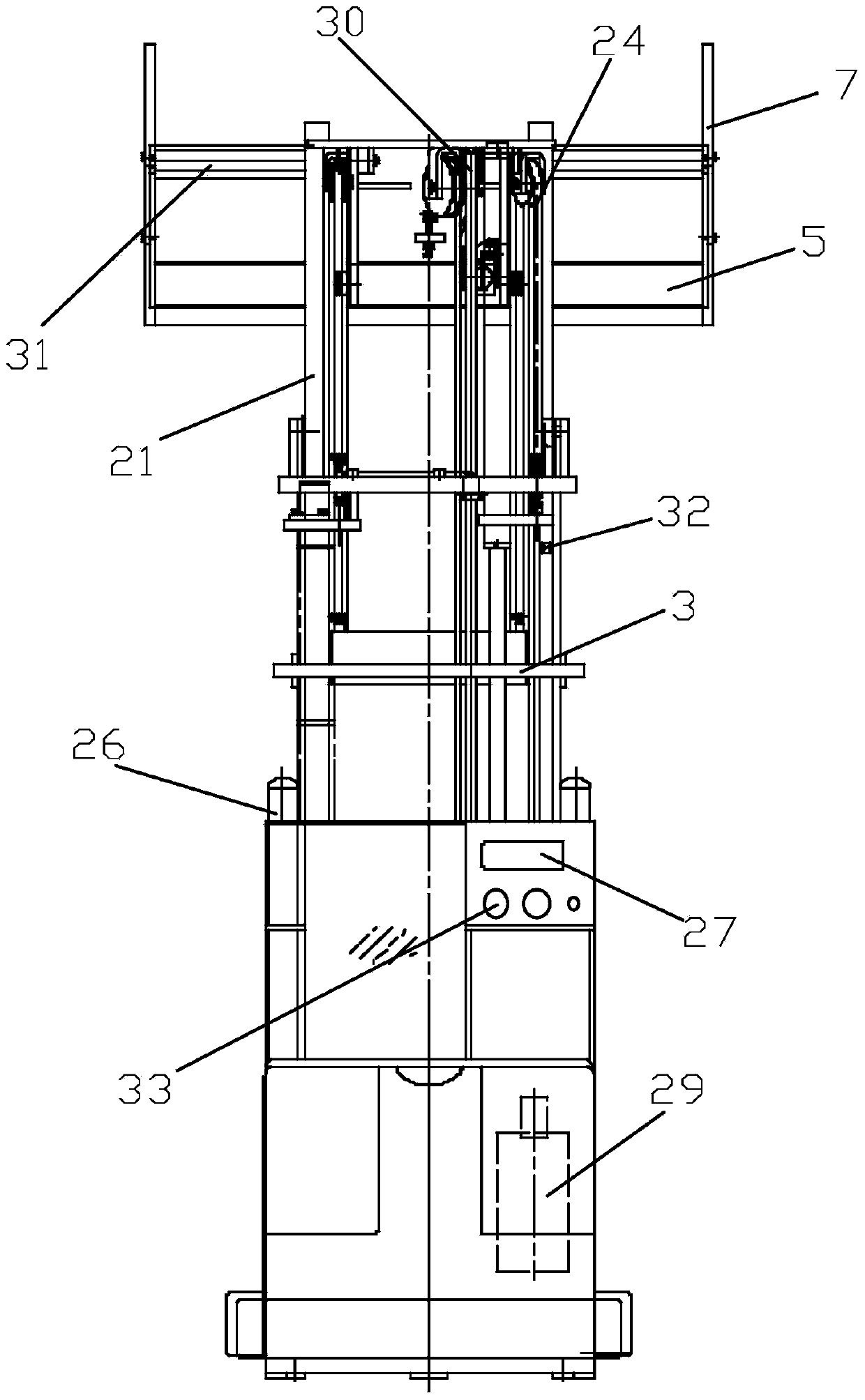

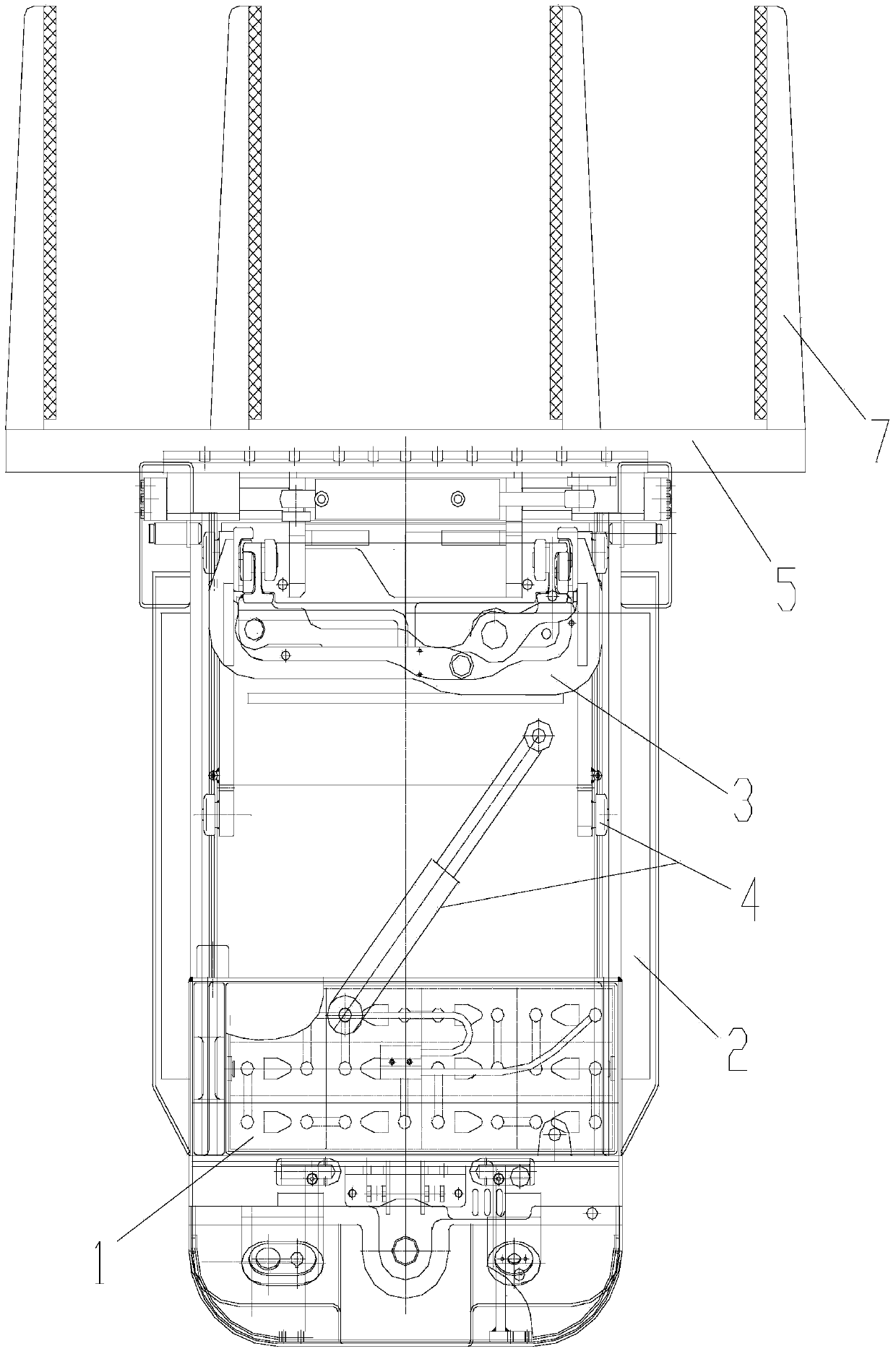

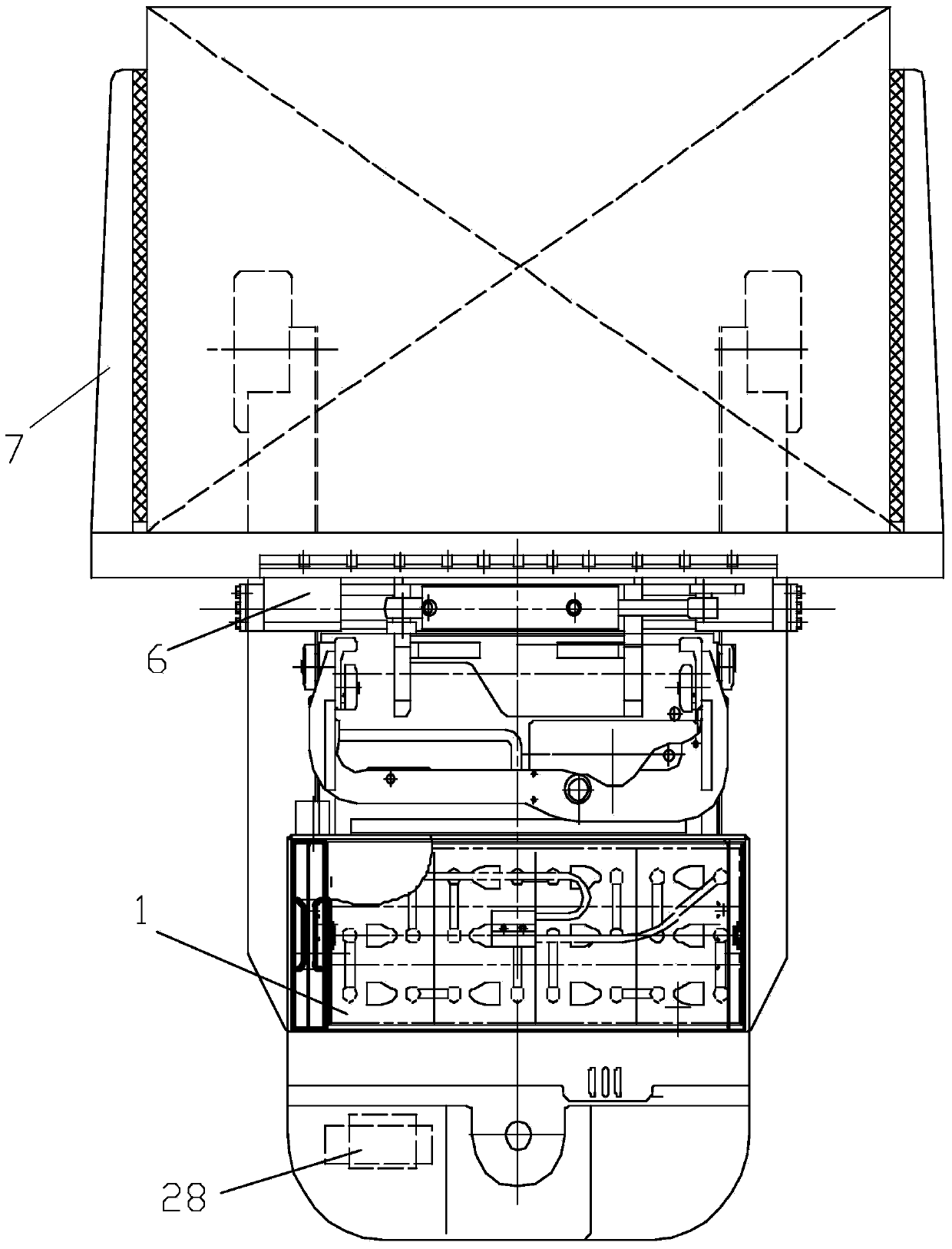

[0020] Attached below Figure 1-6 An embodiment of the present invention is described.

[0021] An unmanned electric forward-moving holding car has a car body 2 and a battery 1 mounted on it. The car body 2 is provided with an alarm 26 and a display 27 for displaying fault information. When the vehicle is in an abnormal state, it will automatically Generate a vehicle maintenance order, issue an alarm through the siren 26, display the fault information through the display 27, and automatically drive to the maintenance station designated by the vehicle; Alarm 26 sends an alarm, and travels to the vehicle charging station to carry out electric quantity replenishment before the automatic protection of the vehicle cuts off the power supply. The car body 2 adopts a three-wheel support type, a four-wheel support type or a five-wheel support type. The car body 2 is provided with a working device 3 that can be retracted up and down. Specifically, the working device 3 is a secondary o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com