Material pushing device of stainless steel solid melting furnace

A pusher, stainless steel technology, applied in furnaces, furnace components, furnace types, etc., can solve the problems of high labor intensity and high frequency of bundling, and achieve the effects of convenient operation, improved work efficiency, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

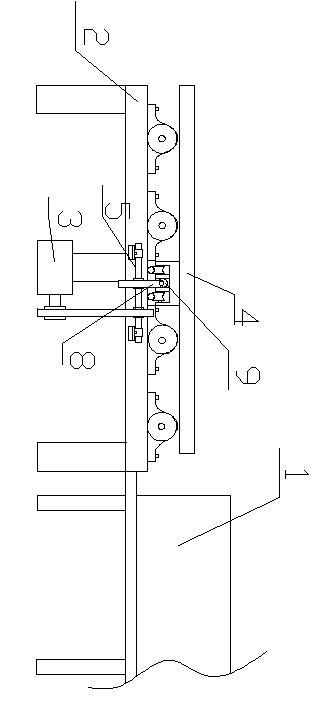

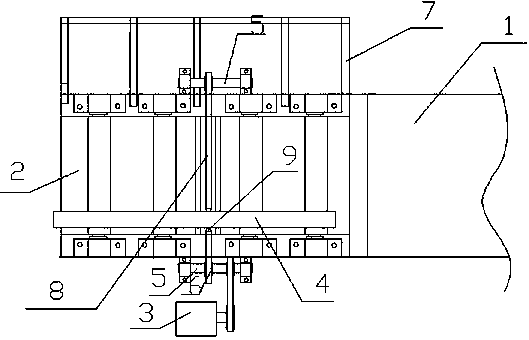

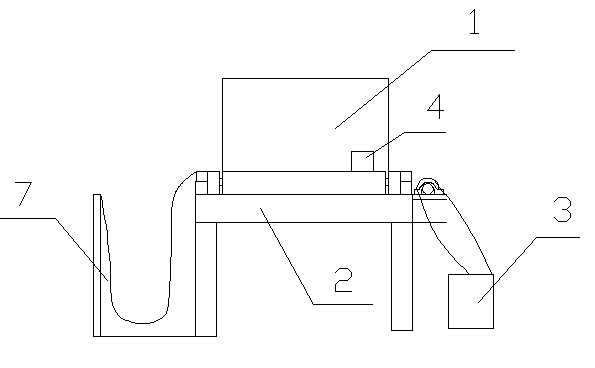

[0015] Such as figure 1 , 2 Shown in , 3: a kind of pushing device of stainless steel solid melting furnace of the present embodiment, comprises solid melting furnace 1 and the discharge conveyer frame 2 that is positioned at one end of the outlet of described solid melt furnace 1, and described discharge conveyer frame 2 is fixedly arranged There is a pushing device.

[0016] The pushing device includes a motor 3, a push rod 4, a gear 6, a chain 8, a cover rod 9, and a collecting frame 7; track wheels and a cover rod 9 are installed at the bottom of the push rod 4, and the cover rod 9 is located at two between the track wheels; the track wheels are respectively slid and fixed on the two parallel tracks set on the discharge conveyor frame 2, and the two ends of the tracks are respectively provided with bearings with seat belts to rotate and fix on the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com