Base-free heat dissipater

A radiator without a base technology, which is applied in the field of structure improvement design of a baseless radiator, which can solve the problems of reducing the number of heat pipes that can be accommodated, inconvenient assembly, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

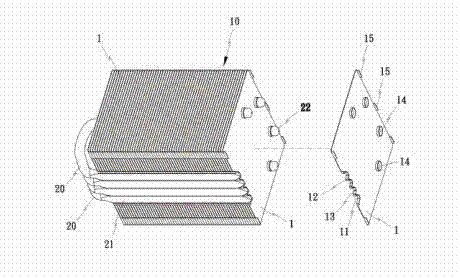

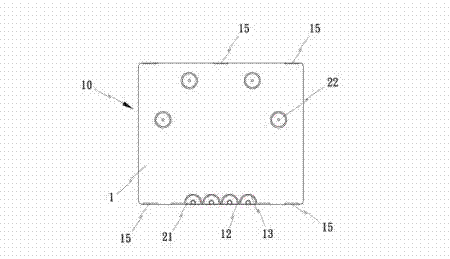

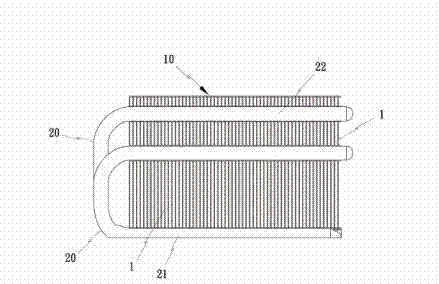

[0046] like Figure 1 to Figure 3 As shown, it is the first embodiment of the "baseless radiator" of the present invention used in the combined form of a horizontal radiator, which includes more than one heat sink module 10 and more than two plural heat pipes 20; wherein:

[0047] The heat sink module 10 is composed of a plurality of heat sinks 1 arranged in adjacent stacks, such as Figure 4 As shown, each cooling fin 1 is provided with a plurality of tightly fitting grooves 11 at the bottom, and there is a support rib 12 smaller than the groove depth between adjacent tight fitting grooves 11 (such as Figure 5 The height difference a) shown, and more than one limit rib 13 can be provided on the inner surface of the tight fitting groove 11 (such as Figure 4 );

[0048] The plurality of heat pipes 20 all have a heat-absorbing end 21 and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com