Method for evaluating ground coefficient K30 values of high-speed railway bed coarse particle soil padding

A high-speed railway and coarse-grained soil technology, which is applied in the field of foundation soil survey, infrastructure engineering, construction, etc., can solve problems such as the failure to complete the project, the increase of manpower and material resources, and the delay of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

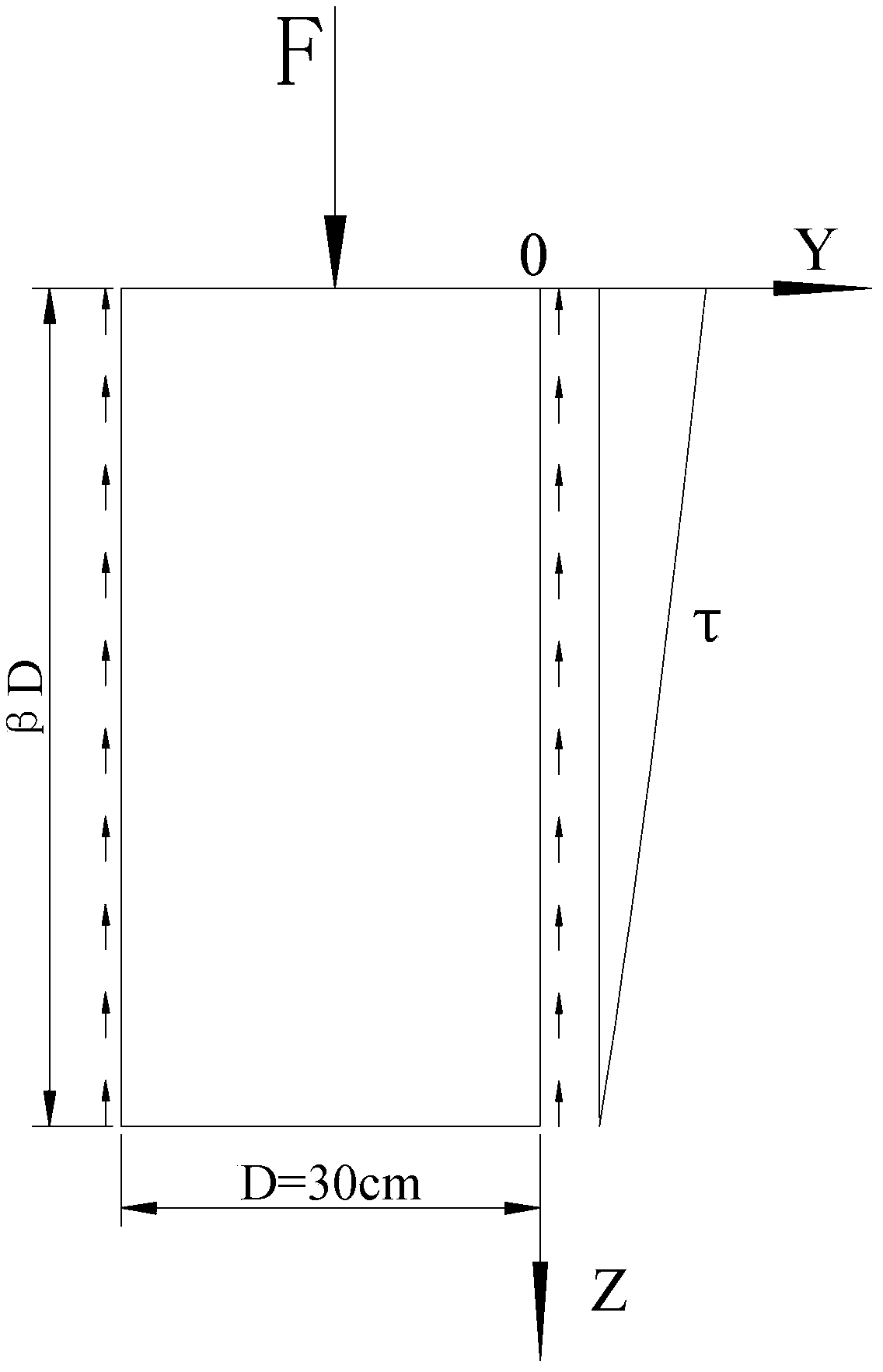

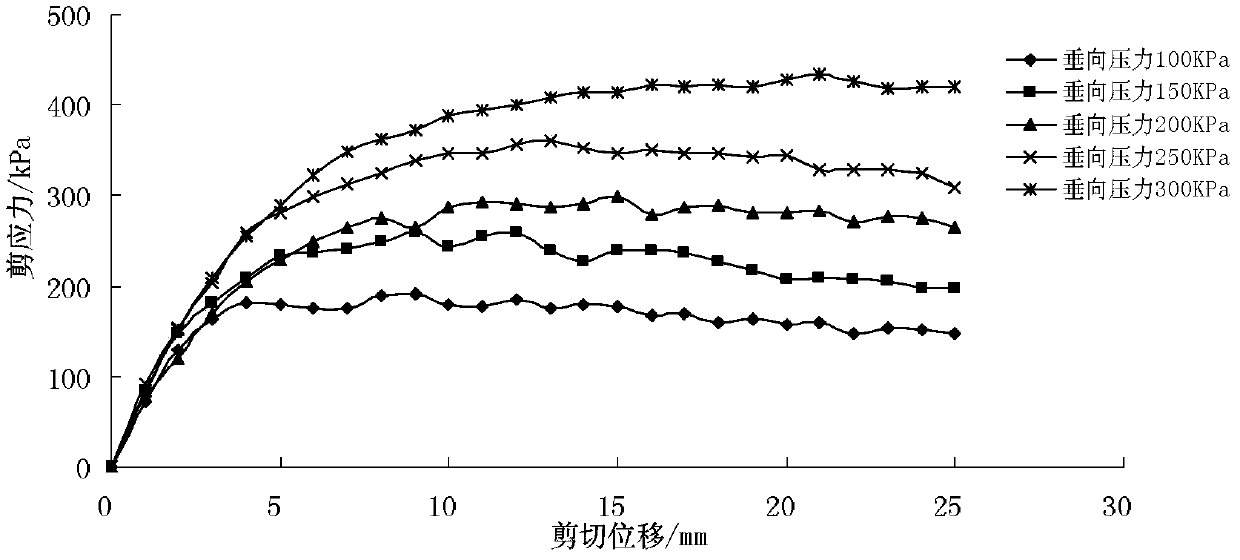

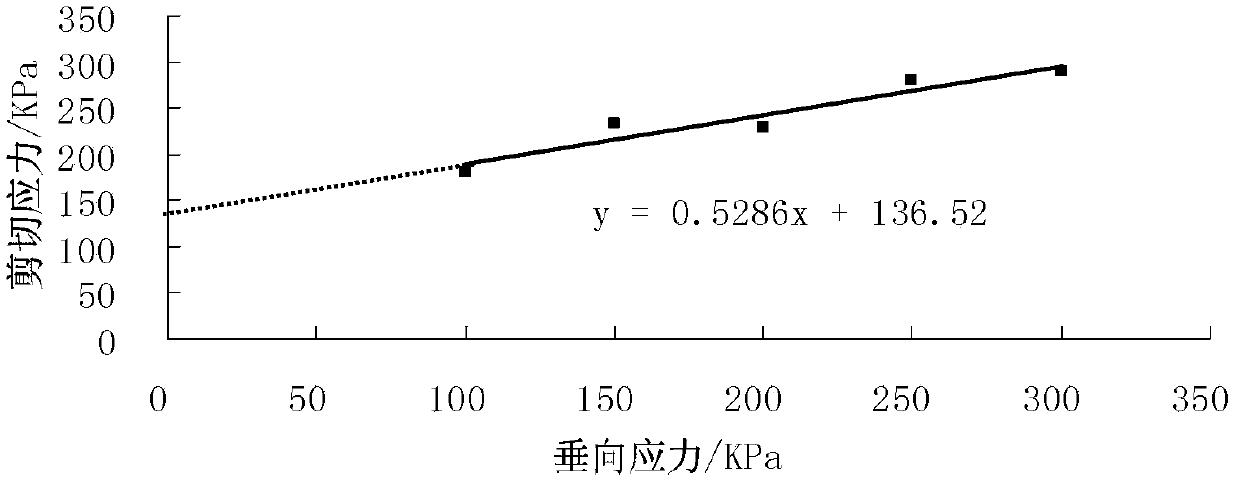

[0051] A specific embodiment of the present invention is that the subgrade coefficient K of a high-speed railway embankment coarse-grained soil filler 30 Estimation method, its steps are as follows:

[0052] A. Determination of the maximum dry density of the filler sample

[0053] The maximum dry density ρ of the filler sample measured from the maximum dry density test of coarse-grained soil dmax ;

[0054] B. Determination of the maximum bite force of the filler sample under the control value K of the compaction coefficient

[0055] B1, prepare the shear test sample: according to the maximum dry density ρ of the filler sample obtained in step A dmax , the control value K of the filling compaction coefficient of the subgrade structure layer of the high-speed railway to be filled (the control value K of the filling compaction coefficient can be found in the "High-speed Railway Design Code" (Trial) TB10621-2009), and the dryness of the shear test sample is calculated Density...

Embodiment 2

[0072] A specific embodiment of the present invention is that the subgrade coefficient K of a high-speed railway embankment coarse-grained soil filler 30 Estimation method, its steps are as follows:

[0073] A. Determination of the maximum dry density of the filler sample

[0074] The maximum dry density ρ of the filler sample measured from the maximum dry density test of coarse-grained soil dmax ;

[0075] B. Determination of the maximum bite force of the filler sample under the control value K of the compaction coefficient

[0076] B1, prepare the shear test sample: according to the maximum dry density ρ of the filler sample obtained in step A dmax , The control value K of the filling compaction coefficient of the subgrade structure layer of the high-speed railway to be filled (the control value K of the filling compaction coefficient can be found in the "High-speed Railway Design Code" (Trial) TB10621-2009), and the dryness of the shear test sample is calculated Density...

Embodiment 3

[0082] A specific embodiment of the present invention is that the subgrade coefficient K of a high-speed railway embankment coarse-grained soil filler 30 Estimation method, its steps are as follows:

[0083] A. Determination of the maximum dry density of the filler sample

[0084] The maximum dry density ρ of the filler sample measured from the maximum dry density test of coarse-grained soil dmax ;

[0085] B. Determination of the maximum bite force of the filler sample under the control value K of the compaction coefficient

[0086] B1, prepare the shear test sample: according to the maximum dry density ρ of the filler sample obtained in step A dmax , The control value K of the filling compaction coefficient of the subgrade structure layer of the high-speed railway to be filled (the control value K of the filling compaction coefficient can be found in the "High-speed Railway Design Code" (Trial) TB10621-2009), and the dryness of the shear test sample is calculated Density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com