Coal mine drilling blowout preventer

A blowout prevention device and blowout prevention technology are applied in the field of devices for preventing water or gas in the coal seam from blowing out by drilling in underground coal mines. Reasonable, strong acid and alkali resistance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

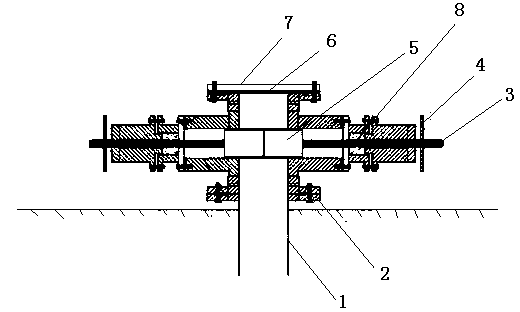

[0027] Such as figure 1 The blowout prevention device for coal mine drilling shown includes an orifice casing 1, the top of the orifice casing 1 is fixedly connected with a blowout prevention ram 5 through a flange 2, and the two ends of the blowout prevention ram 5 pass through a screw rod 3 Two symmetrical wheels 4 are connected, and the outer periphery of the blowout ram 5 is provided with a sealing ring 8; the upper end of the blowout ram 5 is provided with a blowout pad 6, and above the blowout pad 6 is provided with a fastening pad 6 Gland7.

[0028]

Embodiment 2

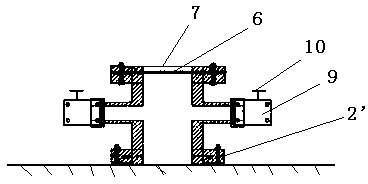

[0030] Such as figure 2 The blowout prevention device for coal mine drilling shown includes an orifice casing, and two discharge pipes 9 are symmetrically arranged on both sides of the orifice casing, and a valve 10 is provided on the discharge pipe 9, and a blowout prevention pad 6 is provided at the upper end of the discharge pipe 9 , The top of the blowout-proof pad 6 is provided with the gland 7 for fastening the blowout-proof pad 6, and the device is fixed at the orifice through the flange 2' for gas or water blowout prevention.

[0031]

Embodiment 3

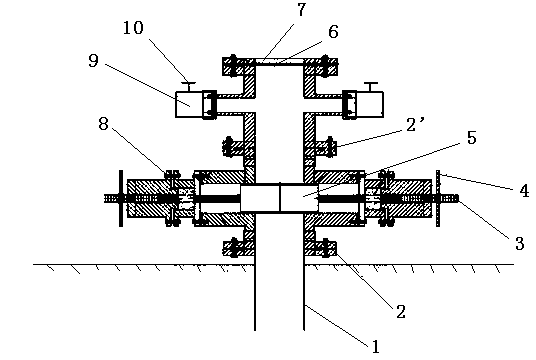

[0033] Such as image 3 The blowout prevention device for coal mine drilling shown includes an orifice casing 1, the top of the orifice casing 1 is fixedly connected with a blowout prevention ram 5 through a flange 2, and the two ends of the blowout prevention ram 5 pass through a screw rod 3 Two symmetrical wheels 4 are connected, and a sealing ring 8 is provided on the outer periphery of the blowout ram 5; two symmetrical drain pipes 9 are arranged on the upper end of the blowout ram 5, and a valve 10 is arranged on the drain pipe 9, and the drain pipe 9 It is fixedly connected with the blowout ram 5 through the flange 2', the upper end of the discharge pipe 9 is provided with a blowout pad 6, and the top of the blowout pad 6 is provided with a gland 7 for fastening the blowout pad 6.

[0034] The present invention has two upper and lower blowout prevention facilities, the first one is the gate-to-card type blowout prevention, and the second one is the pressure relief blocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com