Motor vehicle headlamp assembly and motor vehicle with same

A technology for motor vehicles and headlights. It is applied in the field of motor vehicles. It can solve problems such as easy flow dead angles, failure to increase the temperature of flow dead angles, and inability to completely solve the problem of fogging, so as to prevent heat loss, reduce heat exchange, and suppress fog. generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

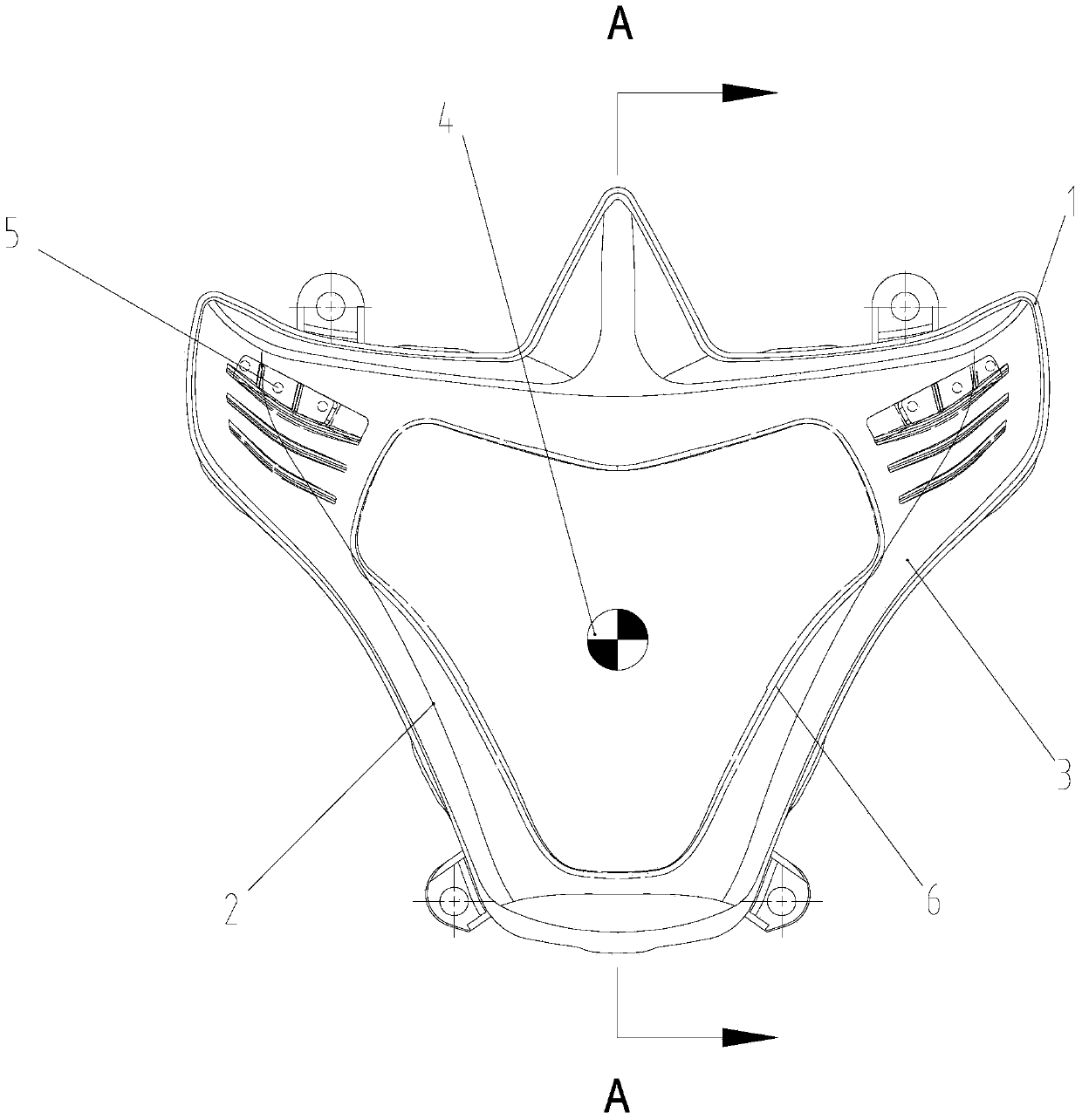

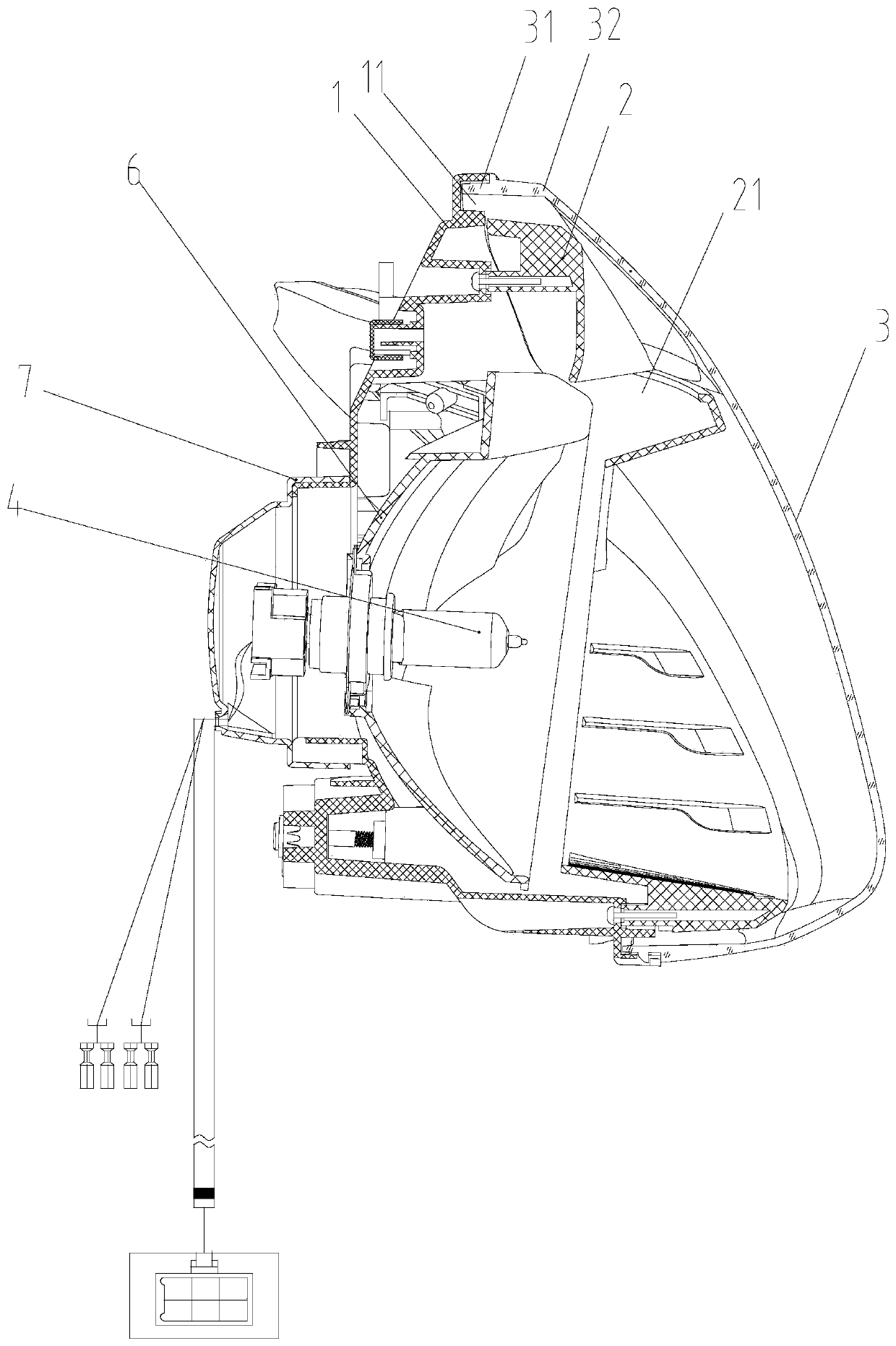

[0015] figure 1 is the front view of the present invention, figure 2 for figure 1 A-A cross-sectional view, as shown in the figure: the motor vehicle headlight assembly of the present invention includes a lamp housing 1, a decorative ring 2 and a light distribution mirror 3, and the decorative ring 2 and the light distribution mirror 3 are respectively connected with the lamp housing. 1 is connected, the decorative ring 2 is provided with a through hole, and the light emitted by the bulb 4 is irradiated to the inner peripheral side wall of the light distribution mirror 3 through the through hole 21; The headlights are the same in component configuration, connection relationship and function. In addition to the above components, they also have a reflector 6, a dust cap 7 and a number of ventilation holes; the inner peripheral side wall of the light distribution mirror 3 is assigned Around the inner surface of the light mirror 3, since this area is located outside the decorat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com