Anti-fogging toughened antibacterial cast polypropylene food packaging film and preparation method thereof

A technology of casting polypropylene and food packaging film, which is applied in the field of food packaging film, can solve the problems of unsatisfactory anti-fog effect, affecting film transparency, high production cost, etc., and achieve good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

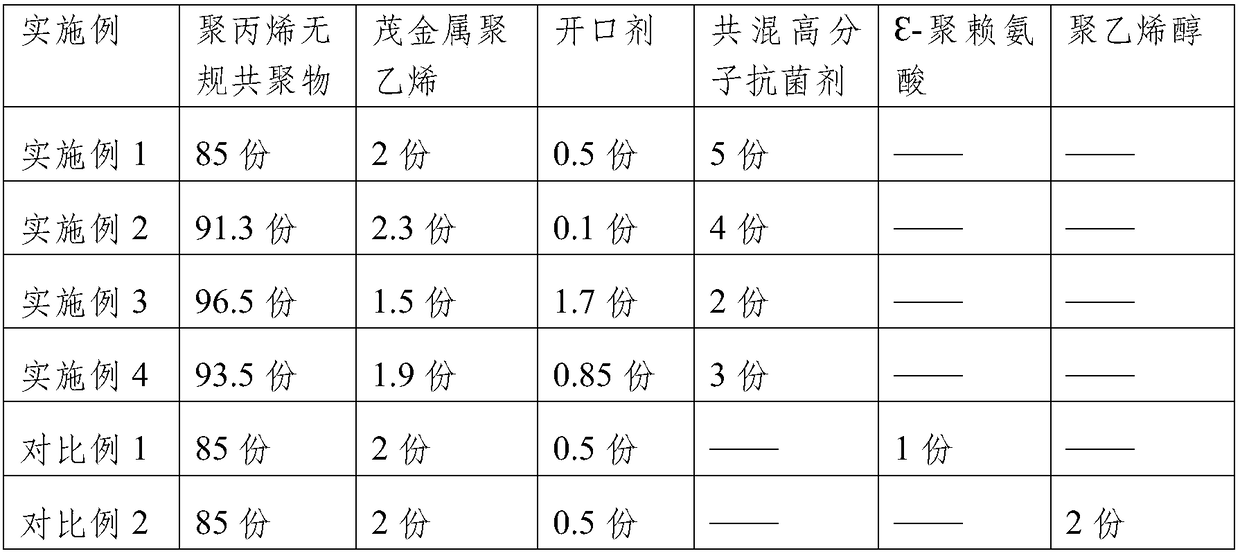

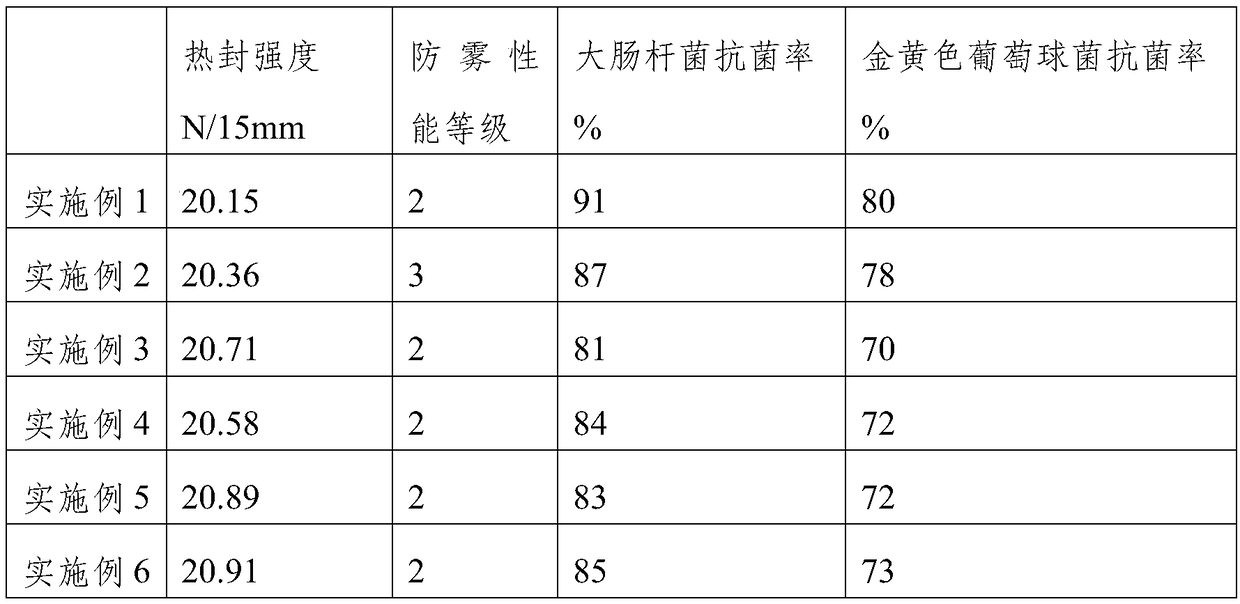

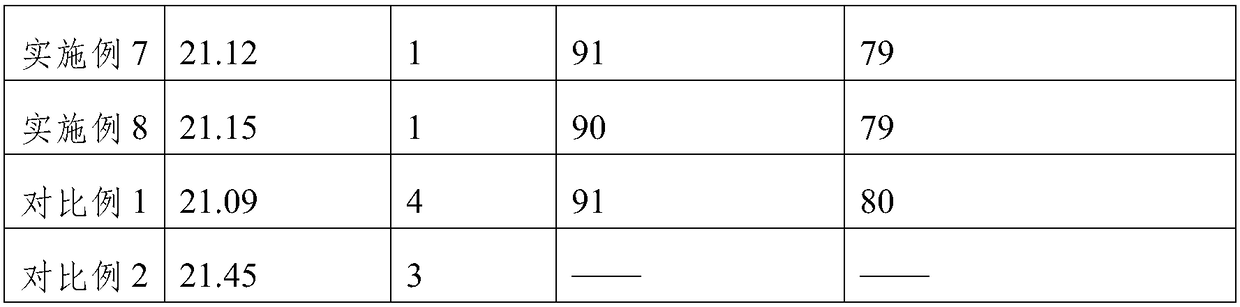

Examples

Embodiment 1

[0033] Example 1 The preparation steps of the blended polymer antimicrobial agent containing ε-polylysine: dissolve the plasticizer, polyvinyl alcohol and polylysine in water, stir evenly, heat to 50°C, and keep warm until a transparent Homogeneous solution, dry, obtain the blending macromolecule antibacterial agent containing ε-polylysine; The ratio of the mass concentration of glycerol in the reaction system and the mass concentration of ε-polylysine is 1.5:1; The raw material composition of core layer It is homopolypropylene and a smooth agent, the parts by weight of the smooth agent in 100 parts of the core material are 0.5-1.5 parts, and the smooth agent is erucamide.

[0034] The raw material composition of the corona layer includes homopolypropylene, an anti-oxidant and an antioxidant, and 100 parts of the corona layer raw material contains 0.5-2 parts of the anti-oxidant and 0.05-0.3 parts of an anti-oxidant.

[0035] Among the embodiment 1, the plasticizer adopts glyc...

Embodiment 2

[0036] The polypropylene random copolymer model of embodiment 2 is W0723F of Dushanzi Petrochemical Company, the polypropylene random copolymer model of embodiment 3 is F800E of Shanghai Petrochemical, and the polypropylene random copolymer model of embodiment 4 is FL7540 of Singapore TPC; In Example 2-4, the degree of polymerization of ε-polylysine is 30-35, and the degree of polymerization of polyvinyl alcohol is 1200-1700; the blending ratio of ε-polylysine and polyvinyl alcohol is 1:1.5 .

Embodiment 5-6

[0038] The difference between Examples 5-6 and Example 4 is that the blending ratios of ε-polylysine and polyvinyl alcohol are 1:3 and 1:2.2, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com