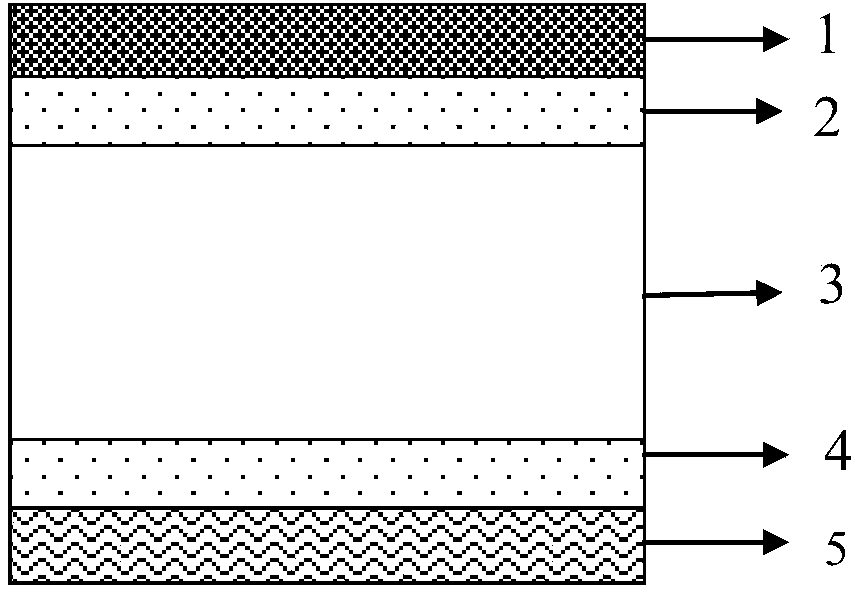

Biaxially-oriented polypropylene anti-mist film with five-layer coextrusion and manufacturing method thereof

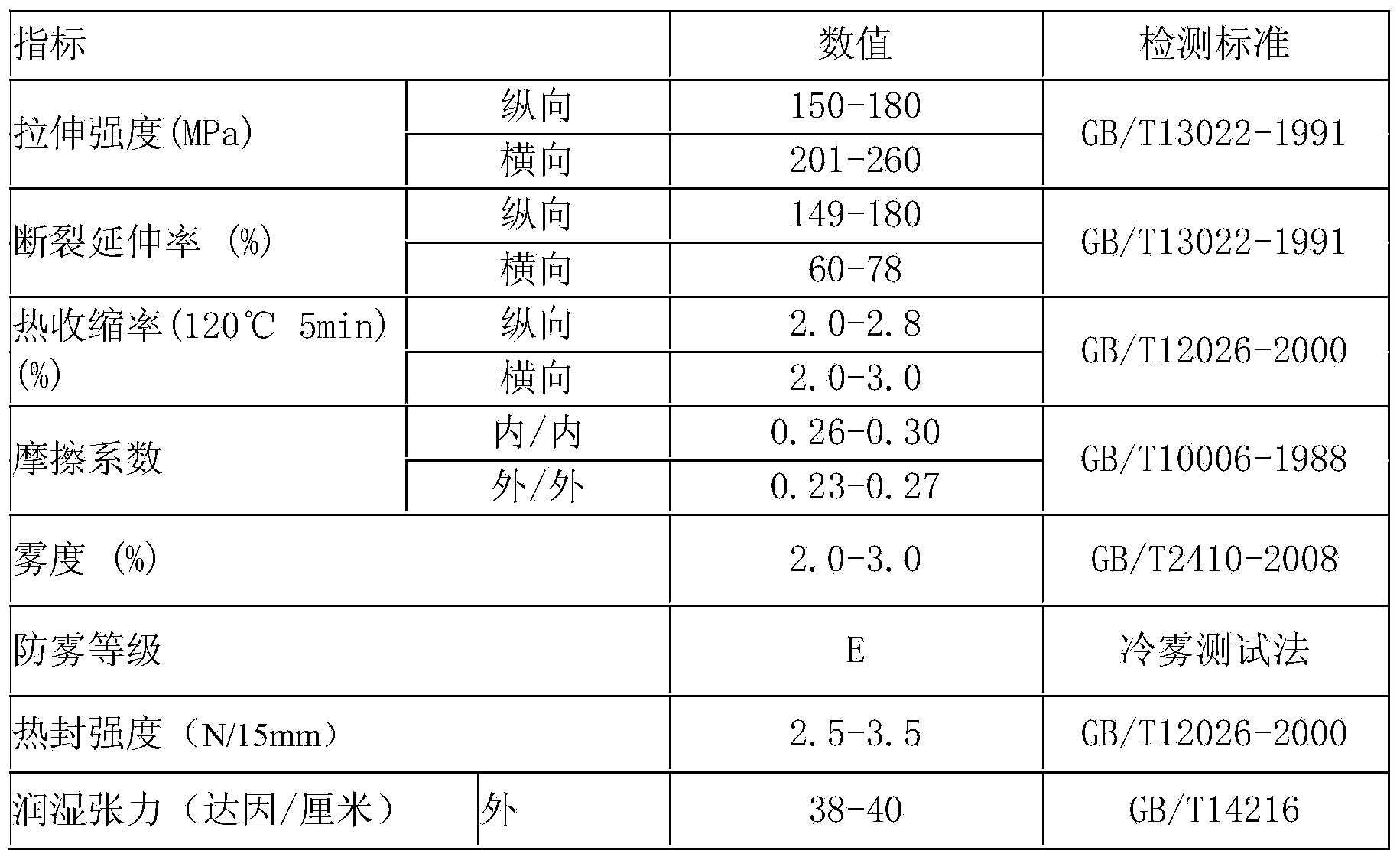

A biaxially stretched and copolymerized polypropylene technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. The effect of high printability, excellent anti-fog function, and excellent anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Ingredients: Produce a film with a thickness of 17 μm. The thickness of the upper layer is 0.8 μm, in which the content of copolymerized polypropylene is 97.5%, polyglycerol fatty acid ester is 1.5%, and synthetic silica is 1%; the thickness of the upper layer is 0.5 μm, and polyglycerin fatty acid ester is 100%; Polypropylene 99.5%, polyglycerin fatty acid ester 0.5%; the thickness of the next layer is 0.5μm, polyglycerol fatty acid ester 100%; the thickness of the lower layer is 0.8μm, wherein the content of copolymerized polypropylene is 97.5%, polyglycerol fatty acid ester 1.5% , Synthetic silica 1%.

[0038] Film making: The biaxially oriented polypropylene anti-fog film of the present invention is produced by co-extrusion biaxially stretching process, wherein the temperature of the upper layer extruder: 190°C, the temperature of the upper layer extruder: 220°C, and the temperature of the middle layer extruder : 230°C, next layer extruder temperature: 220°C, lower...

Embodiment 2

[0041] Ingredients: Produce a film with a thickness of 20 μm. The thickness of the upper layer is 0.8 μm, in which the content of copolymerized polypropylene is 96%, polyglycerin fatty acid ester is 3%, and synthetic silica is 1%; the thickness of the upper layer is 1 μm, and polyglycerin fatty acid ester is 100%; 97% propylene, 3% polyglycerol fatty acid ester; the thickness of the next layer is 1 μm, 100% polyglycerol fatty acid ester; the thickness of the lower layer is 1.2 μm, and the content of copolymerized polypropylene is 96%, 2% polyglycerol fatty acid ester, synthetic silica 2%.

[0042]Film making: The biaxially oriented polypropylene of the present invention is produced by co-extrusion biaxial stretching process, wherein the temperature of the upper layer extruder: 185°C, the temperature of the upper layer extruder: 210°C, and the temperature of the middle layer extruder: 230°C , the temperature of the next extruder: 210°C, the temperature of the lower extruder: 1...

Embodiment 3

[0045] Ingredients: Produce a film with a thickness of 22 μm. The thickness of the upper layer is 1.5 μm, and the content of copolymerized polypropylene is 97%, polyglycerol fatty acid ester is 2.0%, and synthetic silica is 1%. The thickness of the last layer is 1.5 μm, and polyglycerin fatty acid ester is 100%. Polypropylene 98%, polyglycerol fatty acid ester 2%; the next layer thickness 1.5μm, polyglycerol fatty acid ester 100%; lower layer thickness 1.5μm, in which the content of copolymerized polypropylene is 95%, polyglycerol fatty acid ester 3% , Synthetic silica 2%.

[0046] Film making: The biaxially oriented polypropylene anti-fog film of the present invention is produced by co-extrusion biaxially stretching process, wherein the temperature of the upper layer extruder: 200°C, the temperature of the upper layer extruder: 220°C, and the temperature of the middle layer extruder : 235°C, next layer extruder temperature: 220°C, lower layer extruder temperature: 200°C; cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| preheating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com