Welding controller for welding equipment, welding equipment, and welding method for adjusting quality of generated welded joint

A technology of welding equipment and welding connection, which is applied in the direction of welding equipment, welding/welding/cutting items, resistance welding equipment, etc., can solve the problems of time consumption and high cost, and achieve the effect of large time advantage and cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

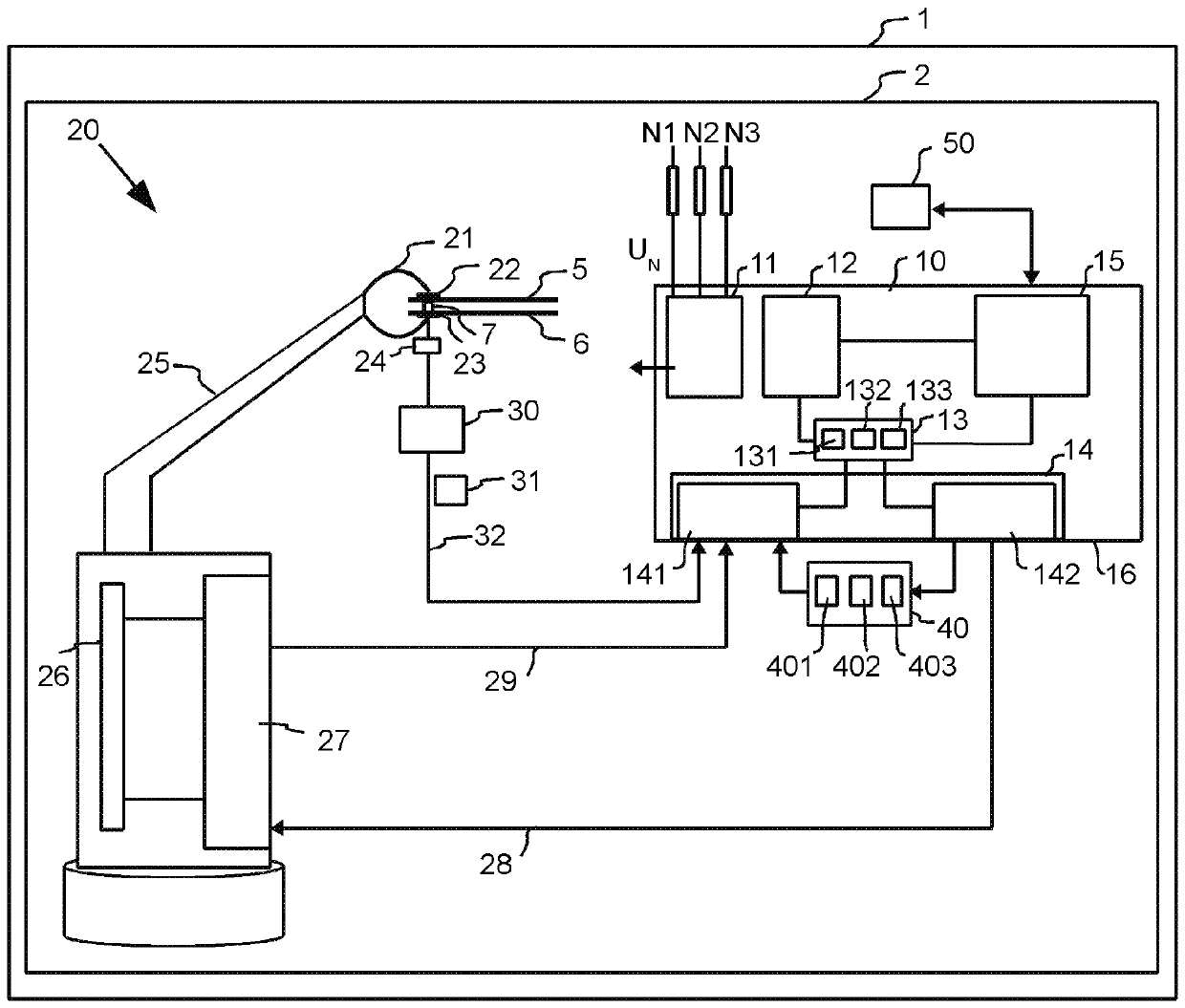

[0030] figure 1 An industrial plant 1 with a welding device 2 is shown. The industrial plant 1 is, for example, a production line for vehicles, furniture, buildings, etc., in which metallic workpieces 5 , 6 are joined by welding such that a welded connection 7 is produced. In particular, however, the welded connection 7 can thus also be produced only on the workpiece 5 by connecting the two edges of the workpiece 5 to one another by means of the welded connection 7 . The workpieces 5, 6 can be selected from any weldable material, such as steel, aluminum, alloys thereof, and the like. Here, various materials can be combined arbitrarily.

[0031] The welding device 2 has a welding controller 10 , a device 20 for guiding the welding tool 21 , a detection mechanism 30 , an operating device 40 and a superordinate control device 50 which can control the welding device 2 and / or the industrial system 1 other components not shown. Such components are, for example, a transport mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com