Use method of dust coagulation device based on gas atomization vortex fluid generation unit group

A generation unit and aerosolization technology, applied in chemical instruments and methods, safety devices, separation methods, etc., can solve the problem of gradient difference between surface tensions, etc., achieve strong self-containment ability, efficient dust condensation process, Implement effects with large spatial and temporal interval scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

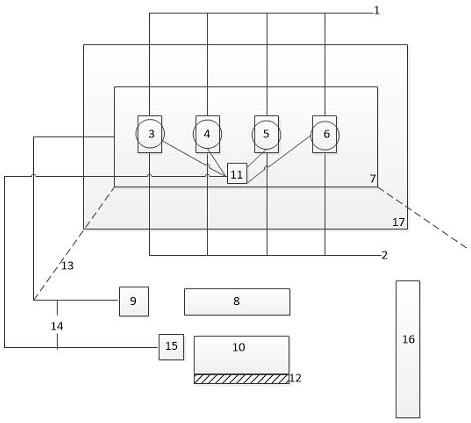

[0041] The device consists of pressure water circuit 1, pressure gas circuit 2, gas atomization vortex fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, gas atomization vortex Fluid generator D 6, aerosolized vortex fluid penetration angle regulator 7, tiny water droplet nuclei 8, tiny water droplet nucleation generation state observer 9, frustration process 10, vortex fluid outlet temperature fine-tuning device 11, surface tension gradient Poor process 12, dust generation control space 13, feedback control signal line 14, gas atomization vortex fluid condensation feedback device 15, gas atomization vortex group fluid 16, aerosol generation unit combination group 17, gas atomization vortex Swirl fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, and gas atomization vortex fluid generator D 6 are respectively provided with pressure gas pressure water on both sides...

Embodiment approach 2

[0050] The device consists of pressure water circuit 1, pressure gas circuit 2, gas atomization vortex fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, gas atomization vortex Fluid generator D 6, aerosolized vortex fluid penetration angle regulator 7, tiny water droplet nuclei 8, tiny water droplet nucleation generation state observer 9, frustration process 10, vortex fluid outlet temperature fine-tuning device 11, surface tension gradient Poor process 12, dust generation control space 13, feedback control signal line 14, gas atomization vortex fluid condensation feedback device 15, gas atomization vortex group fluid 16, aerosol generation unit combination group 17, gas atomization vortex Swirl fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, and gas atomization vortex fluid generator D 6 are respectively provided with pressure gas pressure water on both sides...

Embodiment approach 3

[0059] The device consists of pressure water circuit 1, pressure gas circuit 2, gas atomization vortex fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, gas atomization vortex Fluid generator D 6, aerosolized vortex fluid penetration angle regulator 7, tiny water droplet nuclei 8, tiny water droplet nucleation generation state observer 9, frustration process 10, vortex fluid outlet temperature fine-tuning device 11, surface tension gradient Poor process 12, dust generation control space 13, feedback control signal line 14, gas atomization vortex fluid condensation feedback device 15, gas atomization vortex group fluid 16, aerosol generation unit combination group 17, gas atomization vortex Swirl fluid generator A 3, gas atomization vortex fluid generator B 4, gas atomization vortex fluid generator C 5, and gas atomization vortex fluid generator D 6 are respectively provided with pressure gas pressure water on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com