Electric heating device

An electric heating device and electric heating rod technology, applied in electric heating devices, ohmic resistance heating, water heaters, etc., can solve the problems of poor heat conversion efficiency, large energy consumption, waste of energy, etc., to reduce maintenance costs and achieve optimal heat conversion. Efficiency, effect of fast temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

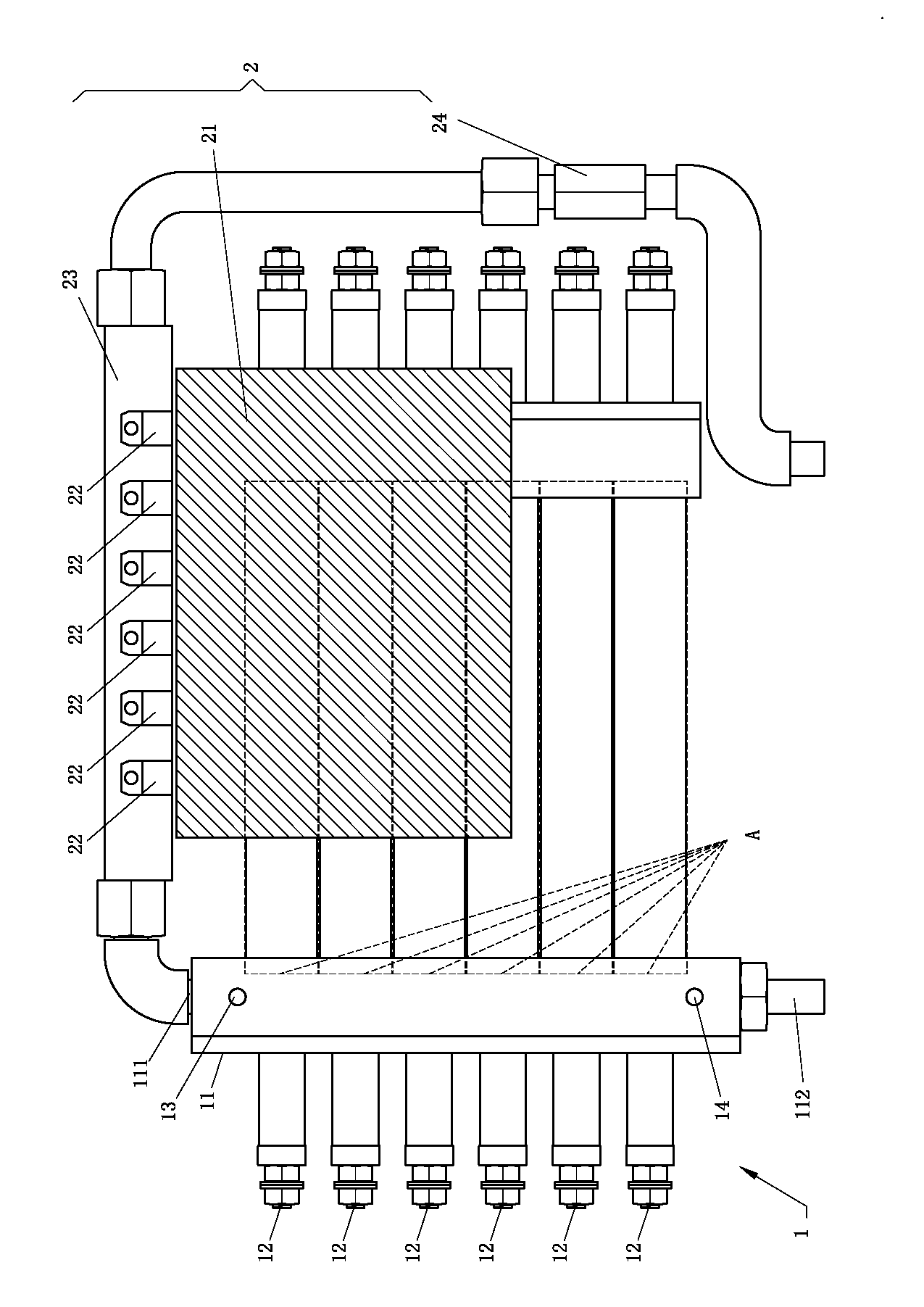

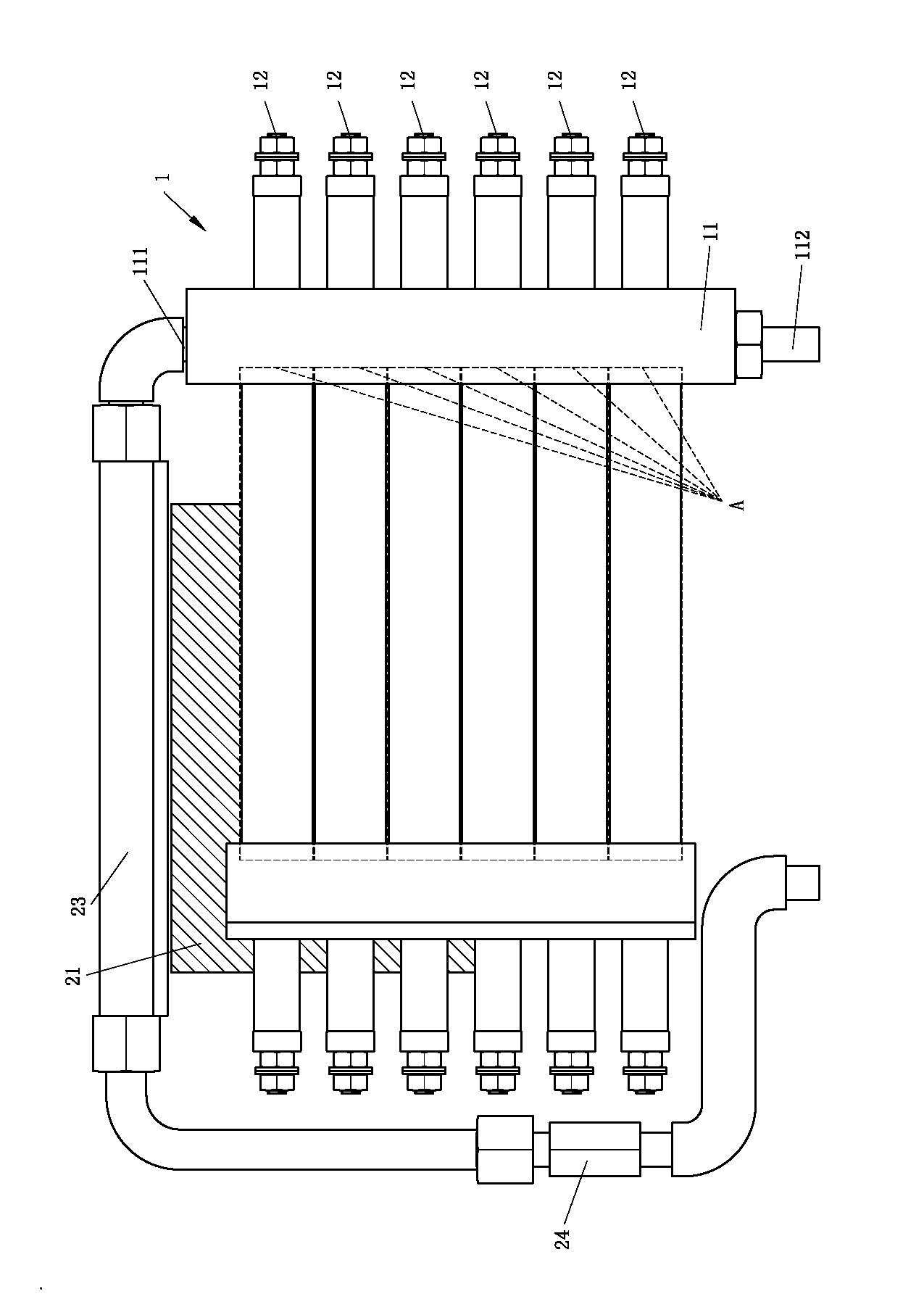

[0041] First, see figure 1 and figure 2 As shown, the preferred embodiment of the present invention is an electric heating device, comprising:

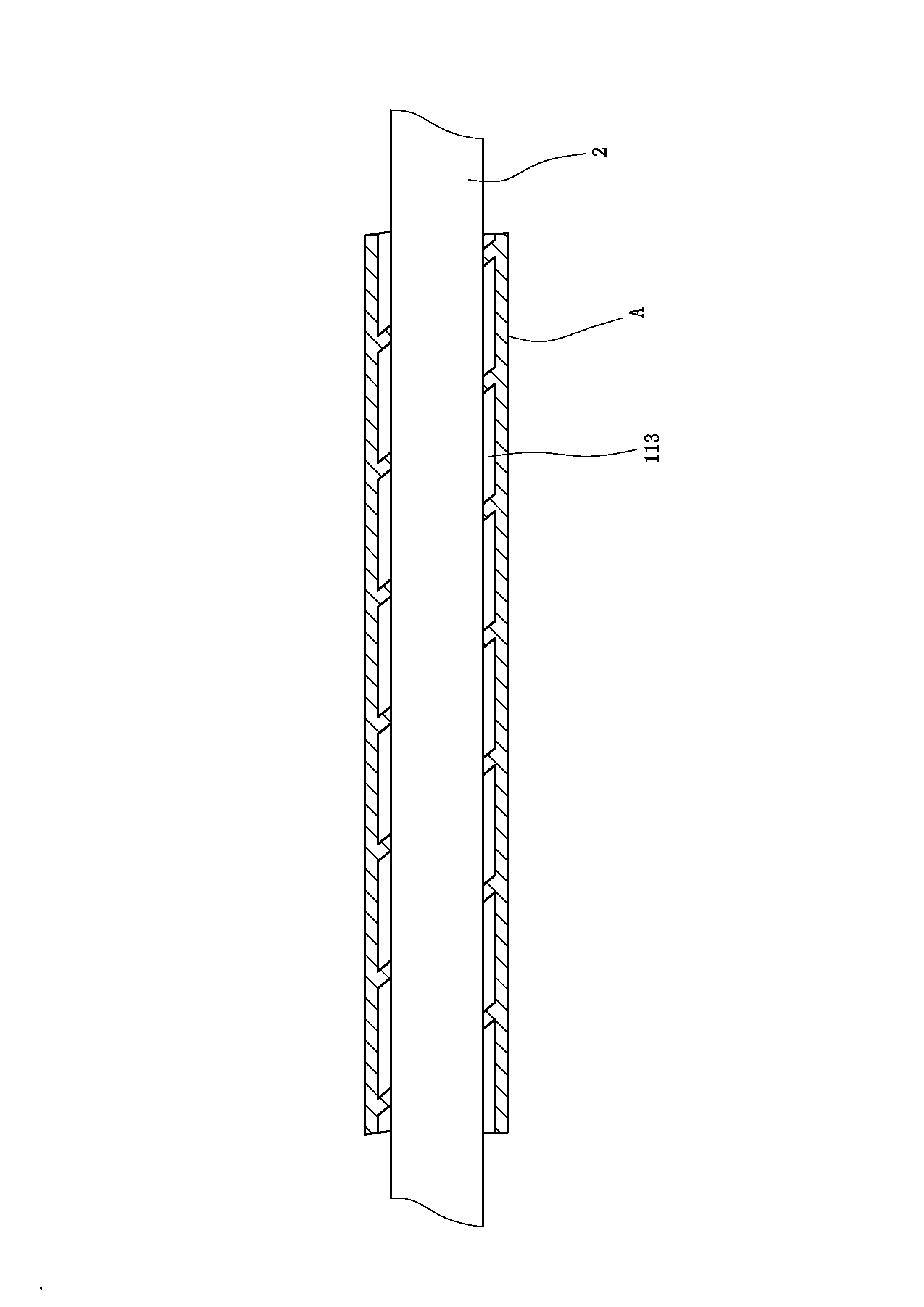

[0042] A heating unit 1 includes a liquid pipeline 11 used as a heating flow channel for the liquid, the aforementioned liquid pipeline 11 is provided with an inlet 111 and an outlet 112, so that the liquid can enter the aforementioned liquid pipeline 11 from the aforementioned inlet 111, and undergo a heating process While flowing out from the outlet 112, the inlet 111 and the outlet 112 of the liquid pipeline 11 are divided into a plurality of heating sections A, and each heating section A houses an electric heating rod 12 respectively, and the aforementioned electric heating rod 12 is used for Supply heat energy to the liquid flowing through the heating section A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com