Thickness meter

A technology of film thickness meter and film thickness, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of affecting the measurement results, lowering the measurement accuracy, and reducing the light intensity of the optical path transmission, and it is difficult to achieve the measurement results and the measurement accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

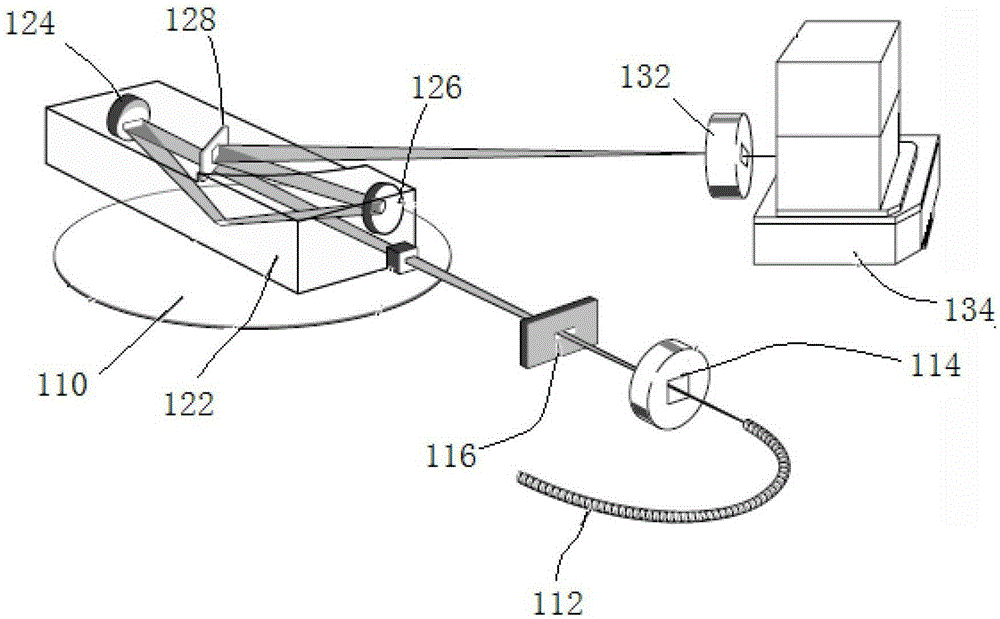

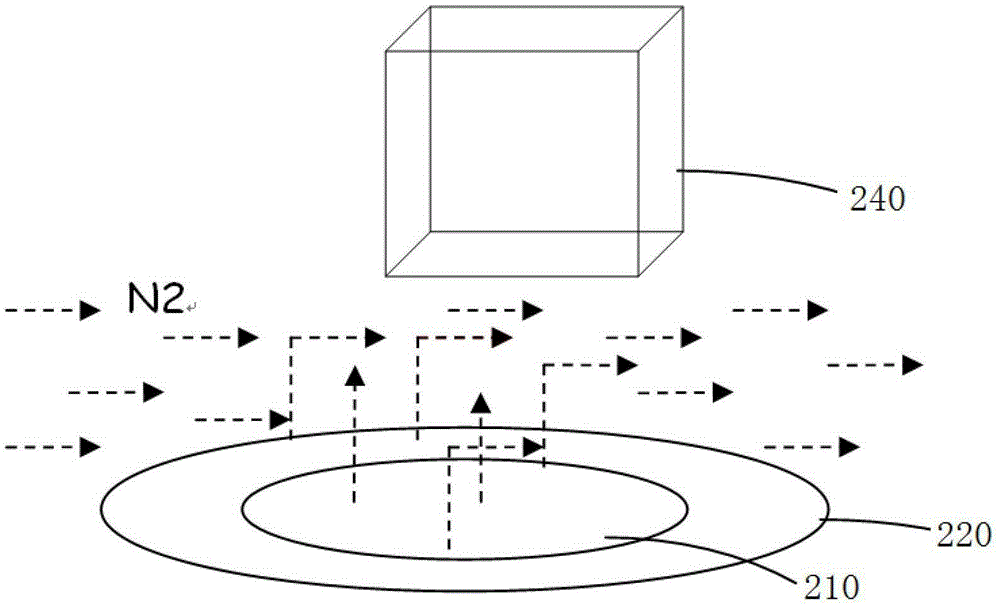

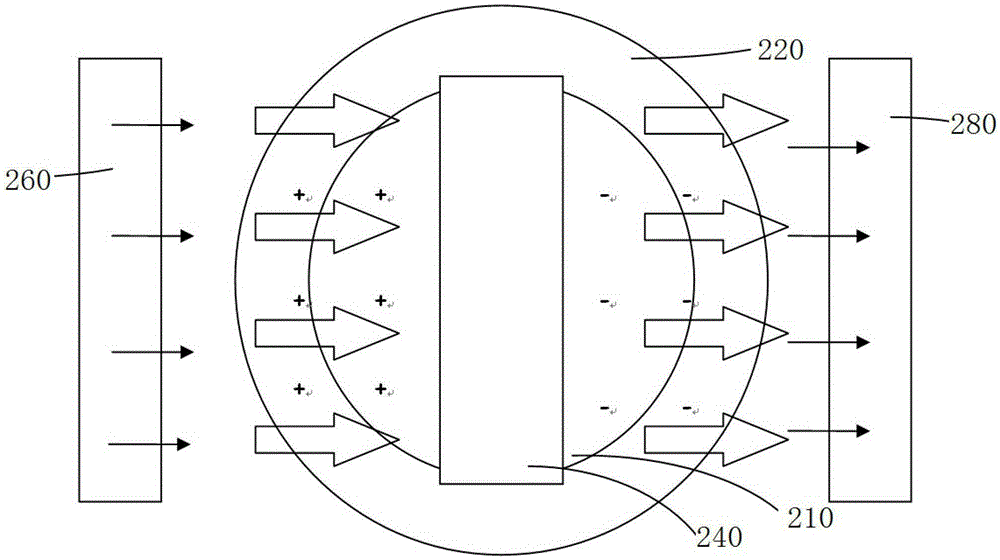

[0019] Please refer to figure 2 In one embodiment, a film thickness meter for measuring the thickness of a film on a wafer 210 is provided, the film thickness meter includes a measuring beam generator for generating a measuring beam, an optical system, a processing device and a carrying measuring beam generator, An optical system, a carrying frame of the processing device, the optical system transmits the measuring beam generated by the measuring beam generator to the film on the wafer 210, and transmits the measuring beam reflected by the film on the wafer 210 to the processing device, The processing device calculates the thickness of the film on the wafer 210 after processing the light beam from the optical system. The carrier frame is provided with a wafer carrier 220, the optical system includes a light beam adjustment box 240, the beam adjustment box 240 is arranged on the top of the wafer carrier 220 and forms a gap with the wafer carrier 220, the wafer carrier A gas f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com