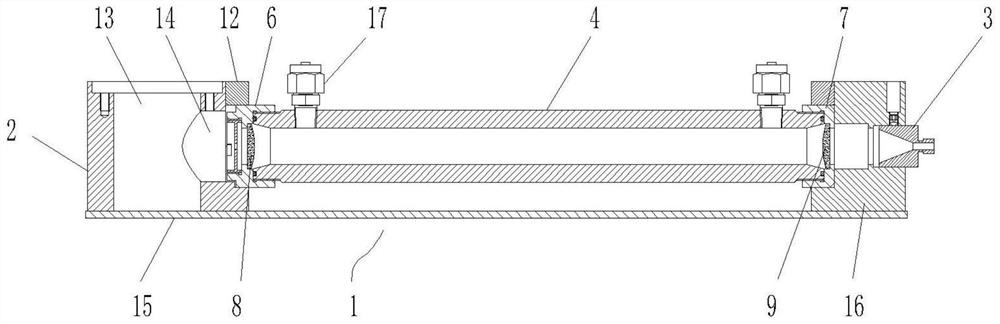

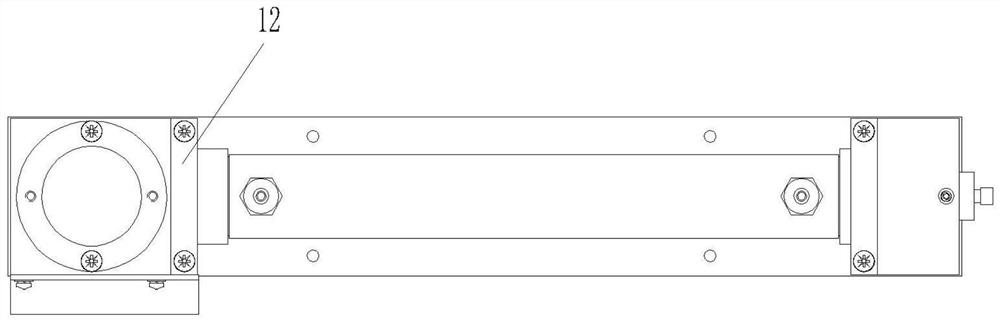

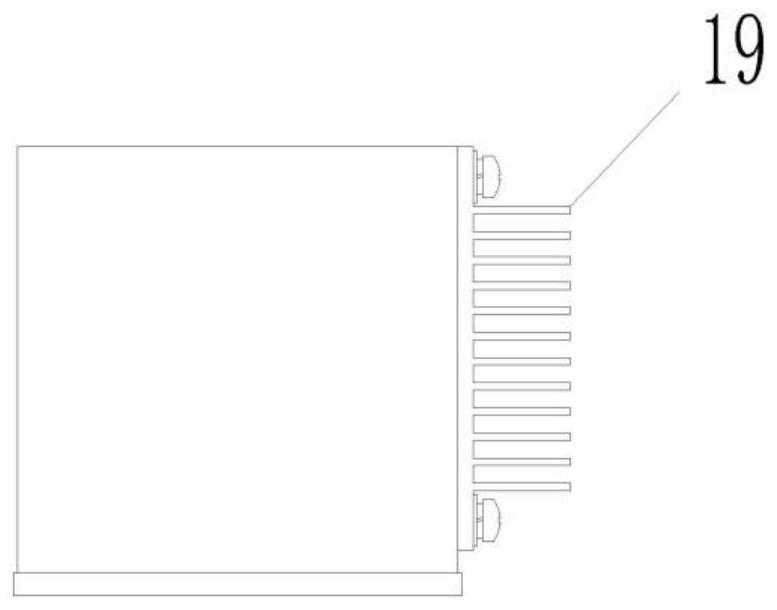

Ultraviolet absorption air chamber assembly

An external absorption and air chamber technology, applied in the field of ultraviolet absorption air chamber assembly, can solve the problems of complicated disassembly of the air chamber, difficult cleaning, etc., and achieve the effects of reducing cost, simple disassembly process and good beam shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The ultraviolet absorption gas chamber assembly is used in ultraviolet absorption gas analyzers, which are mostly used for flue gas emission monitoring, so they are also called flue gas analyzers. The core structural components of existing analyzers mainly include light sources, ultraviolet absorption gas chambers Assembly, optical fiber and spectrometer, the optical path structure is that the ultraviolet light emitted by the light source enters the gas chamber through the optical fiber, then the ultraviolet light passes through the gas chamber and then transmits to the optical fiber, and finally enters the spectrometer through the optical fiber connection for analysis; the gas chamber is mainly the gas to be measured. And the part that absorbs the ultraviolet light; because the ultraviolet light emitted by the light source enters the gas chamber through the optical fiber, the optical fiber is generally an ultraviolet-resistant optical fiber, and the degree of bending als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com