Harmful gas sampling method for automotive interior parts

A technology for harmful gases and automotive interiors, applied in the direction of sampling devices, etc., can solve the problem of inability to provide effective guidance for the rectification of the air quality in the vehicle, it is difficult to predict the contribution of the air quality of a single component in the vehicle, and it is impossible to form complex components Sampling and other issues to avoid large differences in test data, stable test data, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

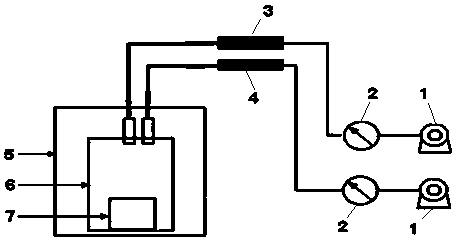

[0021] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

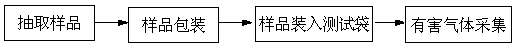

[0022] see figure 1 As shown, the harmful gas sampling method of automotive interior parts includes the following steps:

[0023] First, take samples: take overall sampling for the automotive interior components assembly, and take test samples from the qualified automotive interior components to ensure that the status and details of the components are consistent with the mass-produced vehicles. Considering that the sample may absorb volatile organic substances that do not belong to itself from the surrounding environment, the time from the completion of sample production to sampling shall not exceed three days. When collecting samples, do not directly touch the sample with fingers or process the sample with a cutting saw that can generate heat (such as a high-speed rotary saw). Clean cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com