Test system and test method for measuring AC-LED junction temperature

A technology of AC-LED and test system, applied in the direction of single semiconductor device test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A Test System for Measuring AC-LED Junction Temperature

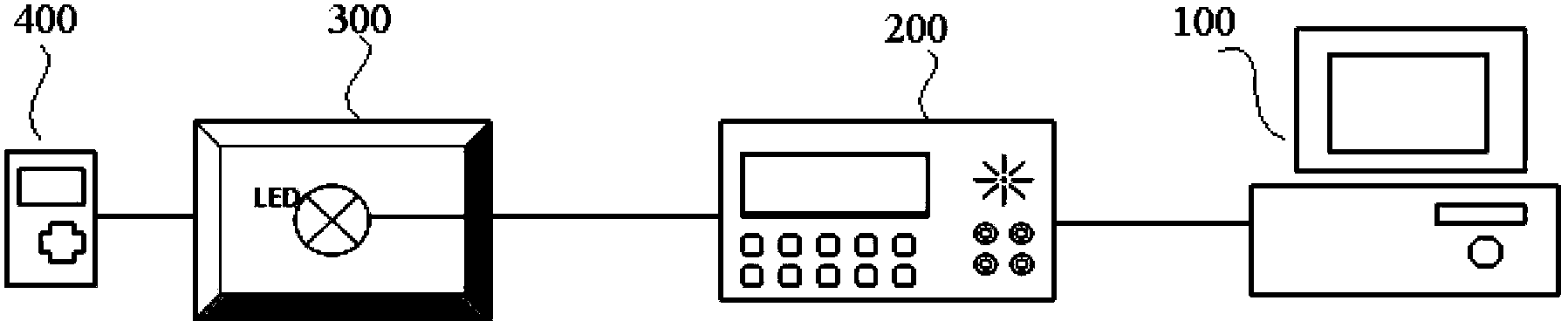

[0030] figure 1 It is a structural schematic diagram of the present invention, such as figure 1 As shown, a test system for measuring the AC-LED junction temperature includes: a computer 100 , a programmable pulse current source 200 , a constant temperature box 300 , and a thermometer 400 . The alternating current AC-LED is set in the constant temperature box 300 .

[0031] A test method for a test system for measuring the AC-LED junction temperature, comprising the following steps:

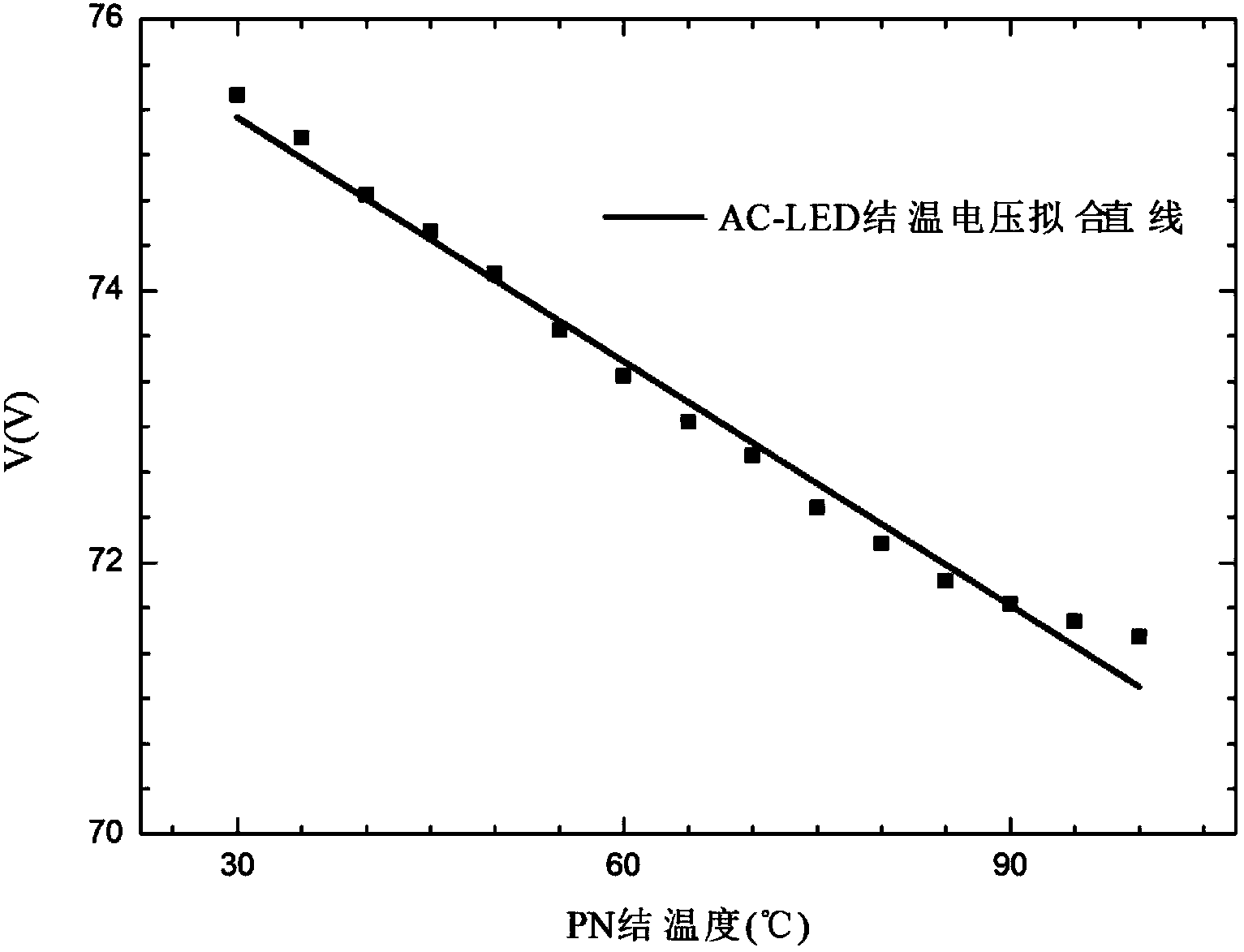

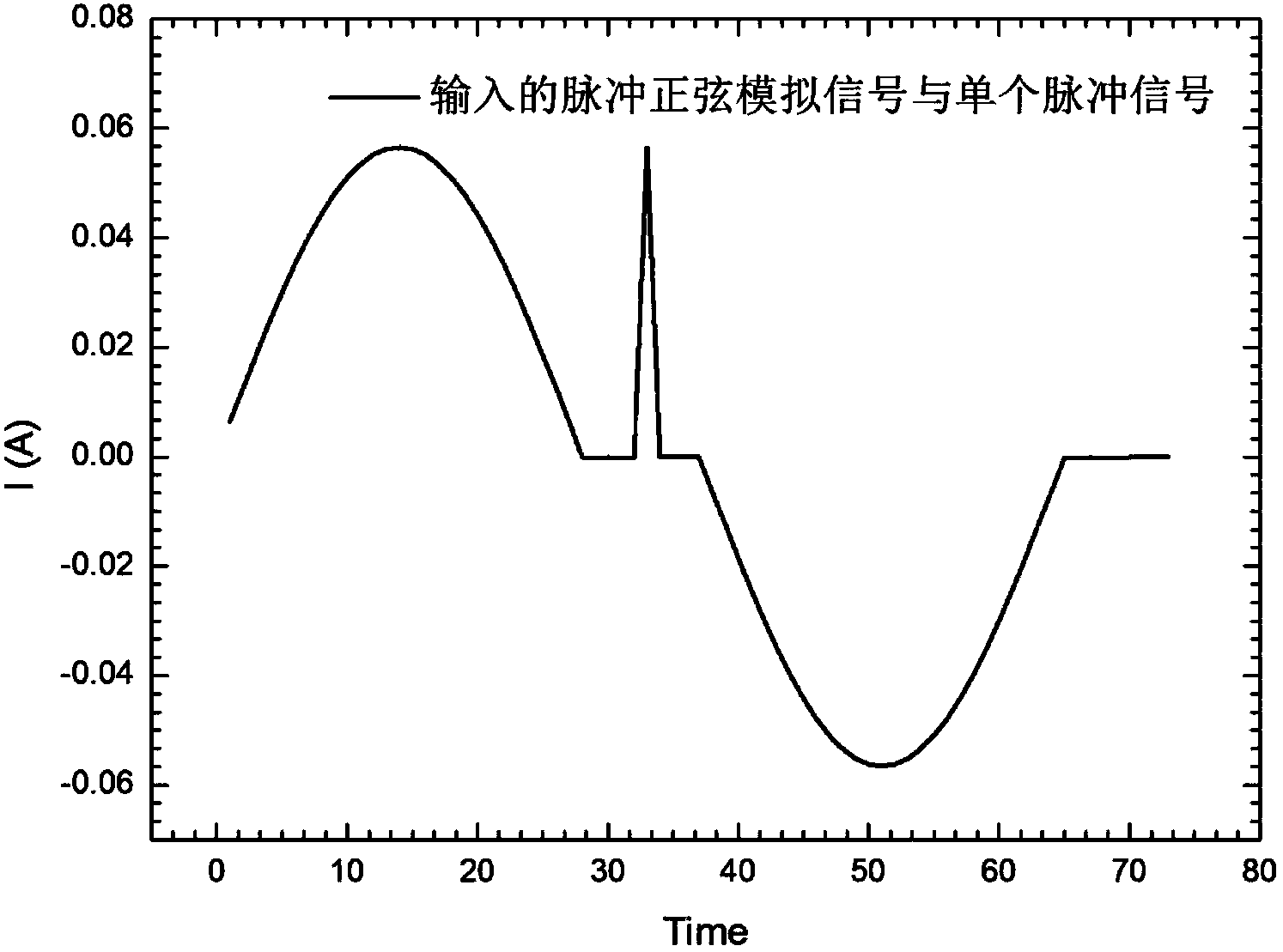

[0032] Similar to measuring the DC DC-LED junction temperature with the pulse method, a calibration process is first performed on the AC-LED to be tested. The AC-LED is heated at different temperatures. After the heat is balanced, the chip of the AC-LED is fully heated at this time, and the temperature of several chips in the AC-LED is the same. Approximately, the ambient temperature at this time can be regarded as the junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com