Structural topology-shape combined optimization method based on multi-arc-section curve under pressure load

A joint optimization and curve technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor practicability and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

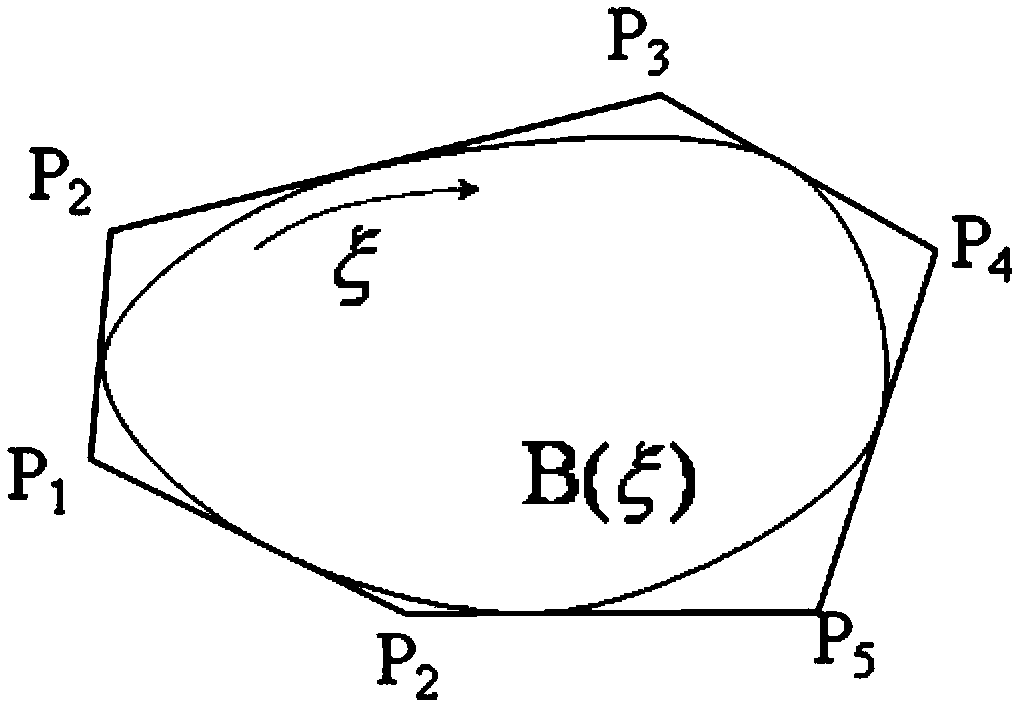

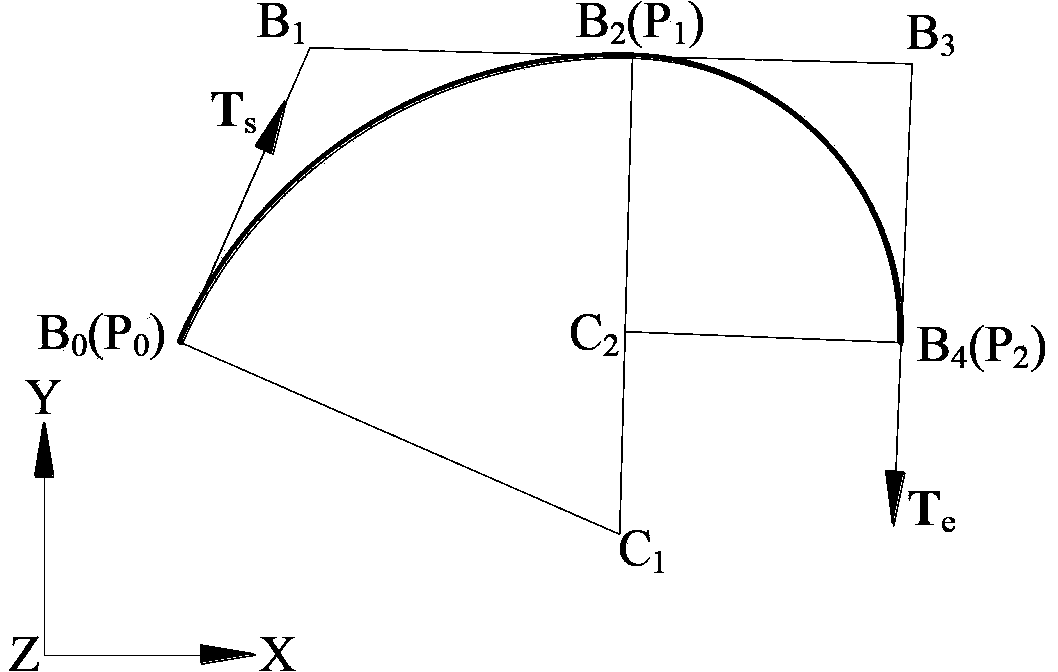

[0042] refer to Figure 3-7 . The structure topology-shape joint optimization method under pressure load based on multi-arc curves in the present invention specifically includes the following steps.

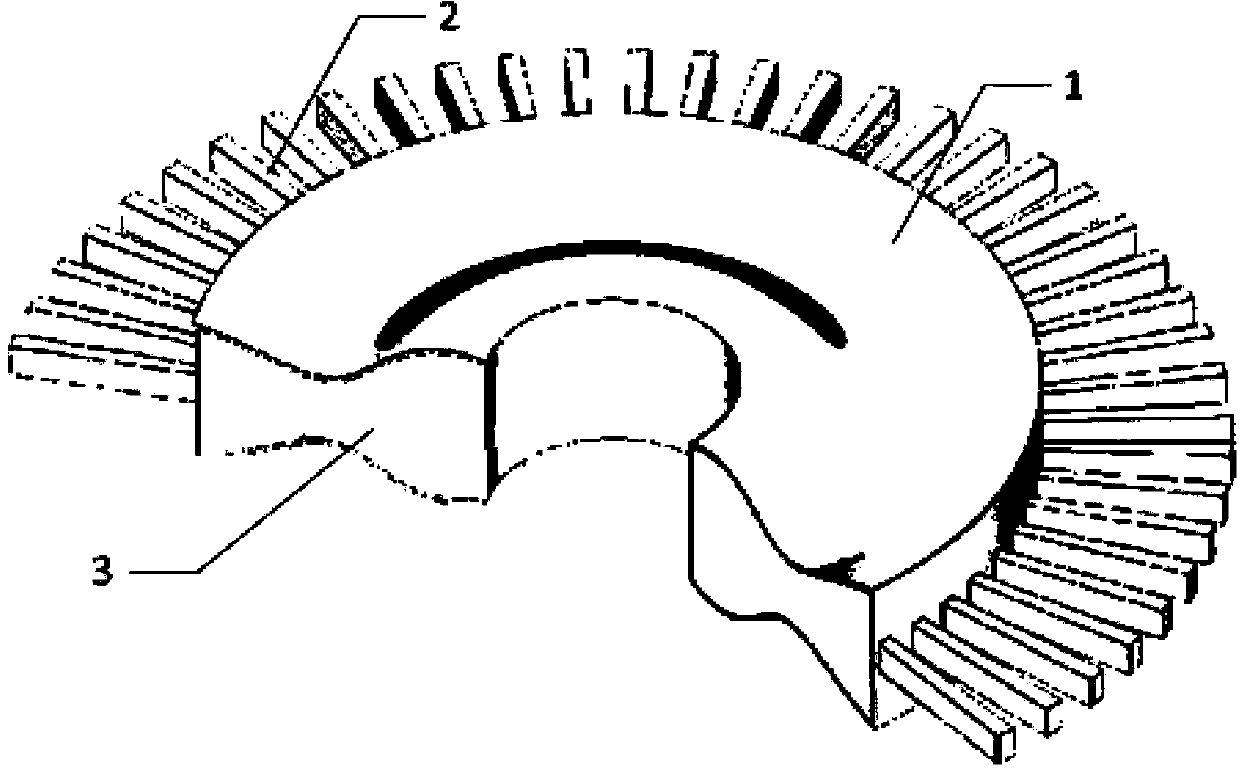

[0043] The present invention will be described below by taking the load-bearing frame of the engine as an example.

[0044]Engine load-bearing frame 1 is the key load-bearing component in the engine, which bears complex loads, including the air flow pressure difference between the front and rear of the stator blade 2 and the load-bearing frame cross section 3, the axial force and torque of the air flow on the blade, and the maneuvering process, etc. Among them, the airflow pressure difference between front and back is the key load it bears.

[0045] The load-bearing frame 1 of the engine is a revolving body of the central axis 6 of the load-bearing frame, and its interface size is that the design domain 4 of the cross-section of the load-bearing frame is up to 40 mm, the radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com