A storage material and its application in non-volatile charge-trap storage devices

A charge trapping, non-volatile technology, applied in the field of microelectronic materials, which can solve problems such as difficulty in meeting the requirements of memory miniaturization, polysilicon floating gate charge loss, leakage current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

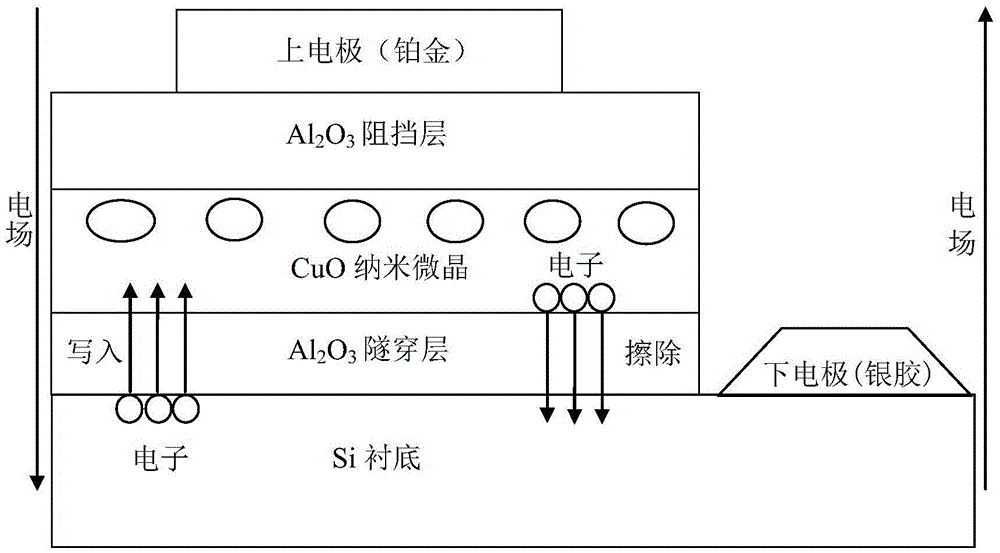

[0024] a) Use P-type Si as the substrate, and after cleaning, use ALD (vacuum atomic layer deposition or vacuum coating) technology to grow Al with a thickness of about 2-10nm on the surface 2 O 3 As a tunneling layer;

[0025] b) Using magnetron sputtering technology to grow uniform composition (CuO) on the tunnel layer X (Al 2 O 3 ) 1-x Thin film as storage layer;

[0026] c) Use ALD to grow another layer of Al about 15nm thick on the storage layer 2 O 3 As a barrier

[0027] d) Anneal the sample prepared above at a temperature lower than the melting point of CuO to make CuO nanocrystals precipitate out of the storage layer and be Al 2 O 3 Surrounded by amorphous matrix phase, the CuO nanocrystal is used as a storage medium; annealing is performed in a rapid annealing furnace, the annealing time is 20-60S, the annealing atmosphere is a nitrogen atmosphere, and the annealing temperature is 200±15°C; e) after annealing Magnetron sputtering was used to grow platinum with a thickness o...

Embodiment 2

[0028] Embodiment 2: Based on the Si substrate, the preparation process of the CuO nanocrystalline-based nonvolatile charge trapping memory device is specifically as follows:

[0029] a) Put the Si substrate in an appropriate amount of acetone, ultrasonically clean for 10 minutes, then use deionized water for ultrasonic cleaning for 10 minutes to remove the remaining substances on the substrate surface, and then put the substrate into the diluted hydrofluoric acid solution Soak in the medium for about 30 seconds to remove the surface oxides, and then use deionized water for ultrasonic cleaning for 5 minutes to wash off the residual hydrofluoric acid, dry it with high-purity nitrogen, and put it into the atomic layer chemical vapor deposition chamber to deposit the film.

[0030] b) Al(CH 3 ) 3 As the metal source, ozone is the oxygen source. Al deposited with a thickness of 3nm 2 O 3 As a tunneling layer.

[0031] c) Then put the sample into the magnetron sputtering growth chamber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com