Method for forming the battery case cover and battery explosion valve housing cap

A technology for battery shells and explosion-proof valves, which is applied in the direction of batteries, battery pack components, circuits, etc., can solve problems such as unstable pressure of explosion-proof valves, and achieve reliable cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

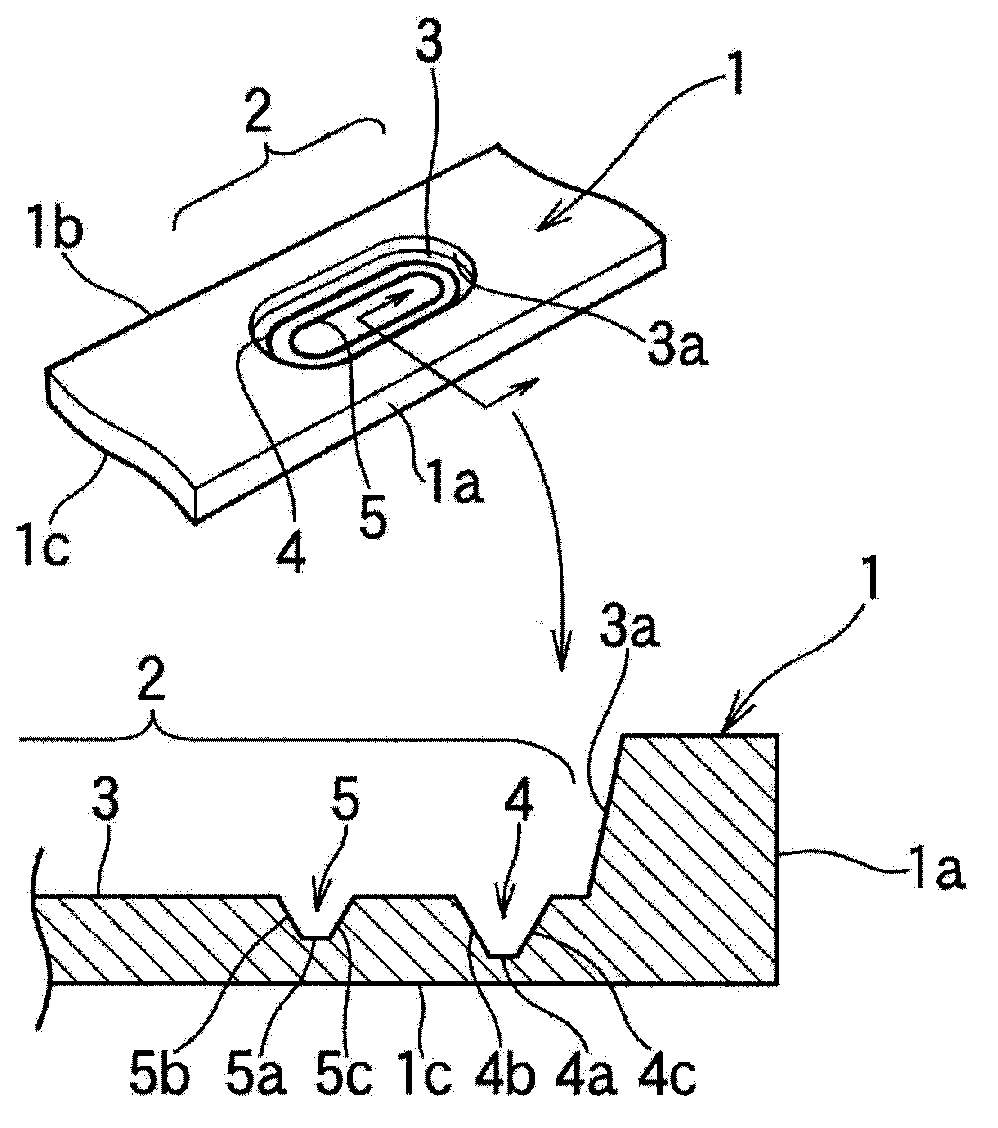

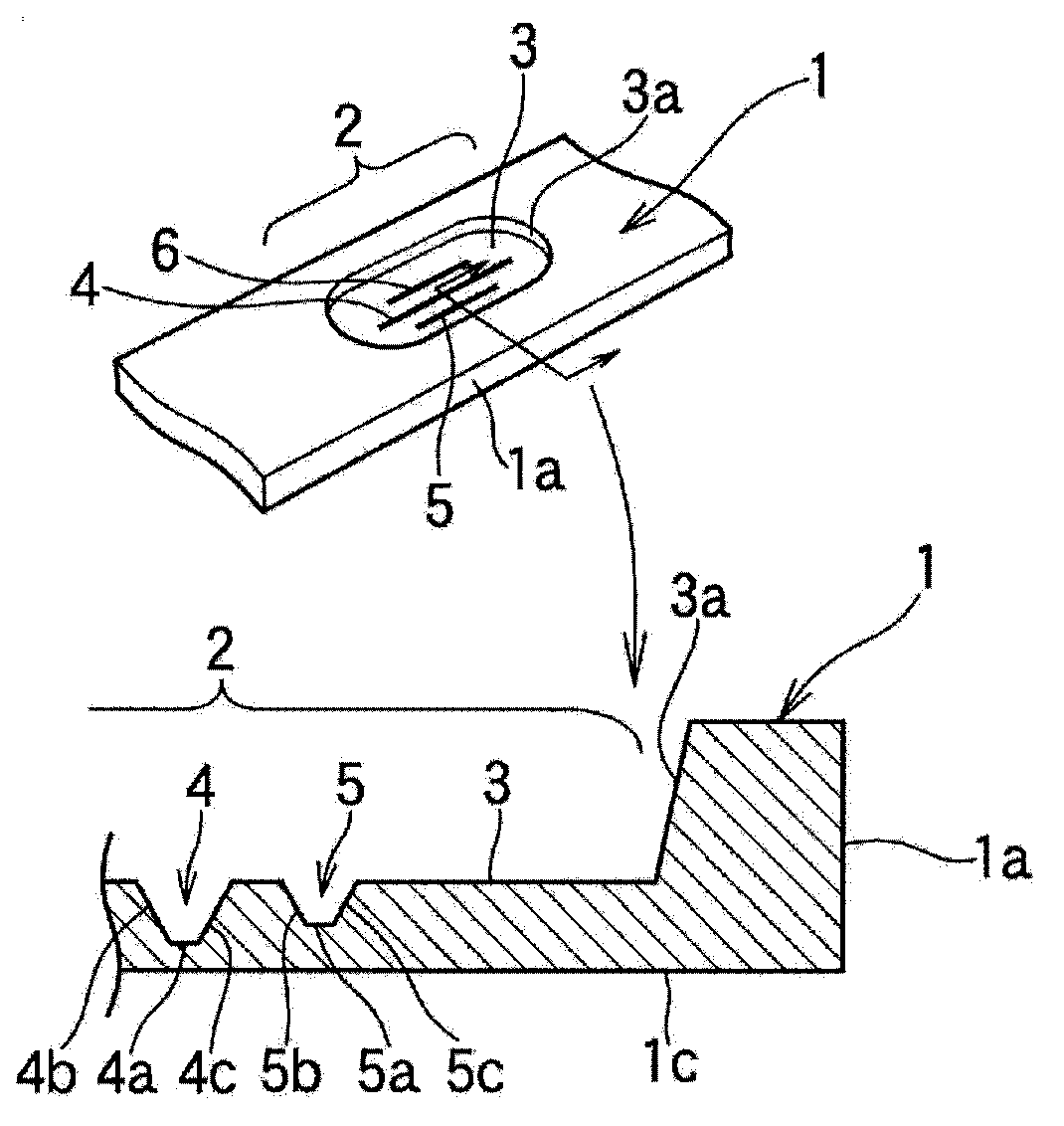

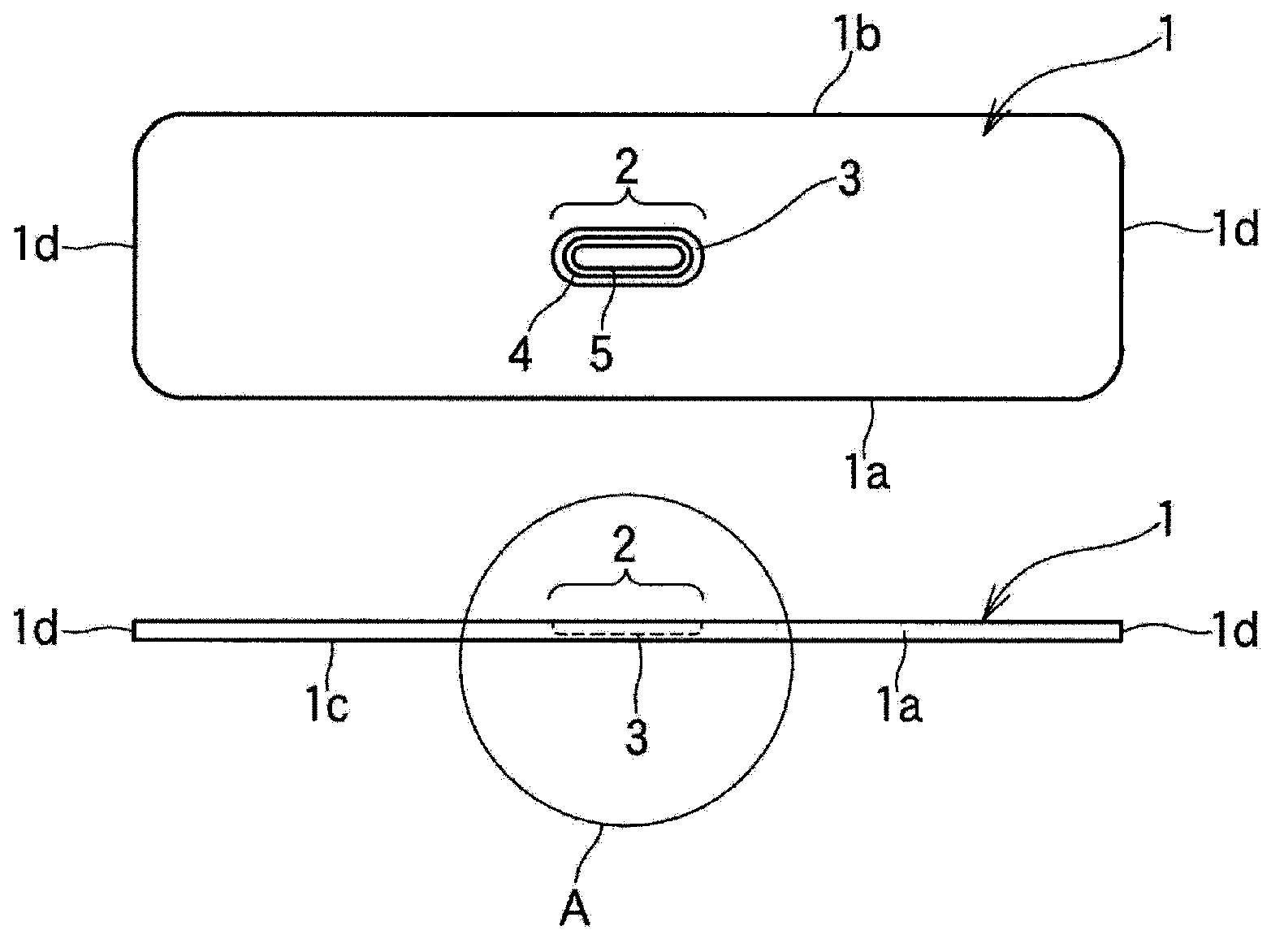

[0039]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the structural element which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0040] figure 1 , 2 Each embodiment of the battery case cover of the present invention is shown respectively, the upper side shows an overall perspective view, and the lower side shows a partial cross-sectional view thereof. Such as figure 1 , 2 As shown, the battery case cover 1 of the present invention is formed by forming an aluminum alloy thin plate with a certain thickness by press working, and has a flat plate shape as a whole.

[0041] Here, for the cover of the casing of the lithium ion secondary battery as the power source of the mobile phone, notebook personal computer or automobile, etc., the aluminum alloy thin plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com