Method for denitration of complexing ferroporphyrin smoke based on supergravity

A super-gravity and super-gravity machine technology is applied in the field of super-gravity complex ferrous flue gas denitrification, which can solve the problems of complex process route and high operating cost, and achieve the effects of simple process, good regeneration effect and high absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

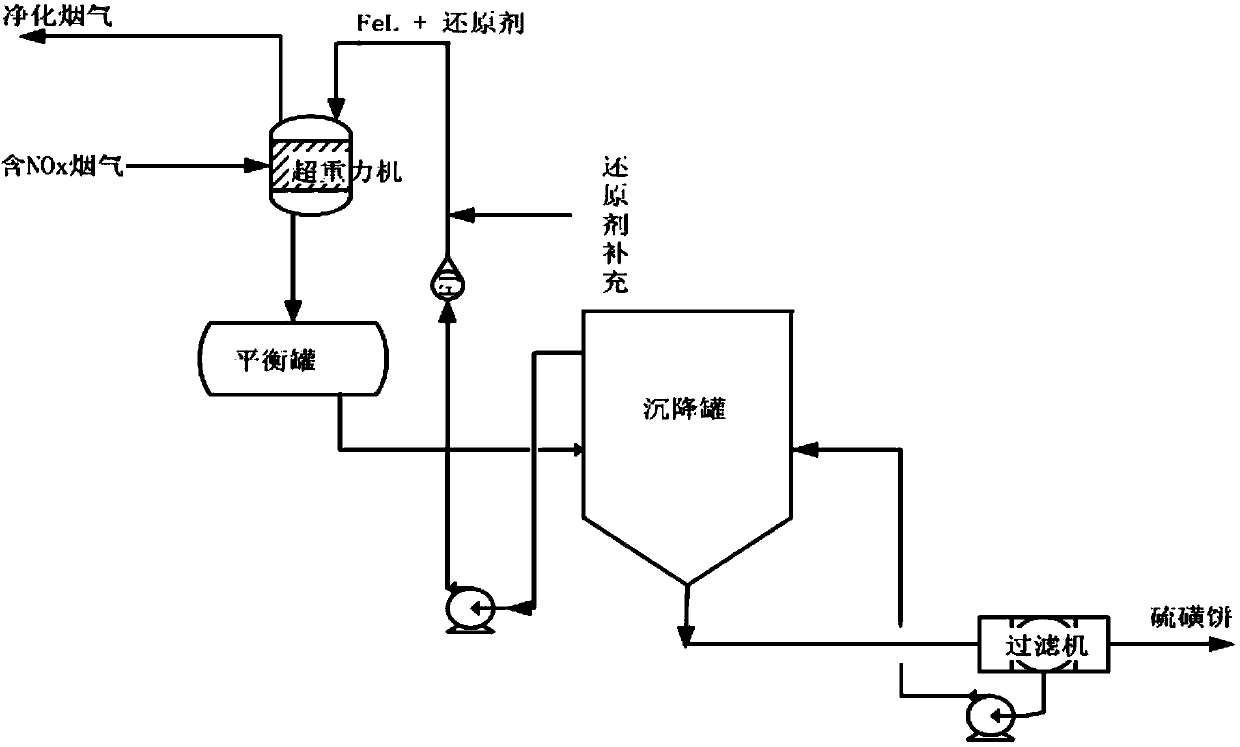

[0021] The method for the denitrification of flue gas by complexing ferrous iron in high gravity, such as figure 1 shown, including the following steps:

[0022] 1) After dedusting and desulfurization, the flue gas is 400Nm 3 The flow rate of / h enters the supergravity machine, the NOx concentration in the flue gas is 500-800ppmv, the flue gas temperature is 120, and the flue gas and the absorbent pumped into the supergravity machine from the storage tank through the pump are in the supergravity machine rotor packing layer Countercurrent contact, reaction denitrification; absorbent composition is HEDTA, sodium sulfide, Fe 2+ and Fe 3+ , the total Fe concentration is 0.01mol / L, the molar ratio of HEDTA to total Fe is 1.02:1, the molar ratio of sodium sulfide to total iron is 5:1, the temperature of absorbent is 20°C, and the volume ratio of flue gas to absorbent is 10:1;

[0023] 2) The purified flue gas after the reaction enters the demister from the gas phase outlet of th...

Embodiment 2

[0027] The method for the denitrification of flue gas by complexing ferrous iron in high gravity, such as figure 1 shown, including the following steps:

[0028] 1) After dedusting and desulfurization, the flue gas is 400Nm 3 The flow rate of / h enters the supergravity machine, the NOx concentration in the flue gas is 500-800ppmv, the flue gas temperature is 40°C, the flue gas and the absorbent pumped into the supergravity machine from the storage tank are in the supergravity machine rotor packing layer Countercurrent contact, reaction denitrification; absorbent composition is EDTA, sodium hydrosulfide, Fe 2+ and Fe 3+ , the total Fe concentration is 0.5mol / L, the molar ratio of EDTA to total Fe is 1.5:1, the molar ratio of sodium hydrosulfide to total iron is 4:1, the temperature of absorbent is 0°C, the volume ratio of flue gas to absorbent is is 500:1;

[0029] 2) The purified flue gas after the reaction enters the demister from the gas phase outlet of the supergravity ...

Embodiment 3

[0033] The method for the denitrification of flue gas by complexing ferrous iron in high gravity, such as figure 1 shown, including the following steps:

[0034] 1) After dedusting and desulfurization, the flue gas is 400Nm 3 The flow rate of / h enters the supergravity machine, the NOx concentration in the flue gas is 500-800ppmv, the flue gas temperature is 50°C, the flue gas and the absorbent pumped into the supergravity machine from the storage tank are in the supergravity machine rotor packing layer Countercurrent contact, reaction denitrification; absorbent composition is NTA, ammonium sulfide, Fe 2+ and Fe3+ , the total Fe concentration is 0.3mol / L, the molar ratio of NTA to total Fe is 2:1, the molar ratio of ammonium sulfide to total iron is 3:1, the absorbent temperature is 55°C, and the volume ratio of flue gas to absorbent is 1000:1;

[0035] 2) The purified flue gas after the reaction enters the demister from the gas phase outlet of the supergravity machine, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com